Fluence has entered a collaboration with solid-state lithium-metal battery startup QuantumScape, with the pair working together to develop stationary energy storage solutions using the new technology.

Solid-state technology offers the potential to increase energy density, charging time and safety of operation of lithium batteries, replacing the liquid electrolyte with solid material. Designing solid-state batteries that last a large number of cycles at scale and at low cost however has proven difficult so far.

QuantumScape claimed in 2020 to have made key breakthroughs in the technology and further advancements in 2021. Its partners include automaker Volkswagen, which has worked with the battery company since 2012 and has invested US$300 million into it to date.

Fluence, the market-leading energy storage technology and services provider with more than 3.6GW of storage deployed or under contract to be deployed around the world, has become the first non-automotive company to sign agreements with the startup.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

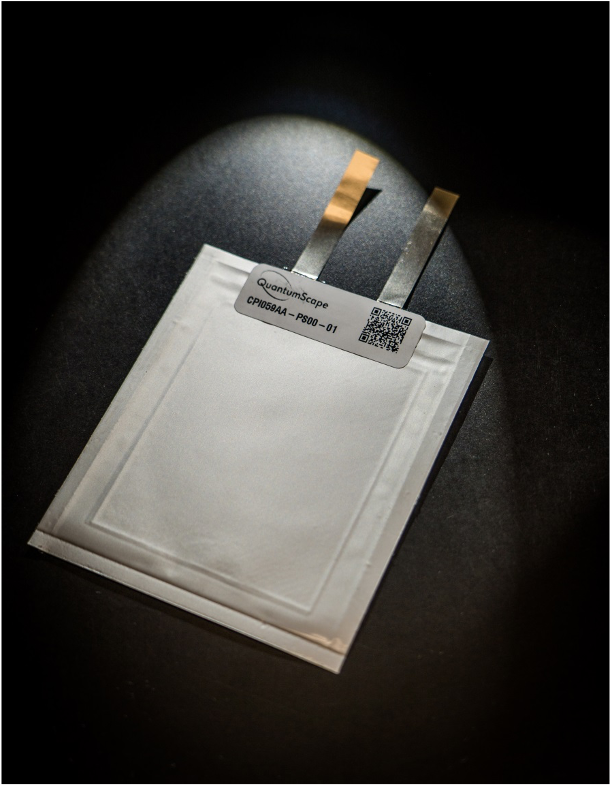

In QuantumScape’s design, a battery cell contains a cathode next to a solid state ceramic separator, instead of the porous polymer separator used in conventional lithium-ion batteries. In place of an anode, there is an anode contact plate.

When the battery charges, instead of lithium moving through a liquid electrolyte from the cathode to the anode, the lithium moves from the cathode through the ceramic separator and is deposited between the separator and the electric contact plate, creating a lithium-metal anode.

Doing away with the anode and liquid electrolyte reduces the physical footprint and weight of the battery. It’s the ceramic separator material that QuantumScape believes holds the key to enabling rugged solid-state batteries that can be mass produced for heavy duty applications like transport.

In the multi-year agreement signed with Fluence, the pair will collaborate on putting solid-state batteries into stationary energy storage solutions. Fluence will be an off-taker for batteries made at QuantumScape’s QS-0 pre-pilot production plant.

“While we have historically focused on automotive applications, we believe our battery technology is broadly applicable and can play a role in other sectors contributing to a lower-carbon future,” QuantumScape CEO and co-founder Jagdeep Singh said.

The companies will validate and test the battery tech and in a joint press release today announced that a large-scale supply agreement is expected to be made during their collaboration.

“As the team that invented battery-based energy storage on electric grids, it’s no surprise that Fluence is working with QuantumScape, the clear leader in the solid-state battery space, to bring its innovation to the power grid,” Fluence CEO Manuel Perez Dubuc said.

“Fluence’s technology-agnostic platform is also particularly suited to early adoption of next-gen technologies like this that have the potential to increase the adoption of stationary storage.”

Timelines for the collaboration or adoption of the QuantumScape cells were not given in today’s release.

“Fluence and QuantumScape share the same mission to reduce global greenhouse gas emissions through innovation and adoption of energy storage technologies, so our collaboration is a natural fit,” QuantumScape’s Jagdeep Singh said.

See below for a brief explainer video from QuantumScape. Source: QuantumScape YouTube channel.

Fluence shoring up supply chains

Ahead of an IPO in late October, Fluence revealed that it has 20GWh of contracted battery supply through 2024 from a number of “leading battery manufacturers around the world,” with its stationary storage solutions designed to work with numerous types of battery.

In April, the company announced a collaboration with European lithium battery manufacturing startup Northvolt to co-develop stationary energy storage solutions and for battery supply. Northvolt’s first gigafactory, Northvolt Ett in Sweden, began producing cells just before the end of last year.

In Energy-Storage.news’ recent Year in review 2021 series of blogs, Fluence CEO Manuel Perez Dubuc said that in 2021, supply chains, shipping and logistics issues were a challenge for energy storage companies — as they have been for every other industry on the planet.

The situation is starting to stabilise however, he said, and it is expected to normalise by Q4 of the 2022 calendar year.

“Ultimately, we believe this will be a brief speed bump in the clean energy transition and energy storage industries rather than a long-term disruption,” Manuel Perez Dubuc said.