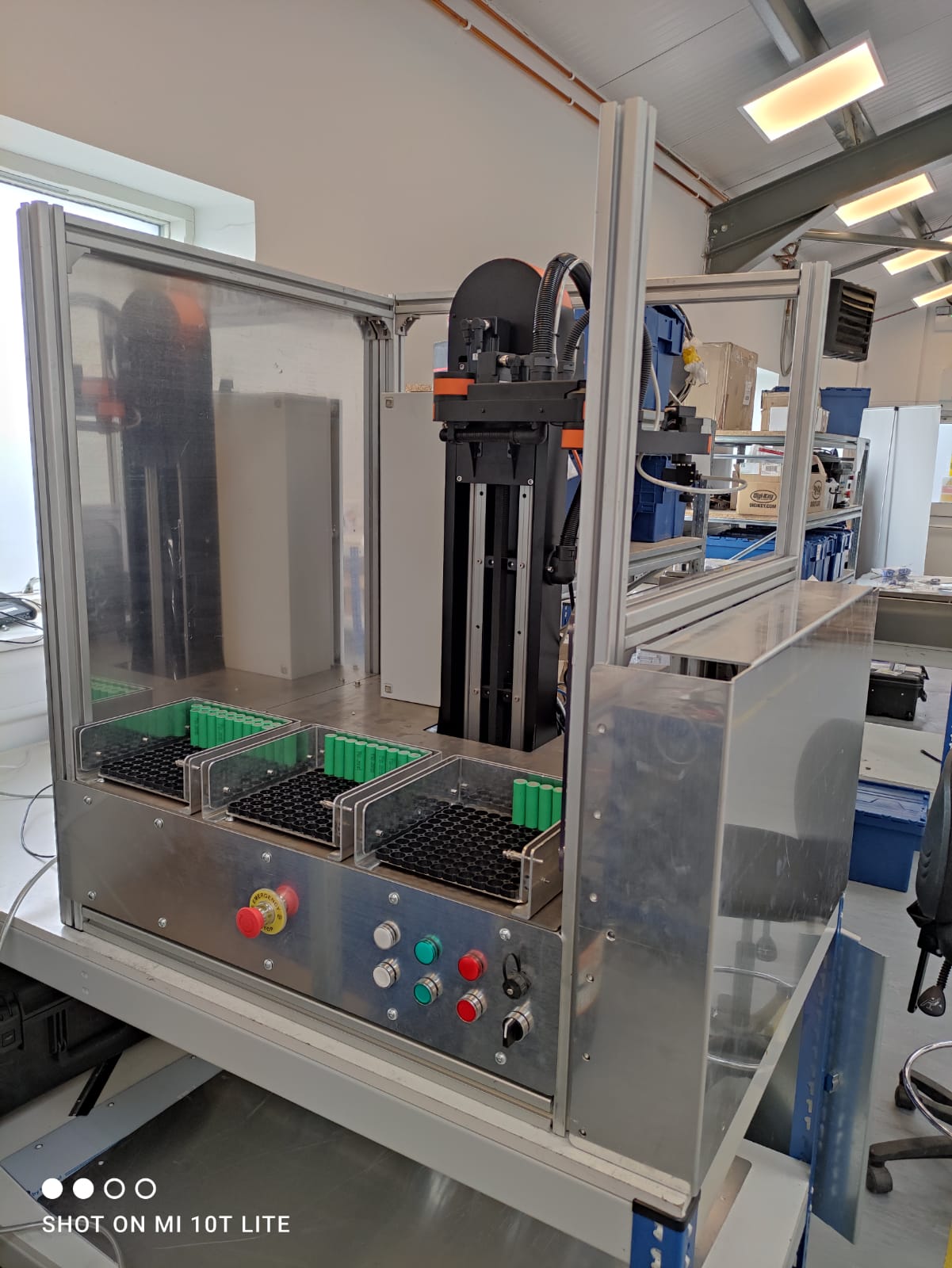

A prototype system that can test and sort used battery cells for second life applications has been developed by four companies in the UK in a government-funded initiative.

The system, pictured above, relies on a combination of robotics, software and automation to detect the health of individual cells taken from end-of-life battery projects like EVs.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The project has been underway since May 2021 and was part-funded by Innovate UK, the UK’s innovation agency. It involved four companies and organisations including Aceleron, the battery energy storage system solution company which designs its systems to be easy to disassemble and re-purpose.

Other participants include Innvotek, a specialist in the automation of inspection, maintenance and the digitisation of processes; MEV, an ultrasonics specialist company providing equipment and expertise in operating systems and bespoke application software; and the Brunel Innovation Centre, part of Brunel University.

The companies said the prototype has the potential to significantly reduce the unnecessary waste of the raw materials used to build batteries.

Carlton Cummins, Aceleron’s CTO and co-founder said that at the end-of-life point, half of the battery cells in an EV battery will typically still have a state of health higher than 80% which could give them a lifetime of a decade or more in the stationary energy storage sector.

Second life solutions company Connected Energy’s CEO Matthew Lumsden, who Energy-Storage.news recently interviewed, says that a 25% degraded battery is still good for ten years of energy storage.

Cummins added: “As we increasingly turn to electricity to power our lives, the issue of battery waste is of serious concern and this new system has the potential to preserve cells that would otherwise have been discarded. With Lithium shortages being forecast as soon as 2035, this machine has enormous potential to preserve what is left – and ensure that we maximise the use of the raw materials used to make battery products.”

The issue of waste in the lithium-ion battery sector has come to the fore in recent years as the number of cells in use grows exponentially with the rise in EVs and energy storage. In a guest feature for Energy-Storage.news in June, Piotr Grudzień, innovation consultant at Bax & Company, proposed a four-step plan to improve the efficiency of battery reverse logistics in Europe. The US just launched a US$335 million battery recycling programme.

EV groups are increasingly tying up with second life energy storage solution companies to repurpose their batteries for storage, but the scale and universality of these are small relative to the size of the market.

A major challenge in designing storage systems using pre-used batteries is the potential lack of uniformity of design, degradation and use case history amongst constituent battery cells. Lumsden said his company’s ‘secret sauce’ was a sophisticated battery management system (BMS) that could communicate across these parameters, but ensuring storage units are as uniform as possible to start with will also be integral to ensuring systems perform.