Wärtsilä has been awarded a contract to deploy a battery storage system at a gold mine in Australia, marking the company’s first ESS project in the country.

The energy and marine sector technology company has become known as one of the major energy storage technology providers and system integrators alongside the likes of Tesla and Fluence in other markets, like the US, UK and more recently Southeast Asia.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The company has sold some of its thermal power engines to customers in Australia, including Zenith Energy, an independent power producer (IPP) that sells power to mine operators. Zenith previously bought three Wärtsilä dual fuel engines, which are used to provide constant load feed at Newmont gold mine in Tanami, northern Australia.

Yesterday, Wärtsilä said that Zenith has now ordered a 9.2MW / 8.7MWh short-duration battery energy storage system (BESS) solution, which will enable more frequent cycling of load, in conjunction with two new pure gas engines that the IPP has also ordered and the existing 65.98MW of dual fuel engines. The battery storage’s fast response times will be key to prevent the engines from having to be ramped so often, managing power fluctuations at the site.

This will result in fuel cost savings as well as streamlining fuel transport logistics, while the advanced energy management system (EMS) and BESS that Wärtsilä will install will be ready to integrate with renewable power assets in the future.

In common with other Wärtsilä BESS projects, the company’s own GridSolv Quantum modular battery storage units will be deployed, together with its GEMS Digital Energy Platform energy management and controls platform software, which can accommodate energy resources of any type, as long as they can be digitally controlled.

“Wärtsilä as the supplier of both engine and the energy storage systems provides the best solution available for us to feed power efficiently to our end customer. The addition of an energy storage system to also work as spinning reserve to provide emergency back-up and short duration power, will mitigate any power interruptions,” Zenith Energy technology and infrastructure manager Simon Jelly said.

“Should such situations occur, the system will supply load until a stand-by engine is started. Moreover, the storage system will help further reduce the plant’s carbon footprint.”

The project is scheduled to become operational in the first quarter of 2022 and Wärtsilä said the BESS will be delivered on an engineered equipment delivery (EED) basis.

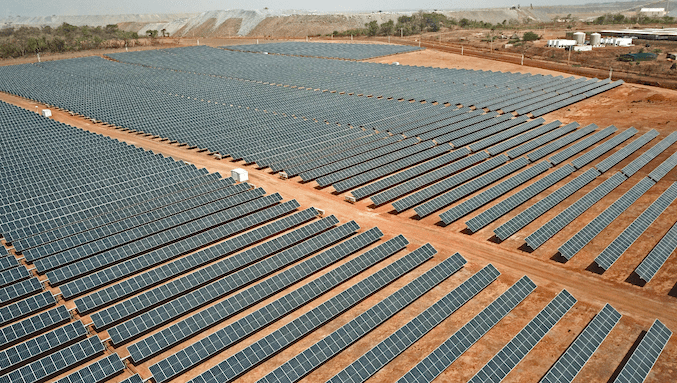

It’s the latest in a line of battery systems ordered to help power gold mines at various sites around the world. Most recently, the energy storage arm of Chinese solar inverter manufacturer Sungrow was awarded a contract to supply inverters and BESS equipment to a solar-plus-storage installation at a gold mine in Egypt. In April, installation was completed of a solar-storage-thermal power hybrid plant at a gold mine in Mali.

And it’s not just gold, various other types of mining operation are being supported in reducing fuel costs and carbon footprint with battery storage. With mines frequently in remote locations that are off-grid or have weak grid connection, but having fairly high electricity consumption, battery storage can be perfect to improve the efficiency of thermal power generators, to integrate renewables, or both.

Mini-gallery: Gold mines and battery storage

Here are a few recently completed projects that use BESS technology at gold mines…