The energy storage subsidiary of Croatia-headquartered electric vehicle (EV) company Rimac has officially launched its modular battery energy storage system (BESS) product.

Rimac Energy last week (17 October) officially announced SineStack, which it had previewed to the industry at the Energy Storage Summit Central and Eastern Europe earlier this month, claiming it to be the “most technically advanced” product of its type.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The parent company is better known for supplying components and systems for electric cars including models from luxury brands including Jaguar, Porsche and Aston Martin. Subsidiary Rimac Energy was unveiled to the market in May, with 60 employees hired and designs on supplying to the utility-scale, commercial and industrial (C&I) and battery-integrated EV charging segments.

At that time, Rimac said it would begin high volume production of energy storage system (ESS) technologies at its campus in Croatia, targeting 10GWh of annual production capacity by 2025.

Then, at the summit hosted by our publisher Solar Media in Warsaw, Poland, Rimac product engineering manager Roger Moorhouse offered the audience some details of its flagship SineStack solution for utility and C&I applications.

The product will use lithium iron phosphate (LFP) cell chemistry batteries, with each unit featuring 790kWh energy storage capacity and 400kVa output, while the batteries would be able to handle up to 12,000 cycles and achieve AC round-trip efficiency of over 92%.

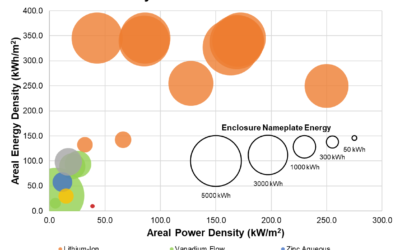

It also includes a distributed inverter topology architecture which means it acts as an ‘AC battery’, allowing inverters to independently control battery cells in blocks of 18. Meanwhile, the inverters in the power conversion system (PCS) are integrated directly with batteries, helping enable energy density of 280kWh per square metre.

According to Moorhouse, Rimac’s high levels of vertical integration with “virtually no boundary between the battery and the inverter” meant it was able to achieve some claims of ‘best-in-class’ tech for SineStack, which he said is a “software-defined product”.

Rimac’s official launch last week confirmed the spec that Moorhouse had previewed. It also mentioned some other claimed advantages, such as the Integrated Power Conversion technology allowing customers to add further 790kWh blocks to their systems without inverter changes or additions.

Certainly higher levels of integration between battery and inverter/PCS are being seen as desirable by the energy storage industry, with one example being system integrator Powin’s acquisition of PCS maker EKS Energy a while back. Energy-Storage.news has heard from representatives of Powin and other system integrators like LS Energy Solutions that while inverters comprise a small portion of a project’s overall cost, they can have an enormous bearing on its success or failure.

“SineStack is the result of a clean-sheet design in hardware and software and multiple years of R&D. It pushes the limits of what grid-tied batteries can offer customers,” Rimac Energy director Wasim Sarwar Dilov said.

The company’s initial production ramp target appears to have shifted since that initial May announcement, and according to Roger Moorhouse Rimac will begin mass production in 2025 with 300MWh annual capacity, rising to 1GWh within a year and targeting 10GWh+ at a future, unspecified, date.

Pilot with ENNA to begin next year

Rimac also said it plans to partner with Croatian energy company and renewable energy investor Energia Naturalis (ENNA). A pilot project will be delivered to one of ENNA’s sites in 2024, with the aim of informing the pair’s implementation plans.

In other words, Rimac intends ENNA to be the first to bring its BESS product to market, Dilov said, “accelerating the deployment of clean, renewable, resistant and low-cost energy in Southern and Eastern Europe”.

In an earlier statement, issued in September, ENNA had said the pair’s shared goals include the deployment of 1GW of energy storage systems.

While ENNA Group is involved in a number of different businesses including locomotive transport and fruit and vegetable distribution, various media reports earlier this year stated the company is preparing an IPO and is making significant investments into renewable energy projects with a view to investing €1 billion (US$1.06 billion) into green energy projects in Croatia.

“Rimac Technology is renowned for pushing boundaries in electric vehicles components industry and with SineStack now setting off to introduce the next generation of ESS,” Zoran Miliša, CEO of ENNA’s energy provider subsidiary ENNA Opskrba, said.

“The proposed partnership aims to propel us forward in making renewables, backed by cutting-edge storage technology, a cornerstone of Croatia’s energy landscape.”

At the recent summit, the potential of the storage market in Central and Eastern Europe was much-discussed, while southern European countries including Greece and Italy are emerging as markets with a good combination of fundamental drivers for renewable energy deployment and policy and regulatory support for the role energy storage can play in their energy systems.