Each battery storage system is a potential source of danger. An ingenious battery management system as well as high-quality cells are the key to a safe operation. For this you need a lot of know-how.

In Austria, photovoltaic (PV) systems with a total installed capacity of more than one gigawatt peak have been installed. Only a fraction of this is equipped with a battery storage system. However, these play an important role in the switch to regenerative energy sources. They enable consumers to use self-generated electricity even when the sun is not shining.

Batteries therefore help to increase self-consumption in households and businesses. In addition, they provide more network stability, as fewer fossil power plants must be kept as a reserve. Batteries are therefore important for a decentralised power supply. But are they safe?

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

KIT provided guidance

Battery storage technology is one of the largest growth markets in the energy industry. But the industry is still very young. Only 10 years ago individual manufacturers produced batteries and connected them to PV plants without regard for safety or quality. The quality of the products available was thus questionable.

For this reason, in 2015, the Karlsruhe Institute of Technology (KIT) in Germany developed “Safety Guidelines for Li-ion Household Storage” in cooperation with leading industrial associations, aimed at guiding the market on safety standards. Since then, much has improved. Yet only a few battery storage devices, including the SOLARWATT MyReserve, have sought stringent external certification to prove that they meet all the safety norms of the KIT guidelines.

Security is the highest priority

Lithium-ion batteries are superior to lead-gel or lead-acid batteries on many levels. Efficiency, depth of discharge and usable storage capacity are all significantly higher. In addition, they achieve more full cycles in their lifetime and have a significantly higher energy density, which has a positive effect on space required for the system and simplicity of installation. Batteries based on lithium-ion technology, however, are also highly complex products requiring maximum care and precision in their development. Safety especially must be guaranteed at all times.

For this reason, some operating limits must be strictly adhered to, to exclude critical operating conditions. The effort and care invested by different battery manufacturers vary greatly. But what are the critical conditions that can arise in a storage system?

Voltage and temperature must be correct

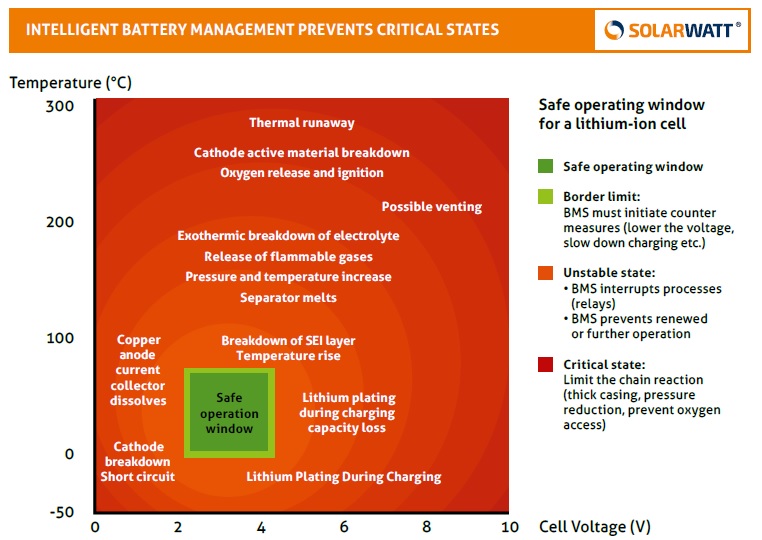

A battery usually consists of numerous cells which are connected in series and / or parallel. Each lithium-ion cell has to operate within narrow limits to ensure safe functioning (see diagram below). Thus, a cell can only be safely operated at a cell voltage of approximately 2.7 to 4.2 volts and within a temperature range of -10 to + 50 degrees Celsius. The exact limits depend on the chemical composition of the electrodes in the battery. A cell that crosses these limits even once must be considered damaged and lead to the final shutdown of the entire battery.

If overcharging occurs due to the battery management system (BMS) not properly controlling the charging process, the electrolyte at the cathode may decompose. This produces combustible gases that can ignite. If, on the other hand, the voltage is too low (deep discharge), chemical reactions form copper ions in the cell. These can form dendrites during a recharging process, i.e. deposits on the electrodes of a battery which can cause a short circuit within the cell.

Chain reactions

Li-ion cells also react sensitively to temperature, both too high and too low. If the temperature in the cell increases too much, for example by a fire near the battery or by an internal short circuit in the cell, an unstoppable chain reaction (“thermal runaway”) can be triggered. There is a risk that escaping gases can ignite a fire or even cause an explosion. Such short circuits in the cell are usually caused by disregard of past critical states: for example deep discharge, charging at very low temperature, mechanical damage or manufacturing defects in the cell production. But how can these horror scenarios be safely avoided?

High quality cells and an intelligent battery management system for precise control

A high level of safety awareness among developers, buyers and production managers must be adopted to ensure that all system components and all functionalities meet the highest safety standards along the entire product development and manufacturing process. The cells used must have low internal resistance and high intrinsic safety. They should only come from manufacturers that meet a sufficiently high standard of quality, best of all with provable automotive industry standard process control.

In addition to careful component selection, intelligent control of the system must also actively prevent the battery from entering into a critical state. If a cell inside the battery module has been previously damaged, the battery management system has to recognise this, mark the cell digitally, and ensure that it can never be put back into operation. Furthermore, the temperature and internal resistance of each individual cell as well as the charging currents have to be monitored and controlled at all times by the BMS. This ensures that the device always operates within predefined safe operating limits and can be switched off under all circumstances in the event of a hazard. The SOLARWATT MyReserve actually goes one step further to provide several redundant high-voltage relays connected in series for safe shutdown under any circumstances.

Strong battery casing: the last bastion

Not only must the software be well thought through – the battery housing also contributes to safety of the system as a final safety barrier. Cells must be protected by a solid, fire-proof casing, for example made of aluminum, so that cells are not damaged in the event of fire or mechanical damage from the outside. If, despite all security measures, hot gases develop and are emitted from the casing, then to prevent a fire igniting, no oxygen must enter the cells.

In the case of MyReserve we prevent this via a housing design with a pressure release valve in which flow velocities are so high that a back diffusion of oxygen into the battery module is nearly impossible.

Data security: Avoiding hacker attacks

The data security of a storage system must also be taken into account by the manufacturer, as a hacker accessing the internal BMS from the outside and changing security parameters could lead to devastating consequences. A radical but ultimately secure solution would be to avoid connecting the storage system to the Internet. This is possible because in the new world of decentralised renewable energy, central access to the BMS via the Internet is no longer necessary. Virtual networks or community electricity can also be coordinated without accessing the BMS, and software updates can also be installed on the spot using a communication cable.

In the case of batteries that are connected to the Internet, a high degree of data security can also be achieved when the manufacturer develops the system with the appropriate high safety awareness by using protocols that allow “read only” access, so data from the Internet can never enter the storage system.

Conclusion

Lithium-ion batteries are innovative and exceptionally powerful systems, but their safe operation requires a lot of research and development know-how on the part of the manufacturers. Only when security is foremost at every development phase of a storage system can potential risks be ruled out.