Solar power has never looked so good. Barely a day goes by when I don’t see a story about another multi-megawatt project vying for the title of ‘cheapest solar’. This push for renewable generation (not just solar) is a result of many factors: the Paris Agreement has played its part and the recent push by global superpowers such as China to replace coal with greener alternatives has helped to fuel the global surge in projects. A recent report by Carbon Brief has even suggested that more electricity was generated from wind turbines than coal in the UK last year, for the first time on record. But for me, the primary reason for installing renewables is simple – the financial benefits are now impossible to ignore.

Solar technology prices have dropped almost 70% in the past 5 years according to BNEF data, and it looks like these costs will continue to drop. From a levelised cost of generation perspective, solar is trending towards 5.9p/kWh (US$0.07) in the UK, which makes it one of the cheapest forms of electricity generation available today (wind generation can drop as low as 4.7p/kWh). By contrast, widely utilised CCGT generation (combined cycle gas turbine) has a levelised cost of around 6.5p/kWh by comparison and, accounting for carbon capture, coal generation can be as high as 148p/kWh.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

On and off-grid, industrial-scale storage is the key

Clearly, renewable energy is now a viable alternative to traditional generation from a cost perspective. However, in developed energy markets, like the UK, the penetration of renewables -solar and wind in particular – into our national generation mix, continues to be constrained by ageing infrastructure, high grid connection costs and its intermittent, weather-dependent nature. Cheap renewable energy must be unlocked, and large-scale, industrial energy storage is the key to firming output and balancing our network.

But let’s not forget the huge off-grid market for renewables. We have already seen examples of businesses benefitting from the combination of solar and storage, especially in sub-Saharan Africa, where the pairing is proving to be more cost effective than widespread diesel power generation. A typical mining operation in South Africa for example, could use up to 7.5m litres of diesel each year at a project cost at more than US$1/litre of fuel. With solar PV alone (no storage), it is estimated that this mine could displace approximately 40% of the diesel cost – a significant saving, but by installing storage too, this figure could rise to upwards of 90%.

Looking closer to home, but this time on the subject of future policy and regulation, we at redT welcome the UK Government and Ofgem’s recent decisions to seek outside counsel to better understand how the UK can develop a smarter, more flexible and low carbon energy system. Importantly, the future grid will incorporate much stronger price signals for balancing and with a renewable-dominated energy mix, storage will become a vital element of grid infrastructure. However, whether this is on a centralised, de-centralised, or a combination basis, is yet to be decided.

Why we don’t use the ‘B-word’

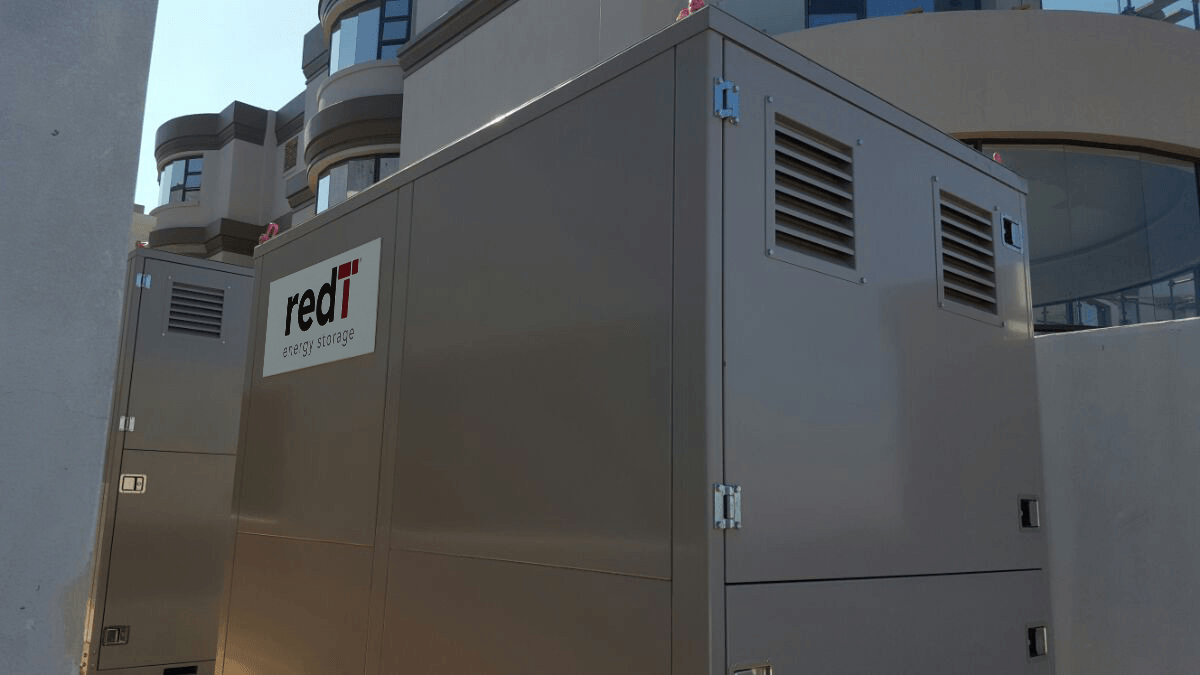

Fundamentally, the key to unlocking renewables is removing intermittency and creating ‘firm’, reliable power, which can be deployed whenever the end user requires it. Technology-wise this is an energy intensive process requiring a long duration, high capacity, industrial solution, capable of 100% depth of discharge. There are few technologies out there which are capable of doing this, however, flow batteries are ideal for this application. RedT’s energy storage machines in particular are capable of being used continuously, every day, without significant degradation and requiring only basic operating and maintenance work throughout their 20+ year asset life.

This is why we call our energy storage products ‘flow machines’, as opposed to conventional ‘batteries’. They are hard-working, industrial assets, designed specifically for high utilisation through continuous, industrial scale usage, with low project opex costs.

Personally, I think 2016 saw the energy storage market mature at a faster rate than anyone could have predicted, and 2017 looks set to be no different. I am excited to see what the next 12 months has in store and we look forward to developing our unique product offering and playing a leading role in unlocking firm, cheap renewable energy in global markets through the widespread adoption of industrial scale energy storage, hopefully including our Vanadium Redox Flow Machines.