Last week, Energy-Storage.news quoted three departmental directors at US Department of Energy National Laboratory network facilities in a news story discussing how the country could establish a domestic value chain for stationary battery energy storage.

The key thrust of that article was that the US faces fierce competition globally and is heavily dependent on China for supply of everything from raw materials to finished products for lithium-ion batteries.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The US would be better placed to look beyond current lithium-ion technologies to newer, innovative electrochemical and other energy storage tech, according to the experts from Lawrence Berkeley National Laboratory (Berkeley Lab), Lawrence Livermore National Laboratory (LLNL) and SLAC National Accelerator Laboratory.

In the full interview, we talk in more depth about this and other topics: from the importance of getting the right batteries for the right applications, to the importance of deploying energy storage in the right places on the grid.

The trio of National Laboratory facilities, all based in California’s Bay Area, have partnered up to offer their collective expertise to battery innovators and manufacturers, each having different strengths and focus to their work.

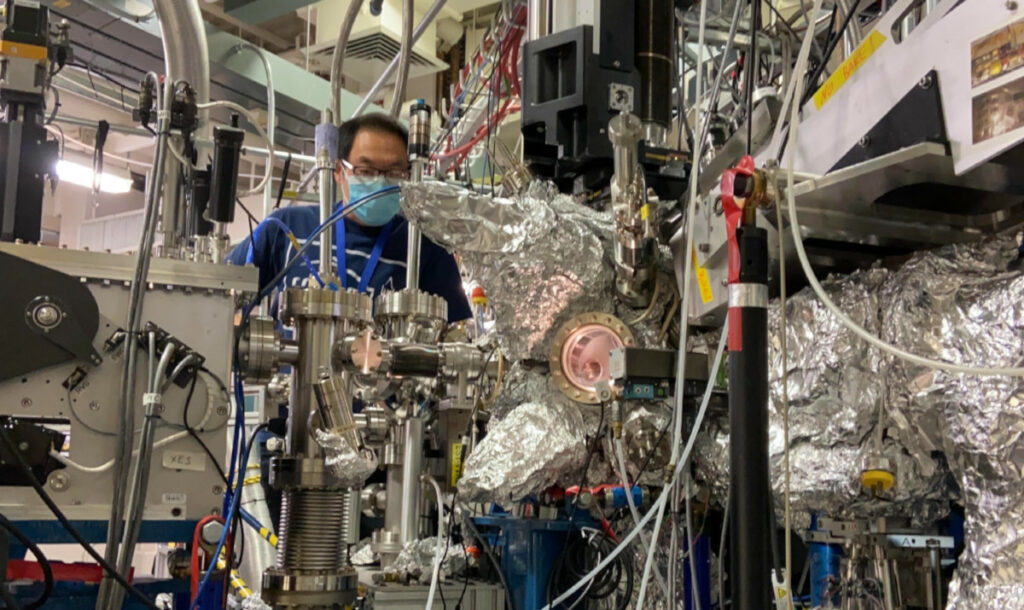

They are providing expertise, resources and technical assistance to companies across the entire battery value chain, from facilities including the SLAC-Stanford Battery Research Center, LLNL’s Laboratory for Energy Applications of the Future (LEAF) and the Berkeley Lab Energy Storage Center, with the latter home to more than 200 researchers.

That includes a major focus on batteries for other applications, such as electric vehicles (EVs), of course, but we decided to grill the three National Laboratory leaders for their thoughts and insights into what developing better batteries means for stationary energy storage and the decarbonisation of the power sector.

Interviewees:

- Steve Eglash, director, SLAC’s Applied Energy division

- Noel Bakhtian, executive director, Berkeley Lab’s Energy Storage Center

- Tony Van Buuren, deputy associate director for science and technology, LLNL

We’ve heard at some length about what battery materials analysis group Benchmark Mineral Intelligence has dubbed a “great disconnect” between growing demand for batteries and supply, particularly in supply of raw materials. What’s your perspective on today’s supply chains for lithium-ion batteries for stationary storage?

Steve Eglash: The dramatic growth of the battery manufacturing industry and of demand for batteries is being driven right now not by stationary storage, but by electric vehicles. In the not-too-distant future, it will also be driven by stationary storage.

No doubt there is a supply-demand imbalance for batteries, today. Why is it that automobile manufacturers in many cases aren’t able to get as many batteries as they want?

I think it’s manufacturing capacity more than raw materials. If we look at stationary storage, I think the main issue has to do with price and performance.

By and large, the lithium-ion batteries that are being built today for EVs don’t have the ideal combination of energy density, price per kilowatt-hour, ability to deliver high amounts of power.

My feeling is that while the batteries being manufactured today are more than sufficient for EVs, I think they’re still not quite what’s needed for stationary storage.

The thing that’s limiting a more rapid growth of stationary storage is not the supply chain, but rather that we don’t quite yet have the right batteries for stationary storage. I think we will in the next few years.

I think there are ones that maximise power density versus dollar rather than versus weight, right? Because weight matters for a vehicle, it doesn’t matter for stationary [applications].

It’ll also be technologies that work better, or discharge over 12 hours or 24 hours, or even 96 hours, as opposed to the shorter duration discharge needed for transportation.

I don’t want to minimise supply chain issues, but supply chain issues are impacting stationary and transportation applications differently.

Noel Bakhtian: What we’re seeing as far as shipping and ports, just the fact that we have to transport these things back and forth is just logistically hard and things are slowing down.

I agree that it’s a manufacturing issue, compounded with the fact that very little — to none — of the manufacturing is happening here in the US. It’s mostly European and in China. In fact, all the IP for manufacturing is coming out of China and Europe, etc.

What gets me excited is the global demand for batteries soaring and stationary storage is obviously a big piece of that. Numbers I’ve seen from BloombergNEF mean an investment of something like US$260 billion is needed by 2030.

That’s not necessarily going to be the same kind of storage as the batteries we see for cars. We’ve got teams working on hydrogen, we have teams working on flow batteries, on all these other types of, thermal energy storage, compressed air storage, etc.

The energy storage centre that I run at Berkeley Lab, we have two themes right now [that we’re working on], and one of them is actually supply chain. So we’re working very closely with the DOE and the other labs in the supply chain space.

So there’s a certain degree of needing the right technologies for stationary energy storage, really? They might exist today, but perhaps they’re not really commercialised or they’re not built at scale?

Noel Bakhtian: Stationary storage, if you’re talking about the two-to-four-hour ones, batteries fit well there. But, especially with the push towards long-duration energy storage that DOE is making and others in the last few years, I think that’s where some of the other technologies actually make a lot more sense as far as cost.

Steve Eglash: If we focus on electrochemical energy storage, things that look like batteries, or sort of first cousins of batteries, like flow batteries and fuel cells, the research is proceeding in parallel on multiple fronts.

At both Noel’s lab and my lab, we have large groups of researchers thinking about new chemistries, what’s often referred to as critical minerals and materials is a big part of that thinking.

Let’s think about materials that are Earth abundant, that can be obtained in environmentally friendly ways, that are available, either in the US or from friendly countries so we don’t end up overly dependent — or dependent at all — on countries that we don’t have long, trusted partnerships with, [and we need] a full lifecycle or cradle to grave to cradle analysis. That includes things like embodied energy recycling, reuse, all of those cradle-to-grave-to-cradle considerations, including the use of water. It’s a big, big deal.

As facilities in the DOE’s National Laboratory network, your work is presumably aligned with the goals of the Biden-Harris administration and Secretary of Energy Jennifer Granholm’s priorities. Recently we saw the Inflation Reduction Act passed which will incentivise domestic manufacturing, and shortly before that the Bipartisan Infrastructure Law was passed. What sort of impact might that have?

Steve Eglash: The Bipartisan Infrastructure Law is making available huge amounts of money for infrastructure, some of which is being put to work by the same DOE technology agencies that fund R&D.

Now, that doesn’t mean that those billions of dollars are going to Berkeley Lab, LLNL and SLAC, in most cases, the Bipartisan Infrastructure Law’s billions of dollars will go to companies and utilities and other organisations that are involved in deployment and scale up and impact. But the National Labs have a contributing role to play and those large amounts of money, those US$100 million-class grants, are helping to establish real scalable solutions on domestic shores.

Noel Bakhtian: US$7 billion of it went for batteries, US$3 billion is about to be out the door and we’re waiting on the remainder.

Across the sea, the European Union has also put billions into fostering its battery value chain domestically, with the European Battery Alliance being its leading instrument for doing that. Is that something you look to as an example?

Noel Bakhtian: They’ve actually put a lot more money into it, significantly more than the US$7 billion [the US has] and they’ve been working on this for a few, or even for many, years. We’re actually trying to follow them. We’re trying to take best lessons and lessons learned from them.

European Commission, Vice President, Maros Sefkovic, was here in the US and met with officials in DC. They came to an agreement about cooperating, and we actually hosted them out here at Berkeley lab with the European Battery Alliance leadership and did a whole roundtable with the California Energy Commission on how best we can collaborate.

Finally, one thing that really interests me is that we spoke at the beginning about demand for batteries being largely driven by the EV sector. Part of that will be because various countries are banning or limiting combustion engine car sales, along with the growing popularity of EVs with the public.

Whereas with stationary energy storage – and I know Berkeley Lab for example has quite a lot of capabilities in grid modelling and analytics – we have to all best figure out what the needs really are. There’s innovation, obviously, in the materials and the technologies for energy storage, but there also needs to be innovations in the grid, and there needs to be an understanding of what that right mix will be.

Do you have any thoughts on that, or can you tell us what the labs can contribute to that conversation?

Steve Eglash: It is a huge area of research at all three of our labs – and a priority for the DOE.

There is no doubt that much greater use of energy storage on the grid is going to result in a grid that’s more reliable, more resilient, better able to incorporate increasingly high levels of renewable generation that’s often not dispatchable.

And will support what we all call the energy transition, which includes not only more renewable generation, but also means the electrification of all kinds of things that aren’t currently electrified, like big industrial processes driven by thermal energy, for example.

So, there’s no doubt that we need a lot more storage on the grid.

I have a group that’s recently taken a look at the best available thinking of how much energy storage is needed to achieve certain levels of reliability and resilience on the grid. And they’ve concluded that adequate models do not yet exist for that.

There’s still a great deal of question where estimates vary over a really wide range, like a factor of 10 or more, of how much storage one actually needs to achieve a given level of reliability and resilience on the grid.

What I’m seeing leads me to believe that over the next few years, we’re going to see the emergence of research programmes to try and really nail down exactly the question you asked: how much storage do we need on the grid?

Noel Bakhtian: It’s also [asking] what kind of storage? Like not just how much, but what kind? What duration, which attribute of storage?

Tony Van Buuren: What you said about the grid leads into the whole national security aspect of things. So, a number of labs are part of the NARM, the North American Grid Reliability Model.

In NARM, they’re sort of saying, “Okay, if there’s an event that happens, how reliable is our grid?”

And it starts going down to like, “Okay, what does the storage needs need to look like? How is this robust against climate events? How what kind of storage do we need? Where do we need storage? How do we start incorporating climate resilience, because let’s say, we have a drought and our hydroelectric goes down in one part of the country?

It ties it all together. It’s national security, because it’s climate resilience, it’s energy storage, it’s incorporating new technologies, whether they be thermal, hydrogen, etc. And it crosses the gamut. I think that question captures why we are doing this to the degree [that we are]. It’s exactly why we’re doing this. It’s needed.