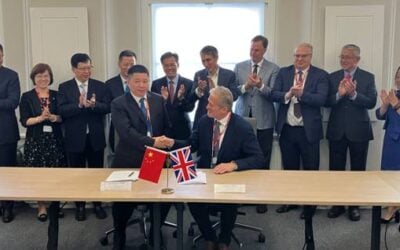

Saft has opened its third manufacturing site for energy storage systems (ESS) in Zuhai, China, adding to two existing “strategic hub” facilities in Bordeaux, France and in Jacksonville in the US.

The company offers utility-scale, microgrid and commercial and industrial (C&I) ESS solutions to serve grid services and energy applications. This includes its most recently launched 20-foot containerised ESS product, Intensium Max High Energy, which comes with 1.2MW rated output and 2.5MWh of storage capacity.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The new factory will solely focus on the assembly of ESS containers, and will have the capability of producing 200 containers per year, which the company said in a press release is equivalent to 480MWh capacity. The plant in Zuhai is already producing Intensium Max High Energy units.

While the 100-year-old company serves customers in markets ranging from aerospace and defence to medical, telecoms, transport and more, within the ESS segment Saft “has grown from being a mere battery supplier, to a fully integrated energy storage and microgrid technology solutions partner,” Saft CEO Ghislain Lescuyer said in a short video sent to press including Energy-Storage.news.

“Our ESS business is growing fast. We have installed more ESS capacity in the past 18 months than in the 10 years before that. We need to have a global presence in ESS in order to serve our customers, no matter where they are,” Lescuyer said.

“This new hub will allow us to be even more reactive to customers’ needs, with more speed and efficiency.”

Saft’s shareholder is the French oil & gas major Total. Lescuyer said the parent company has the ambition to become a “world leader in renewables,” while also reaching net zero carbon emissions by 2050. Recently completed projects Saft has supplied include the Agnew Gold Mine project in Australia, where battery storage has enabled a remotely sited industrial operation to be 50% to 60% renewables powered.

“Renewable energy is intermittent by its very nature. So, you need storage solutions to ensure a stable and flexible power supply,” Lescuyer said.

The company claimed that it will be able to minimise its customers’ total cost of ownership of energy storage systems, through an integrated approach that encompasses everything from starting concept and sizing of projects to engineering, delivery and grid connection.

Investing in a plant in China to add to the existing plants in the US and in Europe means that Saft’s ability to serve customers all over the world and participate in the transition to renewable energy will be “enhanced,” the company said.

Energy-Storage.news hosted a webinar with Saft earlier this year: ‘How to keep your energy storage system flexible in times of changing market conditions’. In that webinar, alongside company technical experts and a system end-user, Saft director for innovations and solutions for energy Michael Lippert explained various aspects of the company’s strategies, such as how ESS solutions need to be able to respond to different applications in a “permanently evolving market landscape” and what lies behind the selection of battery chemistries.