AMTE Power, a UK-based manufacturer of batteries, has said its new sodium-ion cells are close to being ready to send out into the field for testing and validation by select customers.

The company makes battery cells aimed at higher value market segments such as high-performance vehicles from an existing site in Scotland but is currently developing a new factory with 0.5GWh annual production capacity.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Due to it focusing on higher value cells for demanding applications, the company believes production lines at its planned ‘Megafactory’ can be as profitable if not more so than the dozens of much bigger gigawatt-hour scale ‘gigafactories’ producing battery cells around the world.

The factory in Dundee, eastern Scotland, could see revenues of about £200 million (US$235.6 million) from the 8 million cells it is projected to churn out each year, AMTE Power claimed.

Meanwhile, although the company’s main focus is expected to be on the automotive market, it is also targeting stationary energy storage systems too and has been developing its sodium-based cell with a view to commercialising it for battery energy storage system (BESS) customers.

AMTE Power’s ‘Ultra Safe’ sodium-ion cell development is nearing completion, the company said yesterday in a trading update. AMTE’s development team have achieved a targeted 140Wh/kg energy density specification.

Production is expected to begin later this year at the company’s existing manufacturing facility, with cells to be sent to customers for initial evaluation as well as project and supply validation.

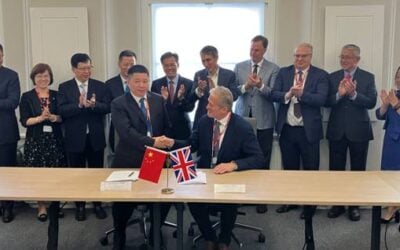

AMTE has signed one offtake deal for 1,000 cells to be used by UK manufacturer AceOn in a portable energy storage device, but the company anticipates more deals will be signed as the Dundee factory’s final investment decision nears.

AMTE believes the technology could be appealing for stationary storage at all scales, from home energy storage brands to grid-scale storage manufacturers and integrators. US-based BESS system integrators Fluence and Powin Energy have both said they will be testing and trying out sodium-ion – among other technologies – at their respective new testing facilities.

Big players, startups alike eye promise of sodium-ion, and other technologies

AMTE is by no means alone in identifying sodium-ion as a possible alternative to lithium-ion for stationary applications.

China’s CATL is among the biggest names bullish on the technology’s potential, and another UK company developing sodium cells, startup Faradion, has been acquired by Indian conglomerate Reliance Industries’ solar energy subsidiary.

In the US, manufacturer Natron Energy has been working on sodium batteries for a decade, becoming the first to go through UL 9540A fire testing with its devices and recently said it plans to open a factory in Michigan. In northern Europe, Swedish manufacturer Altris said it will open a 1,800 square metre production facility early next year. Energy-Storage.news reported on both of those companies’ plans in May.

Sodium-ion cells are promising in that they use a combination of cheap and abundant materials, without copper or cobalt which can be expensive and problematic to source from a sustainability perspective. They would also allow the BESS supply chain to be decoupled from the lithium-ion supply chain which has seen volatility and price spikes in the last couple of years, as well as a shortage of everything from raw materials to finished product.

They offer less energy density than most types of lithium-ion, which largely rules them out of automotive applications, but this matters much less for stationary storage.

The fact that it doesn’t appeal to automakers might be one of the technology’s strongest suits. At the moment, many of the delays and supply chain constraints experienced by the energy storage industry are largely influenced by the fact that BESS and EV sectors are competing for battery cell supply.

Other potential advantages include the ability to store and transport sodium cells discharged to zero volts, lowering the risk of thermal runaway. Faradion claimed that its sodium battery has 92% round-trip efficiency, broadly putting it on a par with lithium.

Many commentators have said it is likely there will be multiple different electrochemical energy storage technologies that compete with, or complement, lithium-ion in the coming years. Some of those, such as flow batteries, have been widely covered as they have been pushed towards commercialisation for some time, but other newer alternatives include Enervenue’s nickel-hydrogen battery and a number of companies also trying to commercialise potassium-ion batteries.

In a recent interview with this site, potassium-ion startup Group1 CEO Alex Girau said that lithium iron phosphate (LFP) batteries represent the benchmark in performance and cost to try to equal or beat.