A 10MW hydrogen production plant powered from renewable energy has just opened in Fukushima Prefecture, Japan, thought to be the world’s largest to date.

Named Fukushima Hydrogen Energy Research Field (FH2R), it’s been put into action through a consortium that includes the Japanese government’s New Energy and Industrial Technology Development Organisation (NEDO), along with private companies Toshiba Energy Systems & Solutions Corporation (Toshiba ESS), Iwatani Corporation and regional electric power company Tohoku Electric Power Co.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Under construction since 2018, the system, in Fukushima’s Namie Town, went into operation at the end of last month with an official ceremony held on Friday, 7 March to welcome its completion. FH2R produces up to 1,200 Nm3 of hydrogen per hour, helping to adjust supply and demand on the local grid and therefore help integrate variable renewable energy.

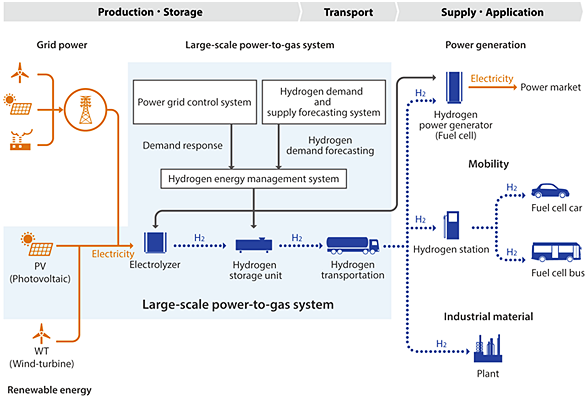

The research project is paired with 20MW of solar from a nearby solar PV farm, which powers the electrolyser that pulls hydrogen from water. A hydrogen demand and supply forecasting system will determine how much it needs to produce for supply as hydrogen for transporting away for use in both Fukushima Prefecture and taken to other regions such as the Tokyo Metropolitan Area, and conversely how much for helping balance the power grid.

“The most important challenge in the current stage of testing is to use the hydrogen energy management system to achieve the optimal combination of production and storage of hydrogen and power grid supply-demand balancing adjustments, without the use of storage batteries.

“To address this challenge, testing will begin to identify the optimal operation control technology that combines power grid demand response with hydrogen supply and demand response, using units of equipment that each have their own different operating cycles,” a press release from NEDO said.

Hydrogen Society goals

Japan, heavily dependent on imported fossil fuels including large quantities of liquid natural gas (LNG), is attempting to establish a hydrogen supply and demand ecosystem in tandem with developing renewable energy capacity at all scales from residential to utility.

At February’s World Smart Energy Week event, Energy-Storage.news met with exhibitor Enapter, a Germany-headquartered company that claims it is on track to develop small-scale hydrogen electrolysis at a competitive cost. Most hydrogen projects for the grid such as the Fukushima research project above have trended towards greatly increasing the scale of electrolyser projects as a means of bringing down cost. Enapter believes that it has found a path towards making modular systems that can do that instead.

Japan’s influential Ministry of Economy, Trade and Industry (METI), has a roadmap towards affordable hydrogen production whereby it wants to see 1 cubic metre of hydrogen produced from 4.3kWh of electricity by 2030 in order to be competitive. Enapter meanwhile claims it is already able to produce that cubic metre of hydrogen from 4.4kWh.

“So we are actually, extremely close to this goal. Extremely close,” Enapter founder Sebastian-Justus Schmidt said.

“We promise to reach this 4.3kWh, for sure, next year. For us it’s not the next 10 years, we have a clear plan for the next five years. In 2025, almost four years from now, we want to reach €1.5 (US$1.71) per kilogramme.”

It’s a play that has been seen in many other industries, Schmidt said, drawing the analogy with computing. From large mainframe computers to desktop PCs that made the former obsolete, was a matter of modularity and scale. While it’s not exactly the same, Schmidt said, the small-scale electrolysers will not only be improved with each iteration but also are “software-enabled and extremely fast,” he said. Meanwhile the company is seeking premises in Germany where it can start building units on a mass scale.

Anion Exchange Membrane key to Enapter’s low-cost play

Also at the Tokyo show, Schmidt’s co-founder and head of operations, Jan-Justus Schmidt, explained why Enapter believes it has the technological ‘secret sauce’ to go to a price point others cannot with its Anion Exchange Membrane (AEM).

“There’s two established technologies currently: traditional alkaline systems and more advanced proton exchange membrane systems. Both of them have disadvantages. The alkaline system normally can’t operate at pressure, it doesn’t produce high purity hydrogen, so it needs a complicated balance of plant for the purification and compression steps later on.

Whereas the PEM system produces high purity hydrogen directly from the stack and it has a very fast operation and so on, so it has advantages but it operates in an acidic environment so they rely on very expensive materials like iridium and platinum, titanium, which are required to make it work.

With the AEM technology, essentially the cells set up like with the PEM. We have the advantages of the PEM but with low-cost materials of the alkaline systems. That means we can make a low-cost stack, with a bill of low-cost materials and we can have a very simple balance of plant. We can fit everything needed to make hydrogen and put it in a little metal box including control systems, all the water management, all the gas management and so on.”

With this, Jan-Justus Schmidt said he believed “hydrogen much cheaper than fossil fuels in many applications,” would be possible, and certainly that this target made sense for Japan.

“It’s quite obvious you could instead generate as much renewable electricity as you can because that immediately reduces dependence on outside imports of fossil fuels. So it would make a lot of sense for Japan to invest heavily in wind and solar to increase the coverage of what they’ve produced themselves.”

As for a competitive dynamic versus batteries, the Enapter head of operations said he would not say that one was better than the other, with batteries including lithium-ion appropriate for many applications, but “there’s no way around hydrogen is that a molecule of hydrogen is so much more versatile, so much more value than an electron,” with hydrogen then potentially able to be injected into the gas grid, to create synthetic methane or used for heating, transport and industrial process heat.