The phrase ‘game changer’ is used often, sometimes in hope rather than expectation. Lithium batteries have definitely changed the game for the energy transition, but require smart technologies and strategies to optimise them — which can be equally important — writes Sebastian Becker of TWAICE, a predictive analytics software provider.

This is an extract of an article which appeared in Vol.28 of PV Tech Power, Solar Media’s quarterly technical journal for the downstream solar industry. Every edition includes ‘Storage & Smart Power,’ a dedicated section contributed by the team at Energy-Storage.news.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

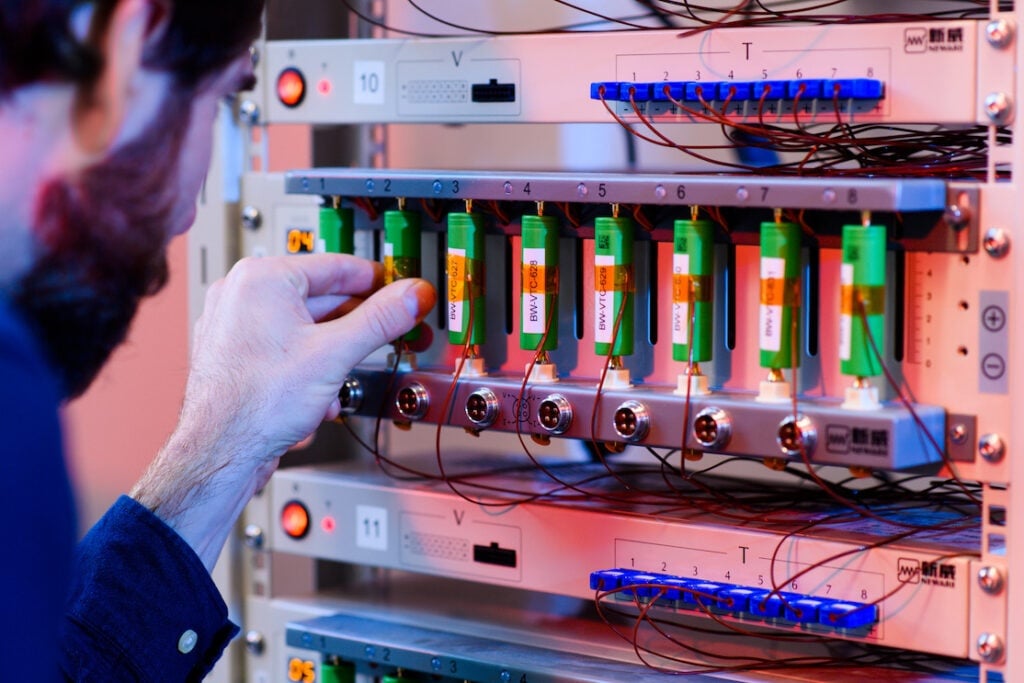

Battery storage systems are an essential component of the energy sector. However, they are complex systems that require special attention. The primary goal of storage owners is to maximise the profit possible from the storage system without taking on additional risk. This is where battery analytics comes into play.

Booming market

Around 25GWh of stationary battery storage is already installed worldwide. This will rapidly increase, as battery storage systems are ideally suited to address the challenges of the energy transition. Unlike most other power plant technologies, batteries can not only supply energy, but also store it. And they can respond to the need to do so within milliseconds.

This makes them suitable for numerous use cases, both front-of-the-meter and behind-the-meter. In addition, falling battery prices make investments more attractive. Combined, these factors fuel a boom in battery storage that is likely to reach hundreds of gigawatt-hours by 2030.

However, many market actors – system integrators, asset owners, partners and financial service providers – identify the main reasons for a decision not to move forward with a battery project as technical risks in conjunction with market challenges and a changing regulatory environment. Market risks involve fluctuating prices, while new regulations can destroy a business case (or sometimes also send it through the roof ). One example of a bulletproof business case is California. Here, market risk was all but eliminated by the revenue of most projects being protected by long term power purchase agreements (PPAs).

Consequently, projects with hundreds of megawatt-hour capacities are no longer rare. But while being subject to these external market factors, with any battery storage project, careful assessment of the impact that the use case will have on the battery is required.

Challenges of technical risks

Batteries are complex electro-chemical systems and come with some technical challenges. As a new asset class, many players that have never dealt with batteries before now find that they are essential to their success.

To ensure a common understanding, let’s establish a few facts:

- Battery storage is generally a very safeand reliable technology. However, like any other technical system, battery cells or other components can fail. The consequences depend on the severity and the reaction. Best case, moderate reduction in performance or unplanned maintenance. Worst case, if the issues are not immediately addressed or an essential component fails without warning: unplanned downtime with major repairs. One eye-catching example is battery storage fires, e.g. in Korea and Arizona (2018 and 2019, respectively) which attracted a lot of media attention. The probability is less than 1:1,000,000 but if it happens, it can be a disaster.

- Downtimes are a technical risk that translates directly into financial risk. While downtime may not seem dramatic at first glance, certain use cases depend on the availability of a battery. When energy is not available when required, penalties due to breach of contract are incurred or, more simply, a very high bill is incurred. Energy solutions that include battery storage can save a high percentage of a company’s electricity bill – if the storage fails during peak time there are no savings for that year (and the company still pays for the storage).

- At an advanced stage of the battery lifetime, there is the risk that power or capacity requirements are not met anymore. This results in the exclusion of certain markets and use cases, but also contains the risk of unexpected penalties.

Existing warranties can only partially address these challenges or become prohibitively expensive, as it is impossible for the insurer to assess the risk. In short, batteries come with great opportunities but also high, yet manageable, risks. Let’s take a look at battery analytics to understand why.

Why is battery analytics so important?

Battery degradation, also called ageing, has a significant impact on performance over the lifetime. In time, two major effects become visible: capacity fade and resistance increase, translating to less available energy and power. The overall capabilities are often collectively measured in a KPI called state of health (SoH).

This ageing behaviour and state of health is driven by numerous factors and can vary greatly from one battery system to another. Two batteries with 90% SoH may have wildly different remaining useful lifetimes, depending on their previous treatment. Let’s look at some of these factors:

- Temperature: This has a large impact but depending on the situation andcell (chemistry) different temperature ranges can be beneficial. As a rule of thumb: When the battery is idle, low temperatures are preventing too much calendric ageing i.e., ageing that occurs with time without usage, while moderately warm temperatures (e.g. 30°C) may be the best option for strong cycling.

- Charging rate (c-rate): Different battery types are used for different use cases. In general, high c-rates tend to have a greater impact on ageing than low c-rates.

- Average State of Charge (SoC): While it is desirable to have a lot of energy available (depending on the use case), higher average SoCs may accelerate the ageing. Too low SoCs may threaten the business case, as not enough energy is available. Too low SoCs should always be technically prevented by the battery management system to prevent damage.

- Depth of Discharge (DoD): This refers to the amount of energy that is taken out of the storage at any given time. In a battery discharging from 80% to 35% SoC this translates into a DoD of 45%. As a rule, lower DoDs are beneficial with five swings of 20% being less harmful than one full cycle. Thus, 10 cycles in an arbitrage operation will have a larger impact on battery degradation than 10 cycles in ancillary services.

But the reality is more complicated. Every battery type reacts very differently to each of these stress factors. And if – to prevent battery degradation – the battery is operated ‘over-carefully’ regarding the described stress factors, a lot of potential is wasted.

So why not simply put a lot more capacity into the storage (called oversizing, or overstacking) from the beginning? Firstly, because the initial investment costs will skyrocket and ruin your business case. Most users will aim to leverage as much of the storage as possible.

Which leads to the second point: While a couple of years ago, the optimisation for a specific use case upfront may have been a valid idea, use cases have since become more complex. Multi-use strategies, or a change of operating strategy after a while, will become mandatory for high profitability. As a result, dimensioning the system at the outset has become less important and dispatch planning is happening regularly, requiring new insights into the current battery capabilities and the impact of different operating strategies.

An essential differentiator in a competitive market

There is a lot of untapped potential in a market with increasing volumes, decreasing prices and an increasing consolidation – not surprisingly, this had led to strong competition and there are still many new players trying to gain a foothold in this dynamically growing and evolving market. Competitive pricing has become a necessary requirement to exist in a market with both powerful suppliers (battery and PCS manufacturers) and powerful clients (utilities and IPPs with ever increasing pipelines). Of course, integrators will seek to differentiate with innovative products and additional solutions – and will try to become more vertically integrated.

The top seven players of 2021 accounting for around two thirds of the integrated capacity in 2021 (compared

to around 30% between 2016 and 2019) is a clear indication of an ongoing market consolidation. Nevertheless, due to the dynamic growth described here, new players keep trying to establish themselves in the market to get their piece of the pie. To secure their position, the established businesses are expanding their product portfolios. While a couple of years ago the physical system integration was their focus, most people – in addition to offering energy management system (EMS) software which has become almost a market standard – provide battery management system (BMS) software, and some even offer energy trading software.

Also, O&M services and engineering, procurement and construction (EPC) now belong to the standard portfolio.

This is necessary, as these players are being squeezed by the suppliers, not only with respect to pricing and minimum purchase quantities, but also because of the suppliers’ ambitions to increase their upstream activities. Additionally, there is also downstream integration by solar and battery project developers enhancing their system integration capabilities to source directly from component suppliers, i.e., to skip the middlemen.

Battery analytics is increasingly recognised as the key to more market traction and higher profitability. Improving transparency into the projects for which they still have ongoing warranty obligations or to driving the service offering towards the storage owners and operators enables users to differentiate from competition.

Finally, a word from the software provider’s perspective: it is far easier – and cheaper for the customer – to connect to the storage and influence the data quality in an early project phase than retrofitting the solution to an existing project set-up.

This is an extract of an article from Volume 28 of PV Tech Power, our quarterly journal. You can buy individual issues digitally or in print, as well as subscribe to get every volume as soon as it comes out. PV Tech Power subscriptions are also included in some packages for our new PV Tech Premium service.

About the Author

Sebastian Becker is business development manager at TWAICE, a provider of predictive battery analytics based in Germany, enabling integrators, owners and operators of battery energy storage systems to maximise their assets’ profitability. TWAICE’s partnerships as an independent authority include working with Munich RE on insurance services and with TÜV on residual value determinations and certifications.