We can’t afford to become complacent that solar PV continues to enjoy enormous success and energy storage is enjoying successive record years of deployment, if renewables can’t genuinely compete with existing power plant solutions that still form the existing framework of global energy generation and delivery.

For this first blog entry in #SmartSolarStorage2020, a series of themed content that we’ll be bringing you a lot more of during next year on Energy-Storage.news and PV Tech, NEXTracker CTO Alex Au looks at why tackling California’s now-infamous Duck Curve once and for all is a long overdue mission that needs completing – and how we can do that.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Scaling up clean energy and unleashing technology solutions

The growth in renewable energy and clean tech is a terrific story which inspires optimism, but it can overlook how much more opportunity exists in scaling up and supporting the power plant of the future. Until then, we’re leaving areas of optimisation and innovation on the table that would allow renewables to further outperform traditional power plant generation capabilities.

Too often, those involved in energy distribution think about each component in the system and not the overarching solution or the customer’s needs. The solution is getting electrons onto the grid.

You can’t standardise the solution, if you’re just thinking about components.

To use an analogy from the computer industry, the renewable energy space sometimes does the equivalent of building our own computers, choosing separate CPUs, motherboards and video cards, then constantly downloading new drivers to maintain compatibility and keep the PC running effectively.

Just as Dell and Gateway helped streamline the PC process by delivering a holistic ‘turnkey’ computer solution to consumers, renewable energy companies can lead this next evolution, rethinking the power plant design process from top to bottom. A better plant construction process, standardised inverters, and optimised supply chains that can take full advantage of software solutions.

It’s been 20 years since the grid underwent a true optimisation of its software infrastructure. We are long overdue for a fresh look at the power plant level.

Construction and equipment rules should accommodate demand

The construction of a power plant is itself an archaic legacy process inherited from the fossil fuel sector that, in our opinion, stifles innovation in the energy industry!

An asset owner gets bids from EPCs, who then seek to control costs throughout the process. The asset owner’s hands are tied from the start, potentially limiting the plant’s capabilities.

State regulations can also hamstring renewable businesses capable of offering more robust end-to-end solutions. The California Energy Commission has established eligible equipment requirements that limit choices on module inverters, meters and other components.

Currently, only AC meters are approved, so companies can’t put a DC meter with its DC-coupled energy storage. UL certifications haven’t yet addressed this issue, which could become more problematic as energy storage deployment continues to grow.

Breaking down the ‘inverter obstacle’

Perhaps the biggest issue in the way of companies scaling up and delivering future-proof clean energy solutions for the grid is the patchwork of inverters on the market. Each is as unique as a snowflake and the rest of the plant’s distribution equipment has to accommodate its individuality.

If the inverter breaks, you only have one replacement option. If the inverter manufacturer goes out of business, you have to change the system to accommodate an entirely different inverter.

An important fix would be to optimise all inverters to operate at a standard fixed voltage, of say, 1350V, at all times – and control and / or optimise PV panels and batteries for that same voltage. Doing this would better allow distributors to put excess capacity into storage during non-peak hours, rather than curtailing solar (and potentially other renewable) generation. Ideally, voltage alteration should happen at tracker or module level to better optimise operations.

This would also facilitate service and equipment compatibility over the life of the power plant asset.

Software platforms that can power the future

Let’s go back to that CPU analogy. In our industry’s current state, we are leaving the software optimisation – the most important part of the system – to the asset owner. While in theory it may make sense, in practice, this approach is not scalable because every power plant is built with different components. In this disjointed system, a renewable energy company is not able to optimise for what its utility customer seeks.

In a holistic approach, which includes software, we get a system like NEXTracker’s TrueCapture™. The intelligent control system tracks when an area is shaded, when there are clouds overhead and integrates other conditions that may impact solar energy availability and the optimal angle for panels.

Each tracker row has hardware to command what it does and gathers 13 data points every five minutes. When paired with energy storage, the data flow to inverters generates 30 times more information throughput. If a system like ours could be deployed from end to end, it could manage terabytes worth of data that tell a complete story of the energy demand throughout each day. It would increase a power plant’s energy yield by 2 to 6%.

If power plants were structured in a way that allowed a solution such as ours throughout the grid system as is, the additional yield would be equivalent to the energy generated by a typical nuclear power plant, in our case, just by optimising how software is integrated into NEXTracker’s existing infrastructure of over 25 GW of trackers delivered or under active fulfilment worldwide. Now imagine adding that optimisation to energy storage and other units, and you see that the potential is substantially larger.

That’s four additional nuclear plants of energy just by optimising how software is integrated into our existing infrastructure. Now imagine adding that optimisation to energy storage and other units, and you see that the potential is substantially larger.

Let’s unleash the true potential of renewables

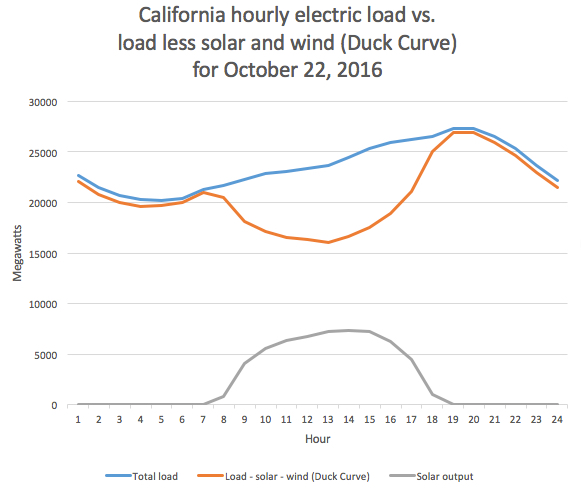

A fully optimised smart grid would not only increase yield, but also empower renewables to change how the entire grid responds to demand. Currently, the grid operates on a fossil fuel baseload dynamic, which is reliant on peaker plants during surges in demand.

A grid built around the end goal of getting electrons on the grid in the best manner possible, led by solar and wind, could be load following. Instead of burning through fossil fuels at all times of the day, renewables could power up or down, putting energy onto the grid or into storage, automatically adjusting to demand with the precision of artificial intelligence.

We aren’t there just yet, but we can be.

In order to scale modern and clean power plants, we must take a holistic approach that includes building a better plant construction process, standardising inverters, and optimising supply chains that can take full advantage of software solutions.

I will continue to explore what this looks like, in upcoming posts that uncover – through discussions with industry leaders and experts – how to better educate utility customers, create effective codes and standards and plan for the constantly changing utility market needs.

Editor’s note: As we kick off the New Year, Energy-Storage.news and PV Tech will be talking #SmartSolarStorage2020. Use the official hashtag on your social media channels to join and follow the conversation.

#DefeatingTheDuck

Note: Some minor edits have been made to clarify technical details in this piece since publication, at the author’s request.