Helena Li, Trina Solar executive president, discusses how the major solar PV company is growing its footprint in the battery energy storage system (BESS) industry.

There are several reasons why some companies become leaders in their chosen industry, but one of the main reasons is trust, especially in the renewable energy industry.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Customers have to trust that quality has not been compromised for cost and that their vendor or service provider will be there for them when needed.

Trina Solar is undoubtedly one of the global solar PV industry’s leaders, establishing a presence in 160 different countries since its founding in 1997, making cumulative shipments of more than 150GW of PV modules in that time by the end of the first half of 2023. The company has been labelled a member of the elite Solar Module Super League (SMSL) by PV Tech, among just a handful of other leading players.

Trina Storage meanwhile officially launched only a couple of years ago, but it has been a while in the making, according to Helena Li, Trina Solar’s Executive president. Preparing to put out a mass market offering for battery energy storage system (BESS) technologies that can be as trusted as Trina Solar is in the PV market, takes time.

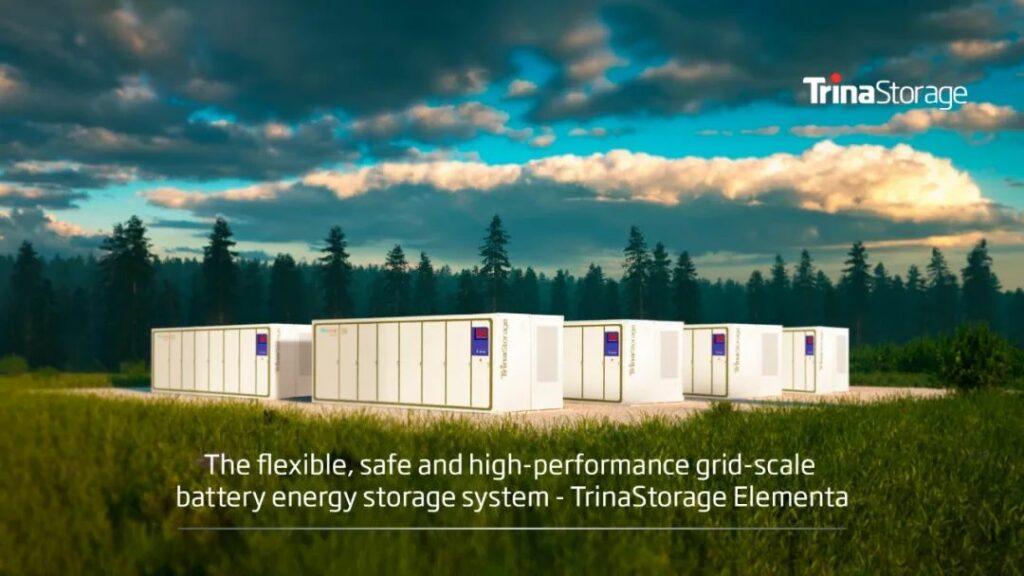

It has also been a question of getting the right go-to-market strategy. Just as Trina Solar is known for its vertical integration in everything from materials processing to cells and modules and even solar trackers, Trina Storage makes its own battery cells, which equip products like the Elementa series for grid-scale battery applications.

The second generation Elementa 2 containerised BESS solution is here. It features Trina’s own 306Ah lithium iron phosphate (LFP) cell which has an expected lifetime of 12,000 cycles, and a highly integrated design that reduces footprint, intelligent management of its liquid cooling system and rack-level battery management. Elementa 2 packs up to 4MWh of storage capacity into a standard 20ft container.

“Storage-wise, Trina actually goes back to 2015-16, when we started to look at storage. We did some very small projects, like a commercial and industrial (C&I) project in the Maldives, across 27 different islands, and gained some understanding,” Helena Li says.

“In the last three years, we started to in really invest in cell making because we realised with all the solar being deployed in the world, now is definitely a time for energy storage.”

Scale

Of course, one of the other competitive differentiators in the solar industry is the ability to mass produce quality products at scale, and few companies are as comfortable doing that as Trina.

From investing in cell production from an R&D perspective just a short time ago, the company has already ramped up to 12GWh of total ESS capacity by the end of this year.

Next year Trina Storage will “easily” get to more than 25GWh annual production capacity, Li says. Getting control of the cell, means understanding the full behaviour of the system, and understanding what customers want, from a fundamental perspective.

With cells also representing around 50% of the cost of an energy storage system, having visibility and control over cell production means Trina can continue its tradition of “making great product sustainably, and to manage the cost”, Helena Li says.

Trina has been using third-party cells integrated into its Elementa BESS cabinets, but the ability to integrate its own cells will allow the company to respond directly to what their customers really want.

And learning what customers want is of course, again, fundamental to establishing a leadership position in any industry. It’s for this reason that Trina Storage has served as system integrator on some of its own BESS projects, just as Trina Solar has done for PV.

“Cell technology, that’s definitely going to be a competitive differentiator in the future. That’s why we are going for integrating cell-to-cabinet production.”

Having involvement in system integration at project sites meanwhile gives Trina Storage “first-hand information on where the market is, what the customer needs, what are the trends,” Li says, although she is keen to emphasise that Trina isn’t trying to become a big player in system integration, but that first-hand experience helps it understand what its customers, many of which will themselves be system integrators, need.

Helena Li says this success will be followed by growing traction in other markets. While she can’t disclose just yet due to customer confidentiality, deal announcements in the US are imminent, and other regions such as Southeast Asia and parts of Latin America, as well as growing C&I opportunities in China and Japan are also interesting for Trina Storage.

That said, the US is a really fast-growing market for storage and Li says Trina’s in-house analysts believe even the bullish forecasts coming from various research firms are too conservative in their estimates, in some cases by as much as 50% in their assessment of market size.

That’s largely to do with incentive programmes committed to in the Inflation Reduction Act (IRA). With the act, and other key legislation like the Bipartisan Infrastructure Law, the US has become “very, very aggressive” in its promotion of renewables, Helena Li says, but also in its promotion of locally-based manufacturing of clean energy technologies.

Trina could play a role in helping build the supply chain, working with local partners.

Again, it’s all about trust. The fact that Trina’s customers can count on a 26-year track record means that many of its big solar customers are now enquiring about Trina Storage BESS for their projects, Li says, and this aspect of ‘horizontal’ integration means Trina is the only big league solar PV player that can offer PV modules, solar trackers and BESS.

In an increasingly competitive market, Trina always tries to have “the best quality controlled, mass production skill set,” Helena Li says.

“Because the customer is the most important thing to us. It’s the trust between us and our customers that gives us our competitive edge.”