Estonia-headquartered high-power energy storage startup Skeleton Technologies officially opened two European production plants in November.

The two factories, one in Finland, the other in Germany, manufacture different products based on Skeleton Technologies’ (Skeleton’s) supercapacitor and battery storage technologies.

The company claims its tech solves some of the key issues facing developers of data centres and grid storage, while its supply chain strategies onshore much of the value chain and do not depend on lithium, cobalt, manganese or other critical raw materials.

The tech company specialises in the design and production of ultracapacitors and supercapacitors, as well as high-power batteries. It holds the IP for Curved Graphene (CG), an active material that enhances the energy density of its energy storage devices.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

On 11 November, Skeleton announced the opening of a new factory in Varkaus, Finland, which is claimed to be the first in Europe to manufacture batteries specifically designed for AI data centre applications.

The Varkaus factory will make Skeleton’s SuperBattery. Pitched as combining the technical capabilities of a battery and a supercapacitor, it can charge in under 90 seconds with a 50,000-cycle lifetime.

At a launch event, Skeleton Technologies CEO Taavi Madiberk said the rapid charging capability is crucial for managing the fluctuations in power supply that AI computing loads can create.

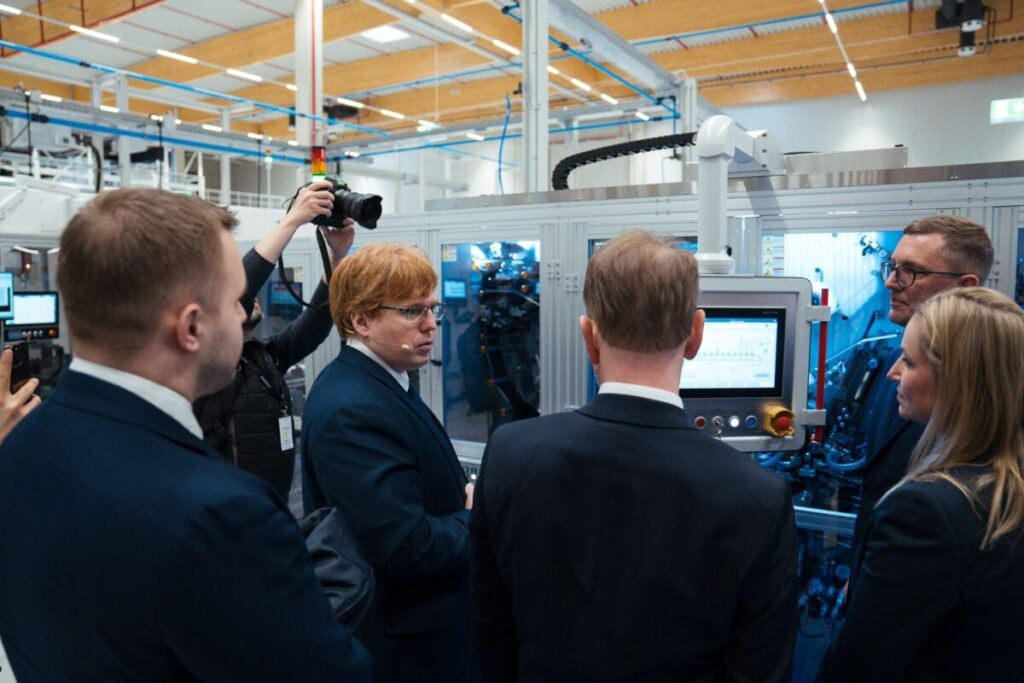

Last week (28 November), the company opened its new SuperFactory near Leipzig, Germany. SuperFactory makes Skeleton graphene-based supercapacitors. These are used in GrapheneGPU, Skeleton’s graphics processing unit (GPU) that cuts electricity consumption by nearly half compared to competitor products, the company claims.

GrapheneGPU enables AI data centres to “cut total electricity consumption by up to 44% by smoothing power peaks and reducing stress on the electrical grid,” CEO Madiberk said.

“At the same time, it keeps a core part of the value chain in Europe. By eliminating power peaks and overheating, GrapheneGPU unlocks 40% more computing power from the same investment in NVIDIA, AMD, or other GPUs,” Madiberk said.

The company’s premise is that fast-responding technologies like supercapacitors can ease the strain on grids created by the “perfect storm” of accelerated renewable energy adoption and growth in electricity demand for AI data centres.

“When it comes to the electrical grid, our mission is simple: keep the lights on in Europe,” the CEO said, adding that transmission system operators (TSOs) in Germany already use Skeleton’s systems “as a last line of defence, a real safety belt for a grid increasingly powered by renewables.”

Skeleton has invested around €50 million (US$58.16 million) in its 1GW annual production capacity SuperBattery factory in Finland. The Leipzig SuperFactory required around €220 million investment and will produce around 12 million cells annually. The factory in Germany is already supplying products to customers Siemens, General Electric and Hitachi Energy for work on European grids, as well as to unnamed hyperscaler data centre developers in the US.

Posting to LinkedIn today, CEO Madiberk said the Leipzig factory, where 420 people will be employed, is “a clear demonstration that Europe can still build big, fast, and at scale.”

“The Leipzig SuperFactory gives us the ability to scale rapidly to meet surging demand from AI data centres, grid operators, heavy mobility, and defence, all while building a supply chain that is fully European and free of critical raw materials.

“If we want to win in Europe, we can’t copy/paste the US and China, we need a European way. We shouldn’t focus on catching up, but on winning with products which are not best in Europe, but best in the world!”

Back in 2020, Energy-Storage.news hosted a sponsored webinar on the potential of ultracapacitor technologies for stationary energy storage applications, with European Union technology investment accelerator EIT InnoEnergy.

US ultracapacitor company Maxwell Technologies recently changed hands and was bought by low-voltage battery solutions firm Clarios, reportedly to help the buyer build up its US-based value chain.