In a double-whammy of NMC battery news, SolarEdge has started shipping cells from its new South Korea gigafactory while Leclanché has claimed a breakthrough in environmentally-friendly cell production.

California and Israel-based smart energy management tech firm SolarEdge has started shipping new nickel manganese cobalt (NMC) lithium-ion battery cells for stationary energy storage from its new manufacturing facility in South Korea, Sella 2.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

On the same day as SolarEdge’s announcement (17 January), Swiss-based battery cell manufacturer and ESS integrator Leclanché announced it had made a breakthrough in environmentally-friendly production of its ‘high-performance’ NMC battery cells.

SolarEdge’s new NMC gigafactory

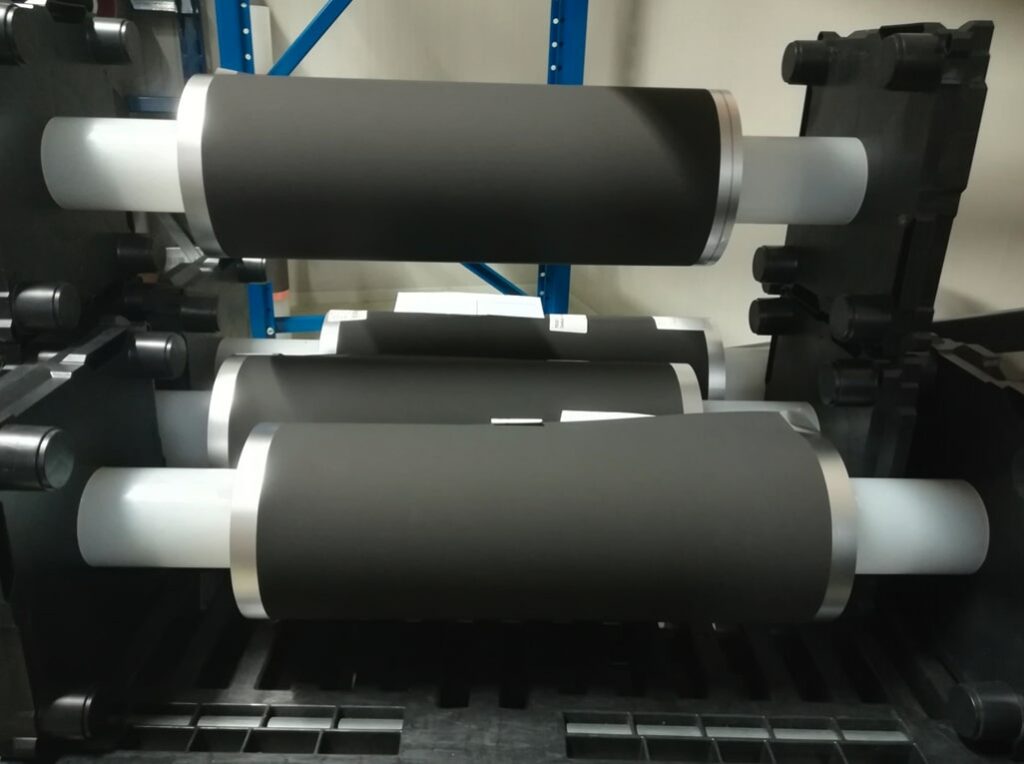

SolarEdge’s in Chungcheongbuk-do Province began producing test cells in May last year, reported by Energy-Storage.news at the time, and will have a 2GWh annual production capacity when fully ramped up.

The cells are optimised for energy storage system (ESS) applications, with a high cycle life (up to 8,000 cycles), high energy density and power throughput and a wide temperature range.

SolarEdge said the NMC cells have been optimised for all ESS segments, although last year a spokesperson told this site that they would primarily be aimed at the fast growing residential sector. SolarEdge has its own product for that space, the SolarEdge Energy Bank Home Battery, which is manufactured in Europe.

The new manufacturing facility from SolarEdge was made possible by the acquisition of South Korea-based battery manufacturer and ESS integrator Kokam in 2019, with the two companies building the site together.

Leclanche claims breakthrough in environmentally friendly production

Swiss-based Leclanché said it has been able to reduce the cobalt content in its G/NMCA cells from 20% to 5% and manufacture its electrodes using an environmentally friendly water-based process. This allows it to completely dispense of the use of highly toxic organic solvents called NMPs which are typically common in conventional processes, it said.

Furthermore, it claimed the new G/NMCA cells have an energy density that is 20% higher compared to conventional G/NMC cells.

“With the water-based production of the high-capacity NMCA cathodes, we have reached a decisive milestone in lithium-ion technology,” said Dr Hilmi Buqa, Vice President R&D at Leclanché. “Until now, producing them using environmentally friendly processes was considered impossible. But, now we have mastered the process.”

The company recently changed CEO after eight years with Anil Srivastava stepping down after eight years, succeeded by CTO Pierre Blanc.