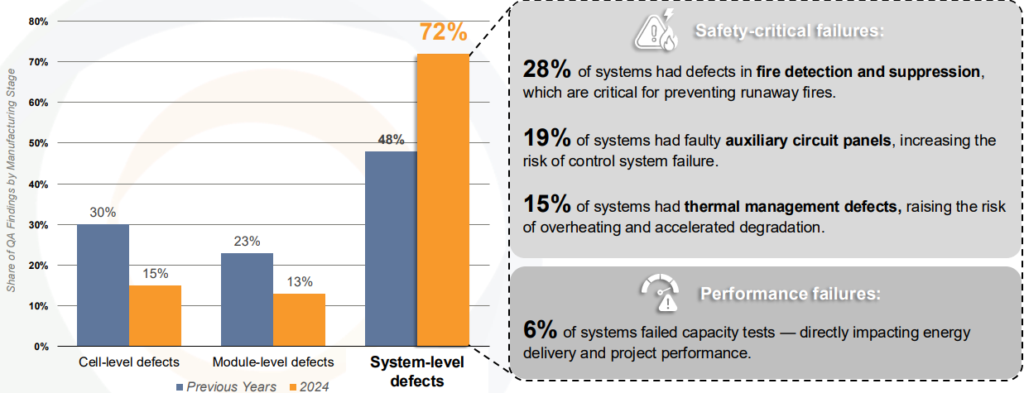

According to market intelligence firm Clean Energy Associates (CEA), 72% of battery energy storage system (BESS) manufacturing defects were at the system level.

CEA has released its BESS Quality Risks report, a summary of the most common BESS manufacturing defects from 2024.

Following system-level defects were cell-level defects at 15%, and module-level defects at 13%.

The 72% figure represents a 24% increase in system-level defects from previous years.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Of the system-level defects, 62% were identified across three ‘Safety-critical failures’. The first was 28% of defects in fire detection and suppression, 19% with faulty auxiliary circuit panels, and 15% with thermal management defects.

The other notable categorised system-level defect was ‘Performance failures,’ which comprised 6% of systems failing capacity tests.

For CEA, a critical failure denotes “Findings that may result in severe safety risks and hazardous conditions. Critical findings are likely to cause damage to other products or property, trigger non-compliance regulatory issues and generally constitute a breach of mandatory regulations.”

The firm also says that none of the inspected systems were shipped with unresolved thermal management of fire detection/suppression defects.

It follows a four-step defect resolution protocol: buyers are notified, the manufacturer is informed of the issue, the manufacturer must fix or make a new item, and then the item is re-inspected.

CEA further clarified that most system-level findings, 64%, were balance of system (BOS)-related.

Balance of system-related findings occur when defects with BESS components or improper system integration procedures arise. CEA says an example would be a live conductor exposed within the AC/DC distribution, or malfunctioning sensors and alarms due to miswiring.

30% of system-level findings were enclosure-related. These are defects from the enclosure manufacturing and mishandling during transportation. CEA gave the example of grounding mechanism defects.

6% of system-level findings are performance test-related. This includes a wide variety of manufacturing defects or improper system integration. CEA gave an example of charging/discharging failure due to wiring issues in battery rack’s high-voltage boxes.

Defects at the system level greatly affect safety, potentially causing fires, system failures, or energy shortages.

The report from CEA indicates that 28% of the inspected BESS units exhibited defects in their fire suppression systems.

These defects included non-responding release actuators for the fire extinguishing agent, non-functional fire alarm abort buttons and non-responding smoke and temperature sensors.

15% of the inspected BESS had thermal management defects. These included circulation system component failures and compressor mainboards short-circuiting.

Fire safety remains a primary focus in the energy storage sector. Recently, UL Solutions revised its fire safety testing procedures for battery storage to align with updates to the UL9540A test method.

In February, Aaron Marks, market intelligence consultant at CEA, wrote for Energy-Storage.news about the possible impacts of fires like the one at Moss Landing Energy Storage Facility on future BESS projects and public perceptions.