As electrical energy storage Europe (ees Europe) winds down for another year, here are some notable announcements made at and coinciding with the event.

Intersolar Europe has been a fixture on the solar PV industry calendar for over 30 years, while its co-located companion dedicated to energy storage has just celebrated its eleventh year after first being held in 2014.

Despite its relative youth, ees Europe has grown fast, and the expo is now equally considered a must-attend event, with an accompanying conference strand.

The launch that has likely attracted the most attention was, as reported by Cameron Murray for Energy-Storage.news from the show yesterday, CATL’s 9MWh TenerStack battery energy storage system (BESS).

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

For rival BESS technology providers, while much of the emphasis was also on increasing energy density, lowering footprint and simplifying installation, other features and innovations were also highlighted.

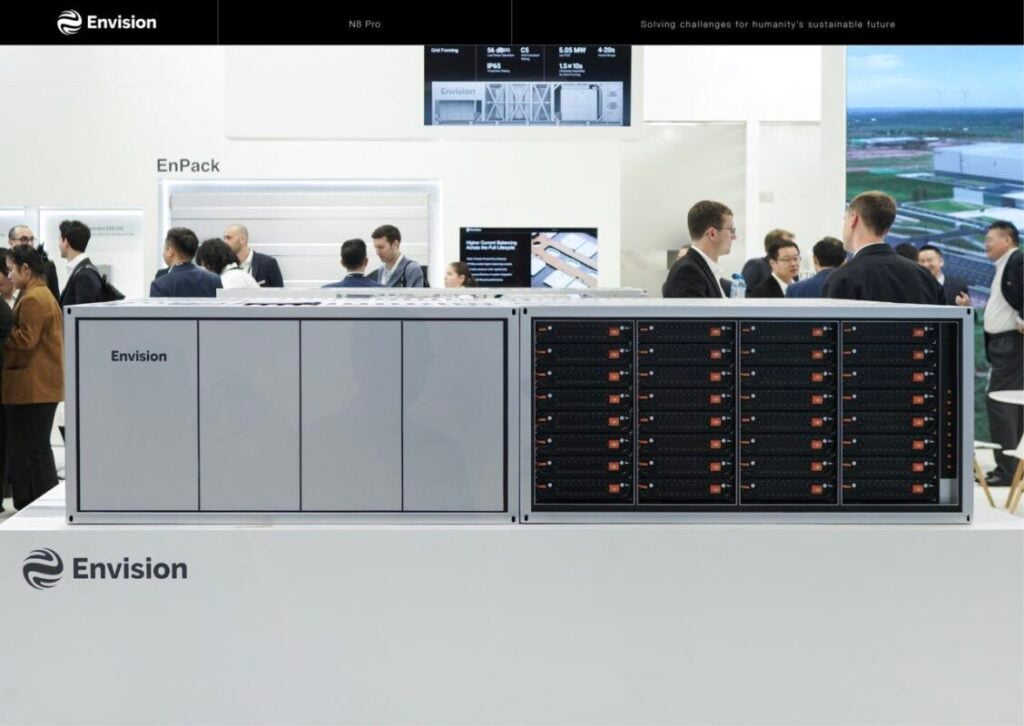

Envision’s >8MWh EN 8 Pro

Chinese BESS, wind turbine and green hydrogen solutions manufacturer Envision Energy launched its next-gen solution, EN 8 Pro 8MWh DC liquid-cooled Energy Storage System.

The company said the capacity in fact exceeds 8MWh, while bringing a 26% smaller footprint for the 4-hour duration model than predecessor models and 12% lower auxiliary power consumption.

It uses 700Ah-plus battery cells and Envision claims it is integrated with precise State of Charge (SoC) algorithms and millisecond-level data acquisition to enable the optimisation of energy management “in real time.”

In addition to high energy density and performance, there was also a focus on a “prevention first” safety approach in the company’s announcement. EN 8 Pro features three levels of fire suppression with active and passive deflagration control, along with AI-IOT early fault detection and a patented triple-fuse technology.

‘Made in Europe’ BESS solutions from LG ES and IPS

Korean battery heavyweight LG Energy Solution showcased its latest lithium iron phosphate (LFP) battery integrated DC storage system.

The company highlighted the 20-foot containerised system’s technical features, including liquid-cooling technology and cells with long cycle life (15,000), but the most interesting aspect was LG ES’s ‘Made in Europe’ claim.

The units, from the cell to the system, will be produced entirely at the LG ES factory in Wroclaw, Poland, with production set to begin this year.

The manufacturer has repurposed some of Wroclaw’s existing production capacity for electric vehicle (EV) batteries to make stationary ESS products in response to market demand, as it is similarly doing with a factory in Michigan, US.

LG ES will also make its products for Europe’s home battery storage market, including cells, in Poland. In addition to ensuring stable supply and faster delivery, this will also make compliance with European Union (EU) regulations smoother, the company claims.

Speaking of regulation, LG ES also showcased the pilot of its Battery Passport, a QR Code-based supply chain and sustainability labelling system, which will be required from February 2027 under the new EU Battery Regulation (2023/1542).

Combining both high energy density claims and a ‘Made in Europe’ tag, is EXERON X-BESS 8, a new BESS solution from Bulgaria-headquartered energy tech and microgrid company IPS.

Currently available models of EXERON X-BESS come in 5MWh and 6.5MWh configurations, but the new model showcased at ees Europe features 8.1MWh battery capacity with an integrated 4MW inverter within the standard 20-foot containerised form factor.

“Leveraging our decades-long experience in turnkey microgrid solutions servicing critical loads, we have engineered an all-in-one system addressing key constraints of BESS project development and operation,” said IPS CEO Alexander Rangelov.

It features smaller cells than Envision’s product, using 314Ah LFP cells with a claimed 12,000 charge/discharge cycle life. An automated manufacturing facility will open next month in Bulgaria’s capital, Sofia. It will have an initial 1.5GWh annual production capacity, ramping to 3GWh by the end of this year.

Saft’s new Intensium I-Flex: 300% daily throughput claim

TotalEnergies subsidiary, French battery and BESS manufacturer Saft, brought a new solution to its Intensium BESS range for which the emphasis of marketing materials was on its thermal management technology.

While not scaling the same dizzy heights of energy density as some other products on show, Saft says Intensium Flex (I-Flex), available in 3.4MWh, 4.3MWh and 5.1MWh configurations in a standard ISO container size, is capable of up to 300% daily throughput.

This is enabled by enhanced thermal management, which allows for high throughput even with what the company calls a “highly compact assembly of battery modules.” The thermal management system includes cooling for modules and cells and an integrated heat exchanger cooling circuit.

The DC version of the liquid-cooled LFP system goes into production this year with an AC version to follow in 2026, and Saft claims it has already booked more than 1GWh of orders. Intensium Flex will be manufactured at sites in China and the US, using dual supply chains.

The company says its modular design allows for parallel connections, which makes it suitable for applications requiring durations from 2 hours to 8 hours.

Powin’s Pod Max ups energy density by 25%

Also exhibiting was US-based system integrator and manufacturer Powin, which has just launched its new 6.26 MWh solution, called Pod Max.

The company claims Pod Max ups the energy density from Powin’s previous 5MWh iteration by 25% within the same liquid-cooled 20-foot containerised form factor.

Powin also says the new product reduces the need for cabling and connections for every megawatt-hour deployed, saving time on installation as well as maintenance costs during system lifetime.

As with previous Powin products, Pod Max features the company’s Stack OS platform, which combines integrated battery management system (BMS), energy management system (EMS) and thermal management system (TMS) technologies. The company claims this enables real-time monitoring and control down to the cell level.