Closed-loop pumped hydro energy storage (PHES) has fewer emissions associated with its development, construction and use than other leading options for large-scale energy storage.

That’s according to new analysis from five experts at the US National Renewable Energy Laboratory’s (NREL’s) Strategic Energy Analysis Center. The team has carried out what is claimed to be a first-of-its-kind assessment of the life cycle of closed-loop PHES, and published its findings in the journal Environmental Science and Technology.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

While pumped hydro is the longest established storage technology used widely on the grid in the US and the rest of the world, still representing the largest share of the storage market by capacity, few studies have been conducted into its impact on greenhouse gas (GHG) emissions.

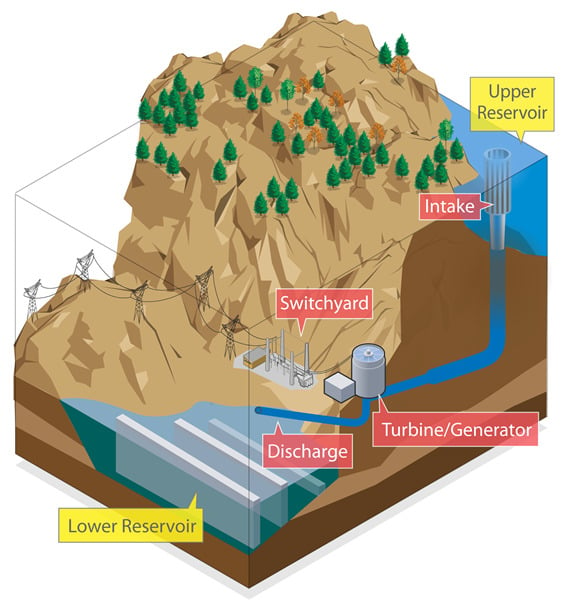

Pumped hydro technology is simple and effective. PHES installations comprise two large bodies of water, one above the other, and water is run down from the upper level to the lower reservoir and passed through turbines to generate electricity.

When it comes to ‘recharging’, the water dropped into the lower reservoir is pumped back up, hence the name. Speed and quantity of water down through the turbines can be managed so that pumped hydro plants can provide hours of storage duration.

However, the costs, time and nature of the large engineering project they represent, as well as the need for specific topography means pumped hydro can’t be built anything like as quickly as, say, lithium-ion battery energy storage system (BESS) assets.

As of 2019, the US had 22.9GW of PHES on the grid. Lithium-ion batteries are its closest rival today, having reached an installed base of 9GW/25GWh by the end of 2022, according to figures from the American Clean Power Association (ACP).

Comparison with three other technologies

NREL’s researchers looked specifically at closed-loop pumped hydro. ‘Closed-loop’ refers to the source of water, meaning that the PHES plant is “not continuously connected to a naturally flowing water feature”, according to a US Department of Energy (DOE) definition. As seen in the diagram above, an open-loop PHES plant would conversely be connected to a body of flowing water.

Closed-loop PHES was compared with compressed-air energy storage (CAES), utility-scale lithium-ion (Li-ion) battery storage, utility-scale lead acid batteries and vanadium redox flow batteries (VRFBs).

Taking a base scenario in which the electricity mix on the grid is 100% renewable energy, NREL’s researchers looked at 39 preliminary designs for 35 different proposed PHES sites in the US. It was assumed that a PHES plant would have an output of around 835MW and energy storage capacity of 2,060MWh on average.

Including materials and construction, closed-loop PHES was found to have lower global warming potential (GWP) than all three other technologies, with lithium-ion second, VRFBs third, CAES fourth and lead acid in fifth place. This was based on emissions per kilowatt-hour (kWh) of electricity stored, with closed-loop PHES found to have a GWP of between 58g to 502g of CO2 per kWh.

Today, driven by the need to store increasing amounts of energy to help integrate growing shares of variable renewable energy (VRE) generation from solar PV and wind, PHES plants are making a comeback around the world.

New large-scale PHES projects are in construction or have recently gone into commercial operation in regions including India, Australia, China, Portugal and Spain, while several are in development in the UK, Canada and the US. Another recent report from NREL, this time in collaboration with Argonne National Laboratory, found that Alaska alone holds the potential to host up to 1,800 pumped storage hydropower sites.

Different energy storage technologies are often put to different applications. For instance, lithium-ion batteries are very good at high power applications that require very fast response times, while pumped hydro’s main role tends to be in providing high energy requirements for long-duration energy storage (LDES).

The NREL team acknowledged this, but taking the example of compressed air, report author Daniel Inman said that although CAES is used for different services PHES doesn’t provide, such as grid inertia and grid resilience, emissions from PHES are nonetheless about four times lower than from CAES.

The full report, ‘Life cycle assessment of closed-loop pumped hydropower in the United States’ by NREL’s Daniel Inman, Gregory Avery, Rebecca Hanes, Dylan Hettinger, and Garvin Heath can be found here.