It’s been all systems go for Fluence this year it seems. Even at the height of the COVID-19 global shutdown, we heard from chief operating officer John Zahurancik how the technology provider was able to get its battery storage and its workers onsite to deploy them with the aid of carefully taken precautions.

More recently, the AES-Siemens joint venture (JV) company announced the arrival of its sixth generation of ESS technology solutions and newly-incoming company CEO Manuel Perez-Dubuc was quoted as saying that Fluence saw this range of three market-segment specific products, built on the same modular platform, as having the potential to create a market inflection point in the clean energy transition all over the world.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

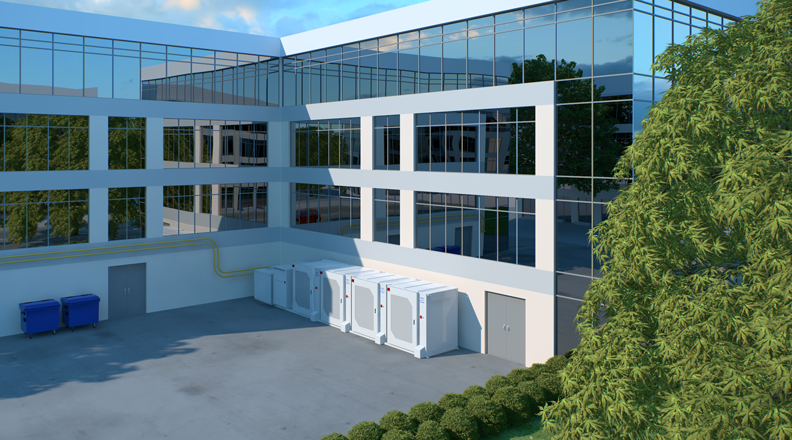

The Gridstack, Sunstack and Edgestack products aim at the front-of-meter utility market, the DC-coupled solar-plus-storage market and the edge of grid commercial market respectively. Their launch comes at a time of crossroads for the industry, with rival Powin Energy also launching its latest range earlier this year and claiming large pipeline numbers and another rival, NEC Corporation’s Energy Solutions division, bowing out of the industry over the course of what seemed like a few short days.

While Fluence’s claimed pipeline of 800MW / 2,300MWh of the new systems already ordered by customers sounds – and is – impressive, Fluence VP for marketing and strategy, Brian Perusse, tells Energy-Storage.news that this is “the level of entry that you need to play in the next phase” of the market.

“There’s significant investment in people, technology and capability and scale,” Perusse says.

“As we saw with wind and solar, there’s consolidation and there’s a lot of requirements to play at the next level. Our view is that that is happening and we envision that will continue to play out to serve this next phase of the market, it’s part of the maturity of any market.”

‘What is mass customisation?’

Energy-Storage.news noted that the claimed pipeline is more than 10x what the entire US deployed in Q1 2020, while Perusse says that in the 10 years leading up to the creation of Fluence, the AES and Siemens energy storage teams collectively installed 485MW. Nearly doubling that decade-long track record in sixth months “says a lot about the capability of the technology” and how it is becoming recognised as a toolkit of the energy system in more and more parts of the world.

From the early “first phase” of the modern ESS industry, which could be considered to have begun in 2007-2008, and was about proving the technology works and can be of economic and environmental benefit, there were “small projects in a number of places,” Perusse says. The phase that followed put “a large number of projects in a few places”.

“This next phase we’ve entered is a large number of projects in a lot of places.”

As well as those orders already booked, Fluence is apparently also now receiving enquiries and interest for at least a hundred megawatts of storage projects in each of around 10 different countries. From virtual transmission lines to large-scale solar-storage to ancillary services and everything in-between, this meant that the new products are aimed to be customisable for each customer’s needs but also modular and able to be replicated at scale and factory-assembled.

“A customer in Australia has a different need than a customer in the UK. While it sounds simple, they both need energy storage, they actually have software changes, they have optimisations on the hardware, they have to understand battery performance degradation, life tradeoffs between use – so there’s a lot of tailoring that happens for those projects.

“So we’ve invested a lot of time and energy trying to figure out: what is mass customisation? How do you get the benefits of mass production, in the factory assembly, in the factory testing, ship it to site, but also maintain that customisation that’s required for the different types of projects? That’s essentially what this new technology does – it brings the benefits of that mass scale and customisation into the single platform that we haven’t been able to do before and no one has out there yet today.”

Flexibility for functionality and to leverage supply chain

All three system types are based on the same building block, the Fluence Cube. Around 9ft to 10ft in dimensions, Brian Perusse says this allows the company to configure customer systems for both power and energy applications. The same Cube design could have one hour, 4+ hours or 6+ hours of energy storage duration, using different battery modules, different hardware and design. The core Cube doesn’t change, but the internal racking design, the cooling systems, different components and balance of system elements “that allow for the optimisation between these things,” can be customised.

The flexibility this allows works on several levels, Fluence claims. One is that the stability of the Cubes – each is roughly 800kWh of capacity – means that transportation logistics and costs are streamlined.

“The design is both for operations but also transportation and delivery we find that a lot of the costs left in systems are the softer costs. Everyone focuses on the hardware of the batteries as the cost.

“[As the cost of] solar was going down, everyone focused on the PV modules until they realise there were a lot of other costs that drive the entire cost of ownership, so that’s the approach we’re taking: how to drive the costs out of everything else,” Perusse says, and shipping and getting a product to site is a soft cost many often don’t consider.

Another aspect of flexibility is that the provider is not tied to one type – or one supplier – of batteries. The stacked systems can be built with different chemistries including nickel manganese cobalt (NMC) or lithium iron phosphate (LFP) depending on the customer requirements. Both types will have a role to play in the market, the company believes and the design reflects that. Not being tied to a vertically-integrated supply chain can have other benefits, Brian Perusse says, and this extends beyond the battery component.

“One of the core elements we have always prided ourselves on is leveraging the supply chain and leveraging overall capabilities from third parties. So instead of vertically integrating, we purposely design to leverage the supply chain, so we can have access to what’s becoming terawatt-hours of battery capacity in the market.

“We have the same approach for software, same approach for inverters that allows us to keep three to four major suppliers instead of vertically integrating.”

Cover Image: Artist impression of a Fluence Gridstck project a transmission substation. Image: Fluence.