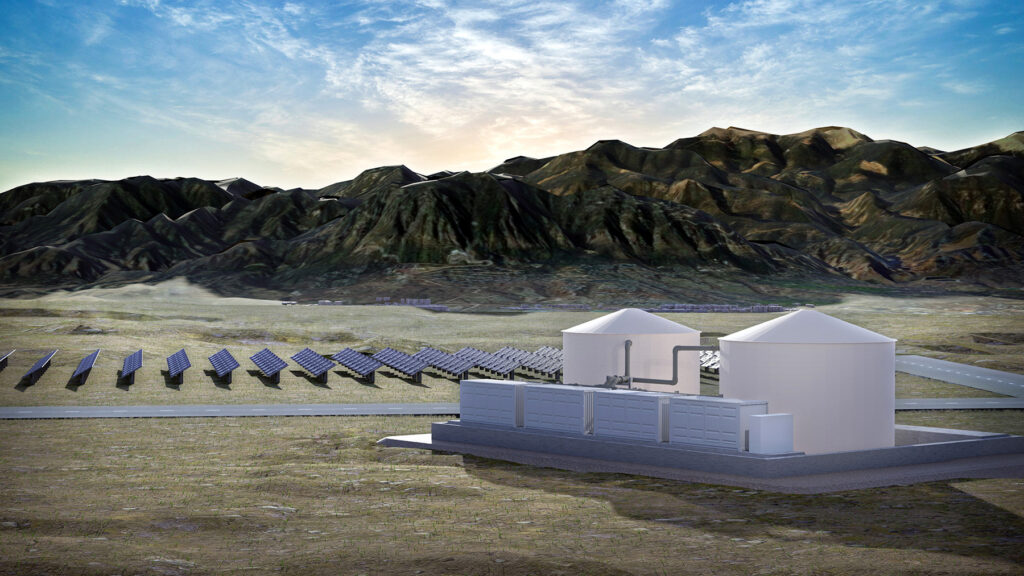

Construction has begun on a megawatt-scale flow battery project at the US Army’s Fort Carson in Colorado.

An event was held last week (3 November) to mark the breaking of ground at the project, which will see a 1MW/10MWh long duration flow battery energy storage system supplied by Lockheed Martin installed.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

It marks one of the first pilot projects for the aerospace and defense industry engineering specialist’s flow battery. Called GridStar Flow, Lockheed Martin had been developing the product behind closed doors for several years, since it acquired the assets of flow battery manufacturer and MIT spinout Sun Catalytix in 2014.

The first commercial-scale version of the battery system was installed at Lockheed Martin’s Andover, Massachusetts, testing facility in 2020. The first field pilot was announced in December 2021, a 6.5MW/52MWh (eight-hour) system at a solar PV plant in Alberta, Canada.

The Fort Carson project was announced in June this year. Over a two-year period, the flow battery will be run and assessed in accordance with protocols developed by Pacific Northwest National Laboratory (PNNL), in a tailored programme coordinated by utility Colorado Springs Utilities.

Lockheed Martin said when the project was announced that the anticipated construction time is eight to nine months.

The battery system will enable Fort Carson to reduce its draw of electricity from the grid at peak times, lowering its electricity costs and easing strain on the grid. Meanwhile in the event of grid outages, the flow battery will provide critical must-run and backup power to the fort.

It’s the largest long-duration energy storage (LDES) system to be installed at a US Department of Defense facility – defined as over six hours duration in this instance – but the battery’s chemical contents remain top secret.

Lockheed Martin has not revealed GridStar Flow’s electrolyte chemistry and only offered a few hints to the effect that it is more abundant material than commonly found in other flow batteries – the main types of which are usually vanadium or zinc-bromide – and cheaper.

In an online briefing with journalists, Lockheed Martin business development director Roger Jenkins also said the electrolyte’s composition is benign. Unlike vanadium which has to be dissolved in acid, the GridStar Flow electrolyte doesn’t cause significant wear and tear on balance of plant (BOP) equipment, Jenkins claimed.

“GridStar Flow, our long-duration energy storage system, is comprised of engineered electrolytes made from commonly available materials to enable durability, flexibility and competitive total cost of ownership,” Lockheed Martin VP for advanced programmes Steve Botwinik said at last week’s ceremony to launch the project.

The Construction Engineering Research Laboratory (CERL) at the US Army’s Engineer Research & Development Center (ERDC) will manage the Fort Carson flow battery system. ERDC awarded Lockheed Martin a US$17.5 million contract for the project.