In June, Sungrow took the bold step of deliberately combusting the 10MWh of its PowerTitan 1.0 liquid-cooled battery energy storage system (BESS), becoming the first company globally to conduct such a large-scale burn test. The company has subsequently invested approximately 4.23 million USD[1] to perform the world’s largest and longest burn test on 20MWh of its PowerTitan 2.0 liquid-cooled BESS.

The two tests conducted within six months of each other underscore Sungrow’s commitment to technological innovation, its pursuit of product quality and its dedication to ensuring the safety of both personnel and assets at energy storage plants.

The 20MWh burn test replicated a real-world power plant fire scenario, completed under the oversight of DNV (Det Norske Veritas) experts and over 100 clients, delivering results exceeding expectations. The results were clear: there was no fire propagation during the thermal runaway incident. In contrast to conventional industry burn tests, this test was a significant upgrade in terms of combustion duration, testing conditions and safety standards, establishing a new benchmark for safety through rigorous and extreme testing.

Challenge 1:

Withstanding over 25 hours of combustion, proving superior system protection capability

Unlike common industry-standard combustion tests of 4 to 8 hours, this challenging test was designed to last for 3 to 6 times longer. After continuous burning for 25 hours and 43 minutes, the container structure of the thermal runaway unit remained intact, and the system could still be safely hoisted for removal. Importantly, the fire did not spread beyond the unit, demonstrating the PowerTitan 2.0’s advanced explosion venting, flame retardancy and impact resistance capabilities.

Challenge 2:

Enduring temperatures high enough to melt steel, verifying thermal runaway containment

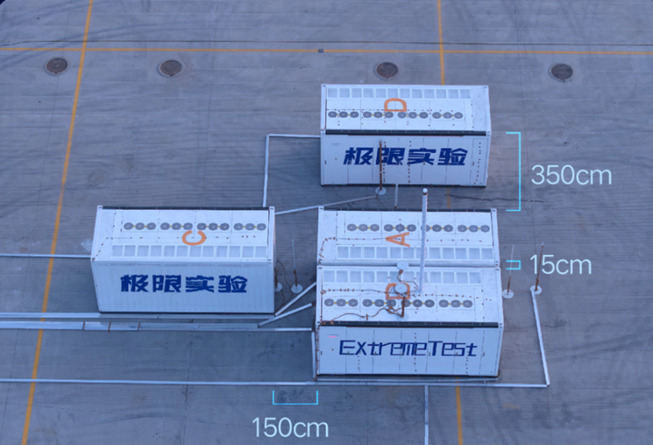

To simulate extreme operating conditions, four fully-charged energy storage units were arrayed nearby — containers A and B were only 15 cm apart, which is the absolute minimum distance permitted in the industry (most power plant containers are spaced 3 meters apart). Despite the flames from container A reaching 1,385°C — temperatures high enough to melt steel — the fire did not spread to the neighbouring container B, which maintained a safe temperature of 40°C. This result validates the PowerTitan 2.0’s superior fire insulation ability, even when the units are placed at extremely close quarters.

Challenge 3:

Testing fire resistance and flame retardancy without firefighting protection

In this phase of the test, all firefighting systems for the BESS containers were intentionally shut off, leaving the units unprotected and significantly increasing the safety risks. Despite this, the PowerTitan 2.0 performed very well, with all four storage container doors remaining intact. The fire was effectively contained within the container and damage was limited. This demonstrated the BESS’s ability to autonomously respond to extreme fire situations, highlighting a robust passive fire protection design that minimizes risk.

Safety is the cornerstone of the energy storage industry. Sungrow’s two consecutive, high-investment, extremely large-scale burn tests on the PowerTitan series reflect the company’s commitment to safeguarding personnel, assets and operations at power plants, as well as its dedication to reinforcing safety standards for the entire industry.