Vertically integrated battery storage manufacturer CATL is working with ‘safety science’ specialist UL Solutions on the safer deployment of batteries for stationary storage and transport applications.

Announcing the formation of a strategic cooperation effort between the two companies today, CATL said the partnership should enable it to be able to conduct UL9540A fire testing in its own labs, under UL Solutions’ supervision.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

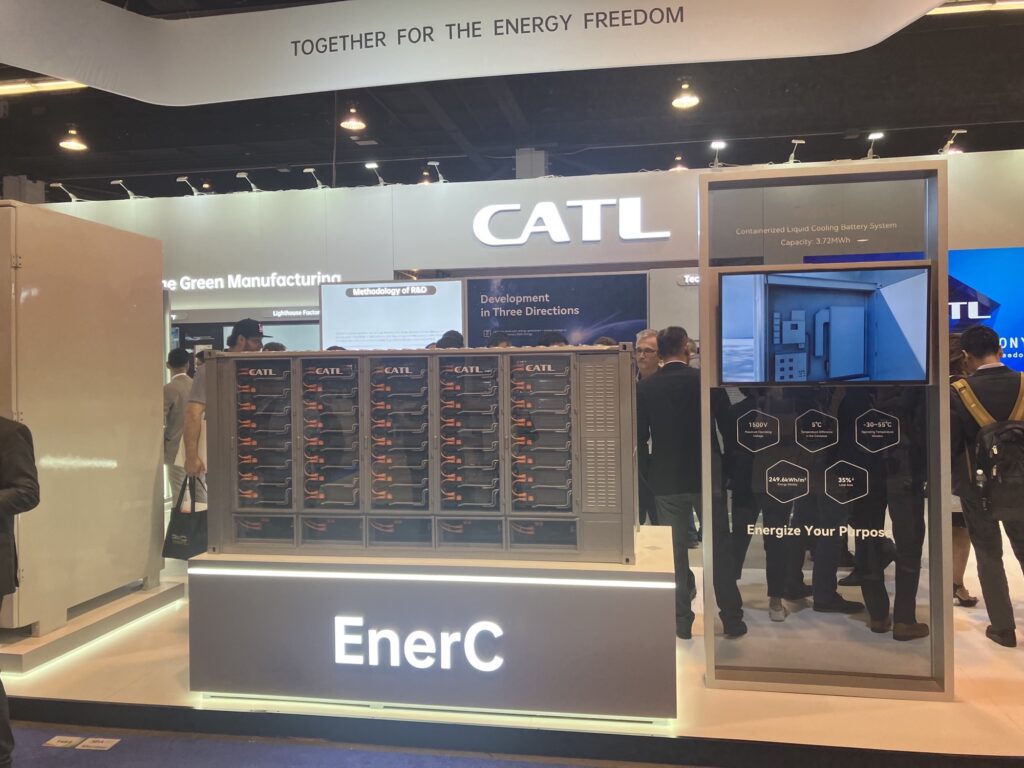

As the world’s biggest lithium-ion battery manufacturer, CATL is a key supplier to both the electric vehicle (EV) and the battery energy storage system (BESS) markets. As well as its battery cells, CATL makes and supplies battery storage racks, cabinets, and complete BESS solutions.

CATL was one of the two highest-ranked providers of batteries for stationary energy storage applications in the 2022 edition of the DNV Battery Scorecard.

Having signed a Memorandum of Understanding (MoU) with UL Solutions, CATL will begin working to get witness test data programme (WTDP) status, which is required to carry out the test.

UL9540A pertains to what happens to battery energy storage systems when a cell, or cells, go into thermal runaway. The test determines the ability of the system’s design to prevent fire caused by thermal runaway to propagate i.e., spread, to other cells and other parts of the BESS.

While there is no specific ‘fail’ or ‘pass’ criteria, UL9540A test data and findings are widely considered the industry standard for informing customers on system fire safety. Since last July, it has become a requirement under fire safety codes to have certification.

CATL said it is the first Chinese company to undergo the process, and already has WTDP status for three other key UL certifications, UL1973, UL9540 and UL2580.

In somewhat related news, KORE Power, a vertically integrated battery and BESS product manufacturer in the US, has claimed a “remarkable” fire testing result.

The company, currently building a lithium-ion battery gigafactory in Arizona, said that its Mark 1 battery module, when integrated into battery storage enclosures made by EV chargepoint specialist Veloce Energy, requires almost no side clearance as a fire safety measure.

KORE Power said this was proven out by UL, which conducted UL9540A testing on Veloce Energy’s 78kWh VPort battery storage system and found it required 0” clearance from combustibles.

That means the system, available in up to 468kWh configurations, or connectible in parallel to offer megawatt-scale storage, does not need wide spacing around it and could be safely deployed in compact sites, such as parking lots hosting EV chargers.

Veloce Energy CEO and co-founder Jeff Wolfe said the result “gives us the smallest footprint in the industry because the VPort does not require any dedicated clear areas to either side, and only requires 8” to the back”.

“This allows us to fit our BESS on an EV charging island, in the margin along the side of a building, or at the fence line of existing solar arrays,” Wolfe said.