A new service from Photovoltaik Institut Berlin (PI Berlin) looks to solve a pitfall that often awaits solar industry stakeholders when adding energy storage to their projects: making sure the production quality of the batteries they choose meets their requirements.

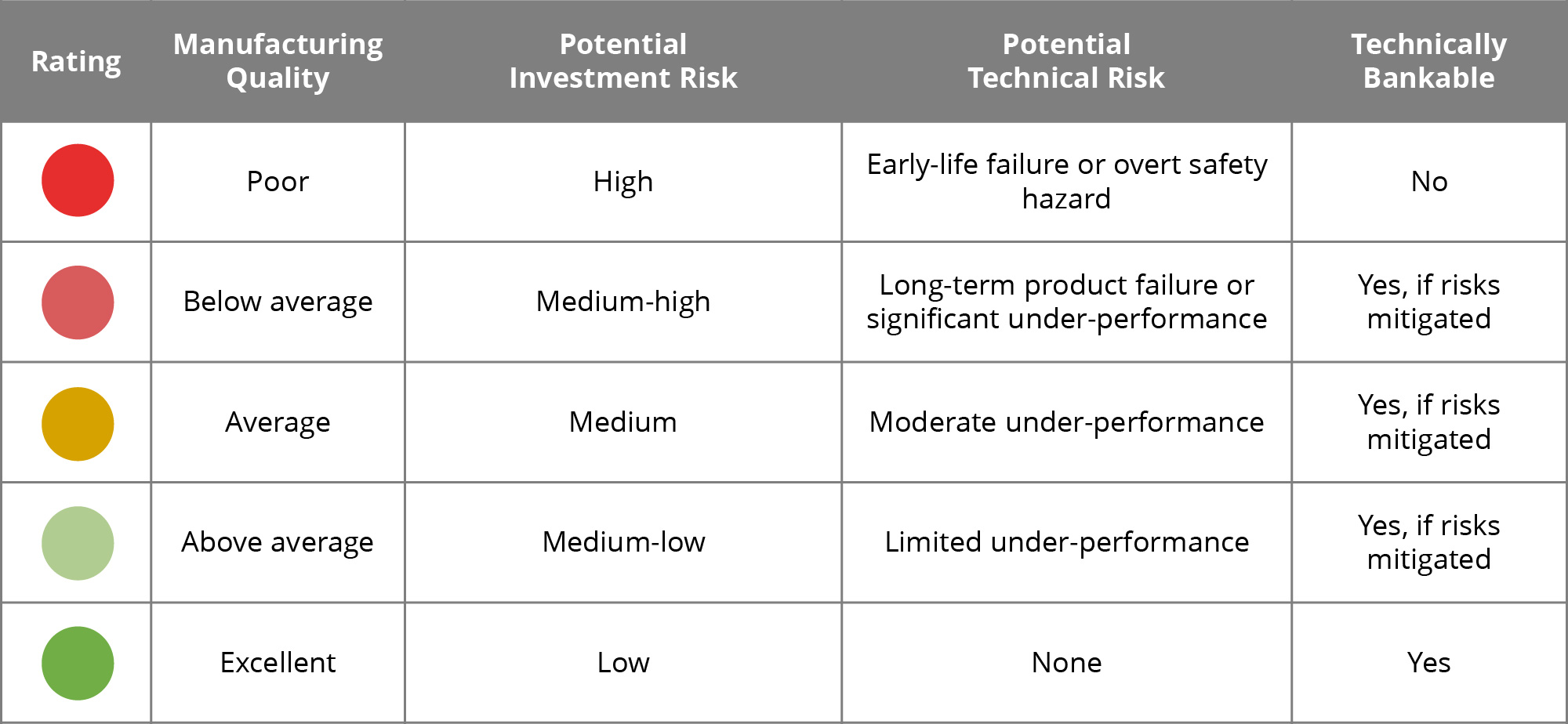

Independent technical diligence and quality assurance provider PI Berlin said its assessment service of the production quality of lithium-ion batteries and battery systems is a “deep dive” which can provide targeted risk mitigation advice to project owners and investors as well as revealing any potential “weaknesses” in battery production.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The diligence service aims to do complete factory audits for assessment and mitigation of those risks – which can impact on safety as well as economic decision-making.

“The needs of battery storage users in the solar industry are demanding in terms of long-term performance and reliability expectations,” A PI Berlin representative told Energy-Storage.news today.

“PV systems are expected to operate for at least 25 years. This puts high demands on the quality of the batteries and their ability to withstand the rigors of daily use for extended periods of time.”

Ian Gregory, PI Berlin North America’s managing director said in a press release that for batteries to be safe and provide good performance long-term, every manufacturing step needs to be carried out correctly. Temperature and humidity of raw materials storage, purity of chemical electrolytes, uniformity of electrode coasting and many other factors can impact on the finished product.

The PI Berlin representative that this site spoke to said that as widely-applied international standards for batteries – particularly for those paired with solar applications – do not exist, independent assessments “are a valuable tool in helping to ensure long-term battery life for major buyers or investors in the solar industry.”

The representative confirmed that the service will take into account the different ways of measuring battery performance and suitability for different applications which could include high cycle-rate use cases or fast-response to provide frequency regulation and so on. The representative said PI Berlin is “paying close attention to the in-factory acceptance testing of batteries to ensure their fit, for use in specific applications”.

The service is “battery focused” and does not include power management and power conditioning systems however, which the representative said are often project specific.

“We include everything from individual battery cells to completed battery racks and the battery management system (BMS),” the PI Berlin representative said.