We spoke with Dr Matthias Vetter, head of department for electrical energy storage at the well-respected research and testing institute Fraunhofer ISE at Intersolar Europe / ees Europe at the beginning of this month.

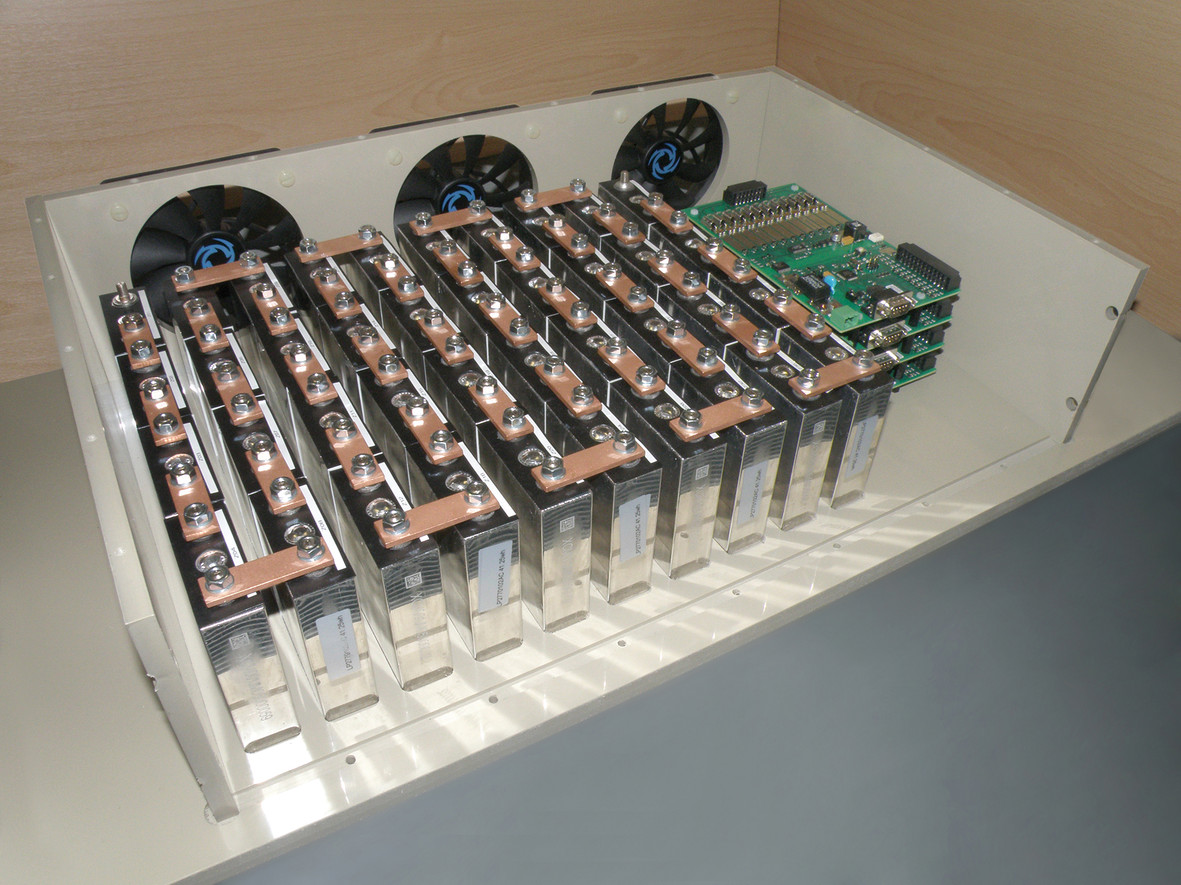

Dr Vetter told us that the work his department does, working approximately 90% of the time with lithium-ion battery systems, includes looking at safety and system lifetime aspects of energy storage, like developing cooling systems and thermal management for batteries. Fraunhofer ISE also endeavours to develop quality assurance measures.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Ultimately, as well as determining how long systems will last in the field and how well they will perform versus manufacturers’ claims, Vetter told us that the “financial and insurance sectors are asking for risk mitigation” for energy storage projects.

“We are talking about new technology which is in the field now but we only have long-term experience with laptops, mobile phones, but not in applications in the electric car, not stationary applications, not utility-scale or home storage systems, commercial systems, we only have long-term experience with lead acid and nickel-based batteries but not lithium-ion batteries.

“This is why the financial and insurance sector is faced with a lot of uncertainties and we try to help them to get more convinced to invest in these projects and therefore as I mentioned, risk mitigation is a key issue.”

Dr Vetter also explains:

- How energy storage has changed from a pure off-grid solar topic decades ago to embrace both on- and off-grid applications

- The importance of battery management systems in giving a clear picture on the state of charge of batteries as well as their “state of health”

- How quality assurance measures contribute to reducing the levelised cost of storage (LCOS) “which then makes the system bankable”

- Why high energy density cells of the type used in EV production are suited for entirely different applications, usage profiles and life cycles to stationary storage

- Why the lack of standardisation could “destroy the economics” of energy storage projects

- Prospects for widespread recycling of lithium-ion batteries and energy storage system components, including “2nd life” repurposed EV batteries

- Market trends Dr Vetter observed at this year’s Intersolar Europe / ees Europe shows