Energy storage is a compelling complement to wind and solar, because of high flexibility and ability to operate as both load, when it charges, and generation, when the energy is deployed. Energy storage addresses many of the challenges to grid operators providing safe and reliable electricity for customers, and due to rapidly declining costs, performance improvements of lithium-ion batteries and an emergence of “grid-ready” energy storage products, commercially viable grid energy storage has now arrived, in certain applications. As energy storage becomes more widely available and economically feasible, it may make renewable generation, when paired with energy storage, a more viable option to provide reliable electric generation – and load demand – service in more areas of the world.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Storage anywhere

Energy storage can be deployed everywhere in the power grid, connected to transmission (T), distribution (D), or on customer-side of the meter. Storage may be co-located with renewables, conventional generation, loads, or it may be standalone.

Energy storage connected to the end customer could potentially address services upstream to support distribution, transmission, and generation functions, because its dispatch also propagates upstream. In contrast, a transmission-connected system typically cannot provide downstream services. Larger systems take advantage of economies of scale, which may offset access limitations for certain value streams.

Is that cycle worth it?

Service stacking comes with the costs and complications of multiple, potentially competing, commitments, which may also increase the wear and tear on energy storage systems. When designing an energy storage project, it is important to understand the value and associated requirements for each service addressed. Energy storage is still a relatively expensive resource, so excessive sizing or operation without an associated payback may cause a potential project to become uneconomic.

A common and desirable use of energy storage is often called peak shaving i.e. reducing the amount of power drawn from the grid beyond a specified limit. This typically maps to more precise services, such as resource adequacy (i.e. peaker plant substitution) or transmission or distribution upgrade deferral (i.e. non-wires alternatives). The sizing, availability, and location of energy storage for these services is critical, but the required dispatch may be infrequent when the grid is under stress, to achieve the desired benefit of deferring or avoiding an alternative major capital investment.

Other services, such as spinning and non-spinning reserves, may also be desirable with energy storage with very low operating costs because they essentially require energy storage to act as a reserve with no dispatch. Energy storage may also be able to offer these services while charging, by committing to stop charging if needed.

Frequency regulation, the instantaneous balancing of grid supply and demand, is more nuanced. On one hand, battery storage can change its dispatch almost instantaneously to match grid imbalances, unlike conventional generators which have significant inertia. However, the continuous charge/discharge cycles associated with frequency regulation stress the most commonly deployed battery technology, lithium-ion. While participation in the frequency regulation markets may be initially lucrative, this should be balanced against loss of capacity, efficiency, and premature replacement of battery modules in these projects.

Energy time-shifting, sometimes called arbitrage, is another nuanced service. While buying (or charging) energy at low prices and selling (or discharging) at high prices sounds like a good idea, the spread in price must overcome roundtrip efficiency losses and the degradation of potential battery deep-cycling.

The valuation of energy storage projects can be a complicated and location-specific matter. Due to the limited energy in an energy storage device, modelling the state-of-charge over time is essential to understand which services may be stacked together into a viable business case. To support this type of modelling and simulation, EPRI, with support of a California Energy Commission grant, developed and released the publicly-available Storage Value Estimation Tool (StorageVET: www.storagevet.com).

Industry approaches to manage battery storage degradation

Battery storage degradation typically manifests as a loss of energy retention capacity, reduction in power delivery capability and efficiency, and eventually need for replacement of batteries. Depending on the state of a battery system, replacement might imply only the change of few worn out modules or a total replacement.

Battery storage suppliers sometimes provide lifetime guarantees under assumed operating conditions or an assumed service dispatch. For example, they may guarantee a 10-year life if the battery system is cycled only one time per day at full depth. This can be limiting in cases where the energy storage system changes over time as the needs of the installation change, which is probable over a 10-20 year project life. Other developers provide more sophisticated information, which may assess “equivalent cycles” that the battery system can undergo before requiring replacement.

One degradation management approach applied by industry is to oversize the physical capacity of the system, while maintaining the nameplate capacity constant. This approach allows battery systems to deliver to expectations of the customer for a longer period of time by keeping the degradation hidden. As a drawback, this approach increases the upfront cost of equipment. Other approaches may include the addition of battery storage capacity over time as the system degrades, which may offer additional flexibility to assess project needs over time, while taking advantage of future, assumed cost reductions in the future.

Factors influencing battery storage degradation

Lithium-ion batteries represent the vast majority of current energy storage deployments. Between 2013 and 2018, it represents 94% of the deployed capacity of battery storage in the US [1]. It should be noted that there are other storage technologies not covered here, which may have different degradation drivers. Additionally, lithium-ion batteries are a diverse class with a number of different chemistries and formats; this section aims to provide indicative descriptions and does not attempt to explore all these nuances.

Degradation of lithium-ion batteries is impacted by several variables. Known drivers of degradation include: temperature of operation, average state of charge over its lifetime, and depth of charge-discharge cycles. Educated management of degradation is instrumental for economic planning and operation of energy storage projects, as well as any warranties or performance guarantees that may be provided by the equipment suppliers.

The first driver of battery storage degradation is related to time at average state of charge, which is separate from cycling. Empirical data has shown that lithium-ion batteries at rest lose energy retention capacity depending on the temperature and the state of charge at which they are stored [2].

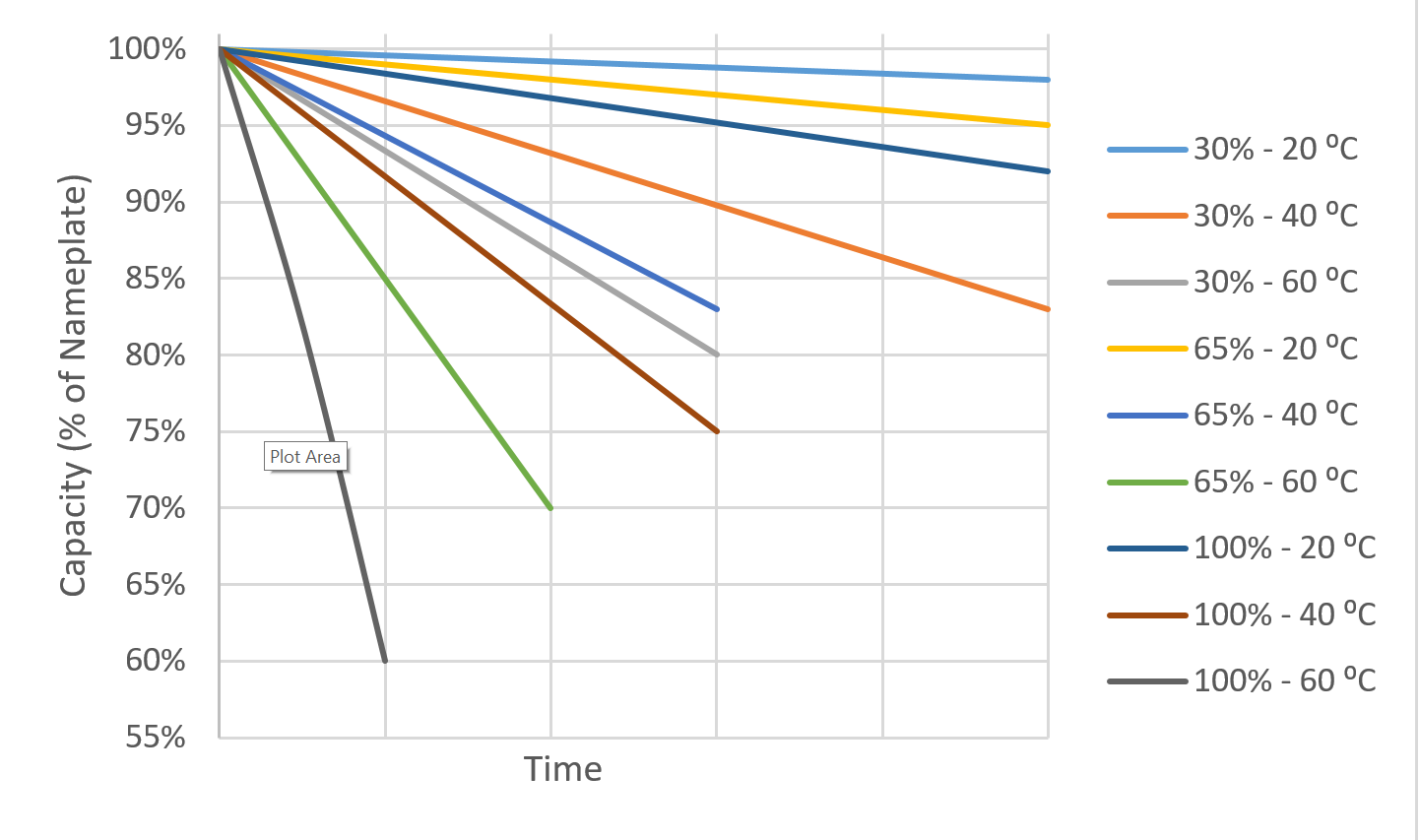

Figure 2. Capacity degradation of lithium-ion batteries for different combinations of average state-of-charge and temperature. For example, the green plot shows the degradation of a battery operating at 65% State of Charge and 60 °C

Figure 2 illustrates that energy retention capacity degrades faster at elevated temperatures, if the state of charge is higher. Considering these degradation drivers is beneficial for ageing prediction during the planning process. In operation, lithium-ion battery storage systems may extend life through effective thermal management and by avoiding long durations at high state of charge. However, this needs to be weighed against the potential efficiency effects of active thermal management, as well as the potential for energy storage to be called for unexpected dispatch. Forecasting of needs and energy storage control approaches are particularly important to manage these trade-offs.

Charge and discharge cycling of lithium-ion battery storage is another important source of degradation. Deeper cycles affect lithium-ion battery degradation more than shallow ones.

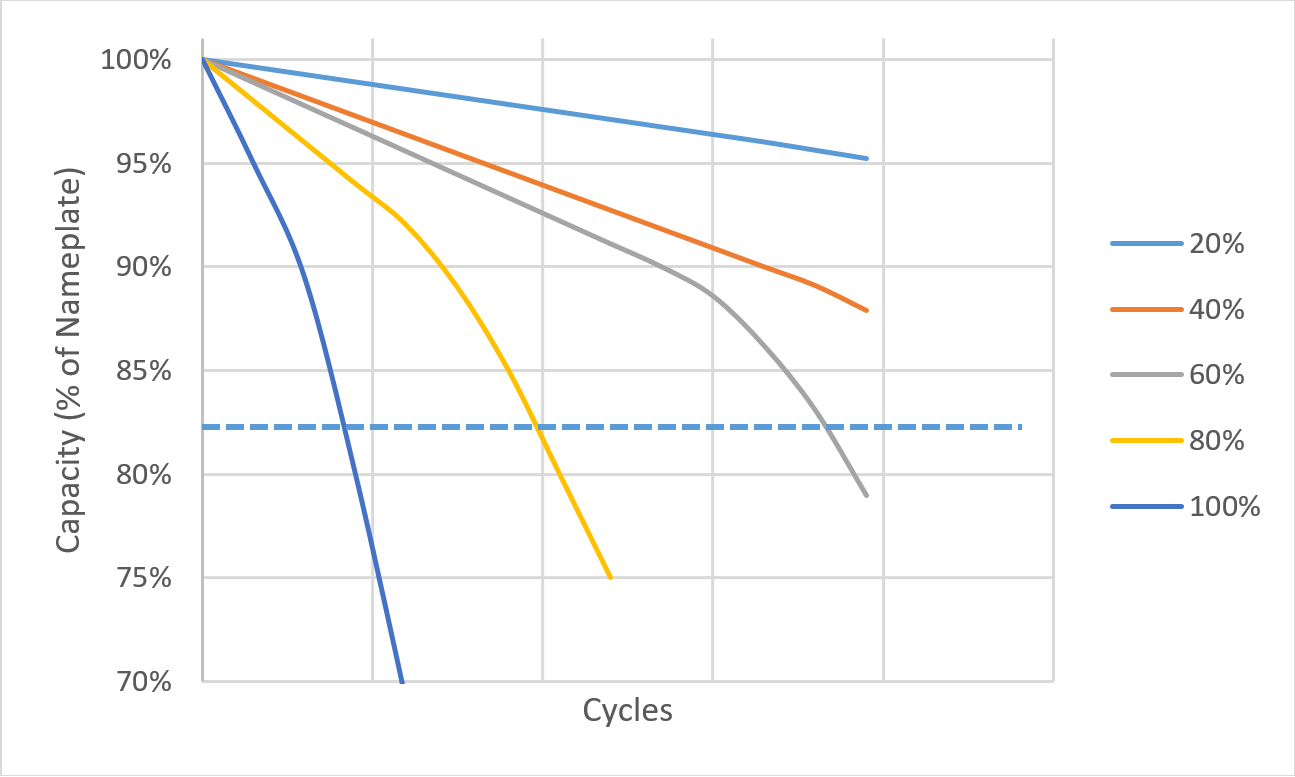

Figure 3. Capacity retention degradation impacts of cycling depth-of-discharge

Figure 3 illustrates this relationship. Additionally, some batteries have a characteristic of accelerating degradation later in life, as shown by the “knee” shape in Figure 3.

Understanding and modelling the relationship between operation and degradation facilitates optimised planning of energy storage projects, by improving the accuracy of prediction of success or failure. It also improves the operation by allowing the design of dispatch strategies that take into account the cost of cycling-related degradation.

Modelling degradation in energy storage project economics

EPRI’s StorageVET® may be used to understand how an energy storage project may be designed and dispatched to maximise project lifecycle value. The tool uses optimisation-based modelling to simulate the operation – dispatch and capacity reservations – of the storage system offering one or more grid services, while keeping track of aspects like degradation and grid service compatibility. It can represent different levels of relative value of grid objectives with respect to charging/discharging activity, to find how more aggressive activity might lead to higher revenue, but also higher replacement costs, ultimately helping find the most effective trade-off [3].

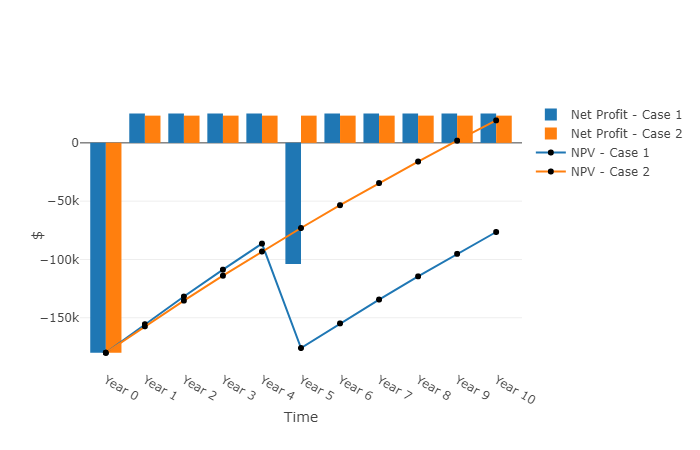

A simple example to understand the trade-off between value of operation and cost of degradation is provided. We model a battery system performing energy time-shift (arbitrage). The following Net Present Value table corresponds to the system when it performs two cycles of full charge/discharge every day for 10 years, during the most profitable times of each day. At the end of the sixth year, it requires a replacement.

The same project is modelled again, but this time performing only one cycle of full charge/discharge each day, during the most profitable hours. This scenario yielded a lower revenue due to energy time-shift, but this is outweighed in impact by the reduced cost of avoiding a battery replacement altogether during the 10-year project life.

Figure 4. Cash flow of two projects. Represented in blue follows a more aggressive strategy that ignores degradation but obtains more revenue. Orange follows a more conservative strategy that leads to less degradation.

Using a tool like StorageVET® or similar optimisation software, the user may test different “penalty functions” for energy storage cycling, essentially guiding the optimisation to require larger minimum price spreads for the energy storage system to cycle. Because the impacts of degradation often become evident farther in the future, it is important for system operators to recognise these general trade-offs early in projects.

Real-world energy storage project reliability

Battery storage projects are still relatively nascent in a commercial sense. As a result, the industry is still learning about the real-world sources of degradation and downtime for integrated systems.

These systems are complex with many subsystems, where many sensors, communication channels, power electronics, thermal, and computational systems work together to accommodate performance requirements. As a result, insufficiently robust integration or unanticipated events may cause failure at different points within the system.

EPRI and other entities, such as the US National Labs, are working toward the development of common testing and measurement of both lab tested and commercially fielded systems. A group of EPRI member utilities are currently working on a multi-year effort to build a common database with energy storage performance track record and learn more about the observed sources of downtime and performance in real-world energy storage projects. Building a track record of reliability for energy storage projects is critical for supporting cost-effective investment of energy storage that supports the reliability and affordability of electricity for all members of society.

References

[1] G. M. Research, “U.S. Energy Storage Monitor,” GTM, Boston, Q2, 2018.

[2] A. D. H. G. Sebastien Grolleau, “Predicting lithium-ion battery degradation for efficient design and management,” in EVS27 International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Barcelona, Spain, 2013.

[3] Electric Power Research Institute, “StorageVET® V1.0 Software User Guide: User and Technical Documentation for the Storage Value Estimation Tool,” Electric Power Research Institute, Palo Alto, CA, 2016.