The development of global standards and specifications for the electrolyte used in vanadium redox flow batteries (VRFBs) is “crucial” for the technology’s prospects.

That’s according to Vanitec, a trade association promoting the use of the transition metal vanadium in materials used across various industries, including flow batteries for stationary energy storage system (ESS) applications.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The non-profit group, headquartered in the UK, commented last week (5 March) on an ongoing project to develop VRFB electrolyte standards and specifications by the International Electrotechnical Commission (IEC).

Vanitec said the IEC project, which is being undertaken with input from Germany’s Fraunhofer Institute and industry stakeholders, will address a key gap in the industry. The trade group said the current lack of a consistent global standard is leading to disparities in quality and inefficiencies in production and could create performance issues.

Flow batteries using vanadium-based electrolyte—as well as several flow battery technologies that use different electrolyte chemistries based on materials including iron and various organic compounds—are being positioned by manufacturers as a potential alternative to lithium-ion (Li-ion) for electrochemical energy storage applications that require medium- and long-duration energy storage (LDES).

The upfront capital expenditure (Capex) requirements of flow batteries are higher than those of their Li-ion counterparts, which is one reason why adoption has been slow by comparison.

Last year, BloombergNEF (BNEF) undertook its first-ever cost survey of LDES technologies, with flow batteries among them. BNEF found that, in 2023, flow batteries had an average fully installed cost of US$444/kWh versus an average Capex requirement of US$304/kWh for lithium-ion BESS at 4-hour duration.

Liquid electrolyte enables decoupling of power and energy

However, industry participants and advocates argue that because of factors including the ability of VRFBs to undergo heavy cycling over projected 25-year lifetimes or more without degradation or capacity fade, their total cost of ownership can be competitive.

Unlike lithium, where thermal runaway in individual cells can cause fires or even explosions, flow batteries instead rely on tanks of liquid electrolyte which the industry says carries no fire risk.

Furthermore, the energy storage capacity of flow batteries can be increased by scaling up the size of electrolyte tanks, whereas Li-ion battery energy storage systems (BESS) require additional cell stacks, along with associated power electronics and other balance of plant (BOP) equipment such as thermal management systems.

The decoupling of energy from power means the cost of adding more capacity to a flow battery is incremental instead of requiring a doubling of equipment costs.

BNEF’s May 2024 survey highlighted that flow batteries become more cost-competitive at longer durations, particularly up to around a 12-hour discharge duration at full-rated power.

A debate is currently ongoing in the industry as to whether lithium-ion can perform the LDES applications that flow batteries and other technologies, such as liquid air energy storage (LAES), are positioning themselves for.

Two experts from Li-ion BESS provider Envision made this case in a Guest Blog for Energy-Storage.news published last week. Wins in state government tenders in California, US, and New South Wales, Australia, for long-duration storage contracts have so far been dominated by lithium-ion project bids.

Also in Australia, global infrastructure investor Quinbrook and Li-ion battery and BESS manufacturer CATL recently partnered to market long-duration lithium technologies for the country’s emerging opportunities.

That said, Envision’s Kotub Uddin and Sam Secher were focusing on applications requiring up to 10-hour duration in their blog, and the aforementioned tenders sought 8-hour projects, the same duration the Quinbrook-CATL partnership is targeting.

Flow battery advocates also argue that, being decoupled from the lithium battery supply chain, the technology could offer an alternative to potential procurement constraints as global Li-ion BESS demand continues to accelerate.

China currently leading flow battery race

Meanwhile, although the results of the IEC project, headed up by a working group led by Fraunhofer ICT scientist and engineer Jens Noack, are not expected for the next one to two years, Vanitec said its work could be essential in making flow batteries scalable and commercially viable.

“A clear and accepted standard will not only improve quality control but also foster investment, innovation, and pave the way for the adoption at scale of this very import decarbonising technology,” director Terry Pearles at high-purity vanadium processing company and Vanitec member US Vanadium, said.

In April 2024, Jens Noack posted to his personal work website that IEC members had accepted the IEC New Work Item Proposal ‘Electrolyte for vanadium flow batteries,’ “which means that we will start developing a new international standard for vanadium electrolyte.”

The working group is set to meet next week in Tokyo, Japan, for a three-day session, and Vanitec urged industry players to “align with these developments early to ensure compliance and position themselves for long-term success in the growing LDES market.”

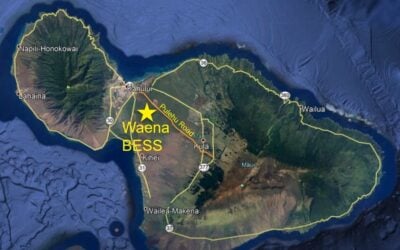

China currently leads the global VRFB market. It is home to its biggest projects, such as Rongke Power’s 157MW/700MWh grid-forming system, which went online recently, the country and is a major mover in the production of the vanadium metal itself.

BNEF said that the average cost of a fully installed flow battery system in China was around US$423/kWh in 2023. When China was removed from calculations, the worldwide cost averaged US$701/kWh in the survey.

Vanitec noted that China already has standards for VRFB electrolyte, which is typically made using the compound vanadium pentoxide, but the trade group said the Chinese standards allow for a wider range of purity standards than the IEC-convened project will aim toward.

Vanadium can be extracted directly from the ground or made as a byproduct of steel production, with the latter secondary source partly accounting for China’s global dominance. However other countries such as Brazil and South Africa are home to major primary vanadium deposits, along with Queensland, Australia, which is thought to hold about a third of the world’s primary vanadium resource.

The Australian state has sought to position itself as a hub for both vanadium metal resources and flow batteries, supporting the construction of both battery and electrolyte production facilities, although a recent change of state government administration means an uncertain future for Queensland’s clean energy initiatives including its Battery Strategy may lie ahead.