New technologies and designs aimed at driving down the cost of energy storage facilities are currently the focus of intense industry R&D. Sara Verbruggen reports on DC coupling, an emerging system architecture that many believe will soon become the industry standard, in a paper which first appeared in PV Tech Power’s Energy Storage Special Report 2019.

As the costs of solar PV modules continue to reduce, and those of batteries follow a similar downward trajectory, solar-plus-storage is in growing demand among utilities and solar developers.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The US is leading the trend, where these types of clean energy power stations are starting to produce electricity competitively with gas peaking plants, especially when other revenue streams from grid services are factored in.

To further push down the levelised cost of energy (LCoE) of solar-plus-storage and maximise the amount of megawatt hours (MWh) of solar-generated electricity that can be fed into the grid, energy suppliers and developers are turning to direct current (DC) coupling these installations.

Compared with alternating current (AC) coupling, DC coupling the PV array and the battery storage system in front-of-meter installations, such as utility-scale plants, is a much newer, less standardised approach. This had led some US utilities to begin piloting these configurations to see how the technology performs. On the supply chain side, balance of plant (BoP) equipment manufacturers are delivering more standardised and simpler to use power electronics equipment for enabling DC-coupled plants.

DC- versus AC-coupled solar-plus-storage

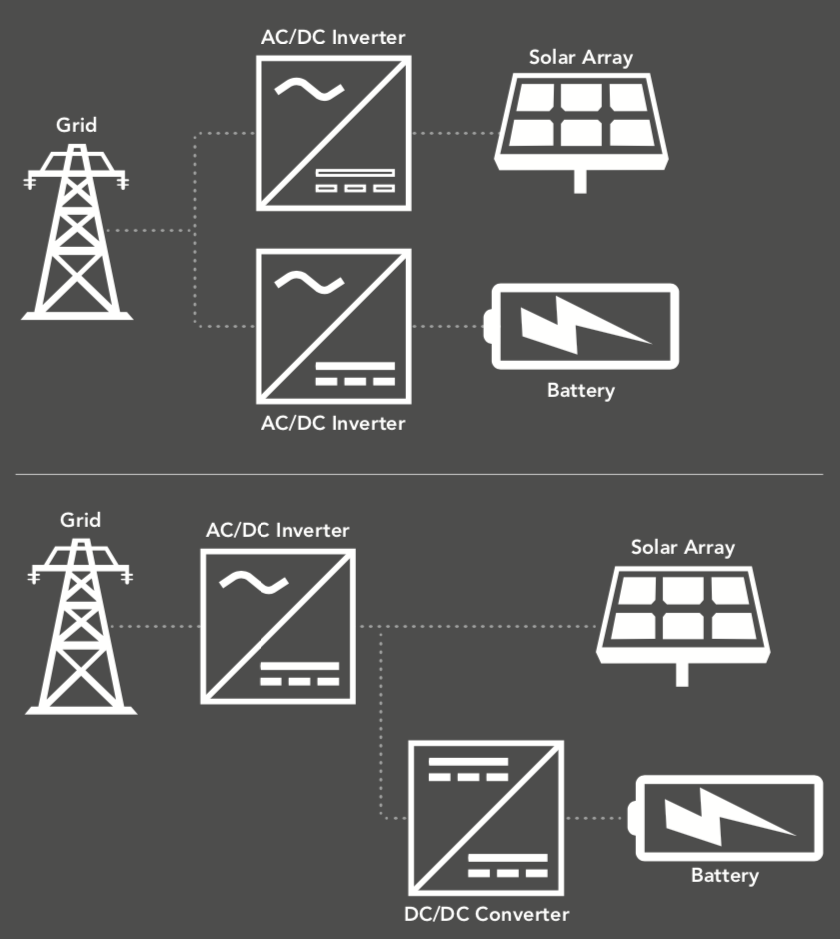

In AC-coupled solar-plus-storage installations there are two inverters, one for the PV array and another for the battery energy storage system.

With this system configuration, both the battery and solar array can be discharged at maximum power and they can be dispatched independently or together, providing the operator with more flexibility in terms of how they operate and dispatch the asset. Located at the same site the solar array and energy storage facility can either share a single point of interconnection to the grid or have two separate interconnections.

In DC coupling, the co-located solar and energy storage assets share the same interconnection, are connected on the same DC bus and use the same inverter. They are dispatched together as a single facility. DC coupling reduces efficiency losses, which occur when electricity current is converted, such as from DC to AC (Figure 1).

According to Wood Mackenzie analyst Mitalee Gupta: “Hybrid approaches emerged in the past where you would see both PV and batteries connected to the grid via one multiport inverter, a configuration more common in behind-the-meter DC-coupled systems. But one of the disadvantages for the front-of-meter market has been cost of multiport inverters.”

The newer variation of DC architecture that has emerged for front-of-meter solar-storage, which Gupta is referring to, is a DC-DC converter. This piece of hardware is tied to the batteries and connects to the PV inverter along with the PV array, allowing for a single interconnection only.

Reduced capex

Since interconnection can make up anywhere between one fifth to over a third of BoP costs, DC coupling can help reduce these costs. Co-locating different assets, be it solar and storage, solar and wind or solar, wind and storage, will always reduce BoP costs, compared with a standalone installation of a solar or wind plant, simply through sharing costs associated with land acquisition or leasing, labour, project management and permitting.

The US National Renewable Energy Laboratory (NREL) estimates that by 2020, BoP costs for co-located DC-coupled solar-plus-storage will be 40% lower and those for AC-coupled solar-plus-storage will be 30% lower.

Business case for clipping recapture

According to analysts IHS Markit, return

to stronger global solar growth in 2019 is occurring, driven by declining PV module prices, which have fallen by 32% on average in the past two years, while average PV inverter prices have also been falling, by 18% over the same period. As the cost of modules continue to reduce come down, DC coupling becomes increasingly advantageous when designing a solar-plus-storage plant, in order to outsize the plant’s solar capacity.

Eos Energy Storage business development manager Philippe Bouchard says: “As well as capturing more cheap solar energy for sending to the grid, you also have a dispatchable power plant and are able to maximise its output too. Power is being fed into the grid in the morning, in the day and in the evening.”

One company that has done modelling around clipping recapture is US power electronics company Dynapower. Through its activity in the energy storage business during the past 10 years, the company

saw the advantage of DC coupling, before developing conversion hardware to enable these types of installations. Dynapower launched the first DC-DC converter aimed at the utility-scale solar-plus-storage market in 2018.

In AC-coupled solar-plus-storage configurations optimal PV inverter loading ratios are around 1.30 for the PV array (DC rating) to 1.0 for the inverter (AC rating). Using the example of a 100MW AC inverter connected to a 130MW DC solar array, the plant’s output is 100MW, resulting in many megawatt hours of clipped energy annually.

Connecting energy storage to the PV array by DC coupling allows for the PV-to-inverter ratio to be significantly increased, and output otherwise clipped and lost

in the more conventional AC-coupling approach is used to charge the battery. According to financial and technical analysis undertaken by Dynapower for DC-coupled solar-storage under the Solar Massachusetts Renewable Target (SMART) programme, an owner of a solar-plus-storage system comprising a 3MW PV array, a 2MW (AC) PV inverter, which is DC coupled to a 1MW/2MWh energy storage system, will be able to capture 265,388kWh of clipped solar energy annually, resulting in US$1.5 million of additional annual revenue, compared with an AC-coupled solar-storage system. The return on investment is estimated to be 5.6 years.

Pilots

Dynapower has worked on several pilots with utilities that are first movers in doing DC-coupled solar-plus-storage installations. These include NextEra and Duke Energy, which have deployed the company’s DC-DC converter technology.

In the Citrus project in DeSoto in Florida, NextEra subsidiary Florida Power & Light has installed a 4MW/16MWh lithium-ion battery system DC-connected to a PV array, which has been in operation since late 2018. The utility is comparing the benefits of the Citrus facility against a 10MW/40MWh AC coupled solar-storage plant, Babcock Ranch, in Charlotte County, also in Florida.

In these pilots NextEra is interested in how storage paired with a PV facility can capture a portion of the solar megawatt-hours that are clipped during peak solar output hours for delivery to customers later in the day.

The utility sees the advantage of DC-coupled solar-plus-storage compared with AC coupling as an ability to capture a greater amount of clipped solar energy, combined with a higher round-trip efficiency (charging to discharging). However, it acknowledges that AC coupling approaches are better known and understood. As both projects continue, NextEra says it will adapt its assumptions.

Dynapower has also supplied its DC-DC converters to pilots undertaken by Duke Energy. They include an installation at Duke’s premises in Mount Holly, North Carolina, as part of a microgrid, which includes a 150kW solar array coupled to a 240kW/122kWh Total (Saft) battery system with Dynapower’s 250kW DC-DC converter.

This August, Duke Energy will commission another DC-coupled solar-storage installation using alternative battery chemistry at its McAlpine facility, also in North Carolina. Eos Energy Storage has supplied a 30kW/120kWh energy storage system, based on its aqueous, zinc battery technology, which is integrated with Dynapower’s DC-DC converter technology.

Dynapower marketing manager Richard Morin says: “These projects are exciting because, until now, what’s slowed the floodgates for DC-coupled solar-plus-storage is that it presents a new technological approach to doing these types of projects, but with these pilots utilities are putting the benefits of DC coupled architecture to the test, ahead of wider adoption.”

To expedite the rollout of DC-coupled solar-plus-storage projects in the future, Dynapower is partnering with large, global manufacturers of central inverters. “We are kind of behind the scenes with our converter. We have designed it to be compatible with different PV inverter makes and pave the way for more plug-and-play type offerings, so we are in the process now of partnering with global suppliers of utility-scale PV inverters, including SMA,” says Morin.

One often-cited disadvantage of doing DC-coupled projects is that the batteries have to be installed in a distributed way throughout the solar array, compared with an AC coupled installation where one central container of batteries is installed.

While it is technically possible to do a DC-coupled central battery storage system, it would entail a high number of long cable runs, making it more practical to co-locate the batteries with the central inverters distributed throughout the installation.

Gupta says: “If a site is space constrained, it may be better to do AC coupled. With DC coupling, blocks of energy storage are distributed over the site and are connected to blocks of storage.”

Other perceived disadvantages of DC coupling, compared with AC-coupling, include increased connection costs. Operations and maintenance costs could also be impacted, if technicians spend time getting to and checking or working on various battery containers spread over a solar field.

However, Morin says: “We have found that in speaking with our customers they prefer containerised distributed batteries for safety and risk mitigation. By distributing the batteries, if there was a thermal event, it would be contained to the singular battery container, reducing the scale of the event and loss of battery assets.”

He adds: “Additionally, the types of large-scale solar installations that we are discussing typically do not require a lot of maintenance. The economic advantages of the DC-coupled approach, such as improved roundtrip efficiency, reduced installation cost and clipping recapture capability, far outweigh any additional costs for maintaining multiple battery structures.”

Demand drivers for DC coupling

According to Fluence Energy’s managing director Daniel Wishnick, the US is the only market where DC-coupled solar-storage is in demand at present. “These types of installations are tax-advantageous,” he says, referring to the federal investment tax credit (ITC).

Gupta says that even with the ITC stepdown in 2021, DC coupling demand will continue as the industry becomes more comfortable with these types of projects and look to optimise revenues from clipping recapture and other streams.

“The number of integrators and working on DC coupled projects is growing, including Fluence, GE and Greensmith, while more vendors are launching DC-DC converters and DC-integrated solar-storage solutions in the past 18 months. That said, at this stage the market has not achieved the same level of standardised, or ‘plug-and-play’ systems that AC coupled projects benefit from,” Gupta says.

Regarding integration, Bouchard points out that the real development work being done with these first projects is establishing the code and control interface to allow a system of components to interoperate seamlessly.

“In a typical DC-coupled solar-plus-storage project, you have the AC inverter, DC-DC converter, energy management system (EMS), battery management system (BMS) and DC solar array operating together to deliver maximum, dispatchable energy when called upon.

In most cases, all these components, including Eos’ own BMS, use the same communication platform and what is known as SunSpec communication protocols, which have been developed by an alliance of solar and storage distributed energy industry companies, including SMA, NexTracker, Engie, Fronius and NEC participants, to support system interoperability.

While there is ongoing development work required in the EMS space to optimise dispatch according to contract or market requirements, Bouchard says that getting these systems to ‘talk’ to each other is not difficult.

“Once you’ve done it the first time, you can leverage the interface development and register mapping to replicate and scale for much larger projects,” he says.

According to Wishnick, specifics of individual projects are influencing decisions on whether to DC-couple or not.

“Site layout, interconnection costs and considerations can all have an impact on whether DC coupling or AC coupling is the best approach to take,” he says.

Fluence is working with several customers, mainly developers of front-of-meter, ground-mounted solar-plus-storage projects, on DC-coupled designs. Most clients of Fluence are at the stage where this is their first DC-coupled solar storage project, indicating the market is still at an early phase.

Bouchard says: “As the US is by far the biggest market for solar-storage, naturally it is where DC coupling is happening first.”

In five years’ time, he thinks it will be more widely deployed in US and also in other markets.

“We are seeing interest in India, Australia and especially Middle East, where you need a large solar-storage plant able to cover the evening load. In domestic terms interest is growing in south-west US and also California, as well as North Carolina, which is one of the fastest growing solar states in the US.”

Bouchard says the company is supplying a DC-coupled solar-storage project in a market outside the US, though won’t provide further details at this stage.

Morin says Dynapower is seeing global interest for its DC-DC converter for DC coupling solar and storage, noting Australia in particular, where electricity market changes are facilitating demand for DC-coupled solar-storage plants.

He is bullish about the prospects for DC coupling. “In the next five years it will be mainstream. If you look at the market research up to 2025, that is the trend.”

SolarEdge readies for rise in demand for DC coupling in residential solar-plus-storage

Another market where DC coupling is seeing more demand is in the residential PV market, where adding batteries increases self-consumption of solar-generated electricity.

According to SolarEdge founder Lior Handelsman, DC coupling behind-the-meter solar and batteries for residential markets results in more energy production and increased return on investment, because there is only the one conversion to AC after energy is discharged from the battery. AC coupling requires three conversions.

“The reduced number means increased efficiency and energy loss is minimised,” he says.

Depending on upfront costs, AC coupling can make more sense when retrofitting an existing PV system to include energy storage. But, Handelsman says: “DC coupling is becoming increasingly popular as more new PV systems are initially being installed with a battery. This is due to decreasing PV and battery costs, increasing electricity prices and evolving incentive structures.”

DC coupling also provides a number of other benefits. “A DC-coupled system requires only one inverter, which means simpler installation and reduced costs. Additionally, one inverter to manage the system means functionality benefits, such as simpler synchronisation and coordination of advanced features,” he adds.

In addition, a DC-coupled solar and battery installation allows the system owner to use PV power above the inverter rating and the inverter does not limit power, in other words act as a bottleneck for the power flow due to energy conversion.

Cover image: Dynapower converters at a microgrid in Uttar Pradesh, India.

This article first appeared in PV Tech Power, Vol20, which is available now to download for free, here.