Sungrow has conducted large-scale fire testing (LSFT) on four 5MWh battery storage units, claiming it to be in industry-first test procedure at that scale.

The battery energy storage system (BESS) arm of Chinese solar PV inverter company Sungrow said yesterday (17 November) that the recent test, overseen by standards and certification group DNV, replicated a ‘real-world power plant fire scenario’.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Fully-charged BESS units were ignited through an induced thermal runaway event and left to burn for over a full day. Sungrow said no propagation—spreading of fire between units—occurred during the test, which was observed by more than 100 invited clients.

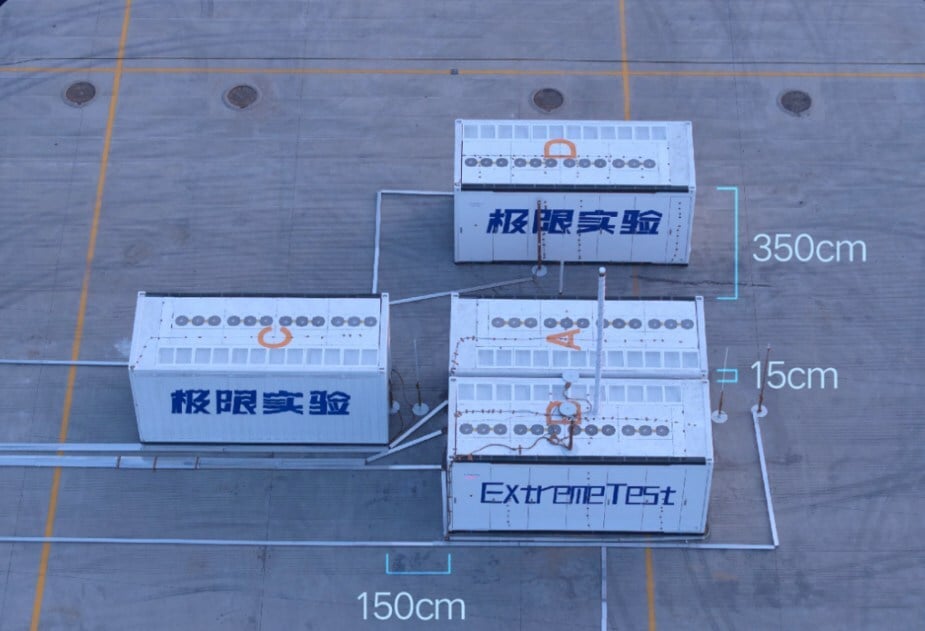

Four units of Sungrow’s latest PowerTitan 2.0 liquid-cooled lithium iron phosphate (LFP) battery units totalling 20MWh of capacity were arranged in back-to-back, side-by-side and face-to-face configurations, as shown in the picture above.

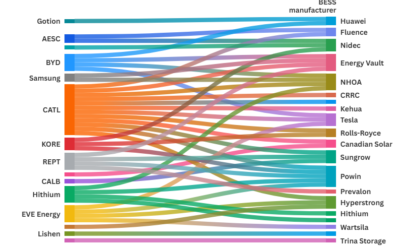

Sungrow has just been ranked number one battery storage system integrator globally by the energy storage research division of S&P Global for the second year in a row.

Large-scale fire testing is not mandatory in codes and standards applicable to BESS projects, even in leading international markets. However, there is a growing recognition that it will be essential to certify that battery equipment can be installed and managed safely even if fires occur.

Essentially, in a large-scale fire test (LSFT), complete BESS units are set on fire and left to burn until the fire consumes all available fuel. Fire suppression equipment is not activated during the testing.

While lithium-ion (Li-ion) battery fires are very difficult to suppress or extinguish with water or chemical agents, if a unit catches fire in the field, manufacturers should be able to demonstrate that the flames will not spread to neighbouring units or other equipment.

Recent research by bodies, including the US Electric Public Research Institute (EPRI), shows that battery storage fires are becoming increasingly rare. However, incidents that do occur should be taken seriously, given that battery storage deployments are rapidly increasing worldwide.

BESS container design and safety features touted

In June, Sungrow set fire to four PowerTitan BESS units, each of 2.75MWh, representing 10MWh of total usable capacity at a third-party laboratory test facility in China, as reported by Energy-Storage.news. The company claimed it to be the first live-streamed LDFT, broadcast to an audience of invited industry and expert stakeholders.

The most recent test cost the company around US$4.23 million, Sungrow said.

The fire continuously burned for 25 hours and 43 minutes, which is far longer than the 4–8-hour combustion tests that the company claimed is more typical throughout the industry.

Despite the lengthy time burning, the container structure of PowerTitan 2.0 units remained intact, and burned-out systems could be hoisted away for removal, while fires did not spread beyond each affected unit. Sungrow claimed this was due to the BESS’ fire mitigation features for advanced explosion venting, flame retardancy and impact resistance.

Sungrow said two containers were placed just 15cm apart, the minimum distance permitted by current industry codes and standards, and far shorter than the usual 3-metre minimum distance for other non-BESS power plant equipment.

Flames reached temperatures of 1,385°C in one of the two containers, but operating temperature in the other container remained at 40°C, which Sungrow said is a safe level. The company attributed this to PowerTitan 2.0’s fire insulation.

The company also said that fire was effectively limited within each container and doors on all four storage units remained intact due to their passive fire protection design.

Fire testing webinar

Large-scale fire testing was the subject of an Energy-Storage.news webinar last week with sponsor CSA Group, a Canada-headquartered standards development organisation.

CSA Group has formulated a new LSFT procedure, CSA TS-800:24, which it hopes will inform and be incorporated into testing regimes and standards. CSA Group technical expert Michael Becker noted during his webinar presentation that the procedure is in line with the principles of LSFT proposed for incorporation into the newest 2026 edition of NFPA 855, the US National Fire Protection Association (NFPA) standard for BESS safety.

CSA Group is currently seeking public comment on the TS-800:24 procedure.

Sungrow’s announcement also follows quickly on the heels of rival system integrator Wärtsilä’s announcement last week of two large-scale fire tests it had done on Wärtsilä GridSolv High Energy and GridSolv Quantum 2 units, two of the solutions in the Finland-headquartered energy company’s Energy Storage & Optimisation (ES&O) product range.

Carried out by CSA Group, Wärtsilä claimed its tests replicated ‘worst-case-scenario’ fire situations, while Sungrow made a similar claim that its burn testing by DNV ‘replicated a real-world power plant fire scenario’.

Another leading global system integrator, Fluence, has also shared information about LSFT it has carried out over the past year or so.

Watch last week’s CSA Group webinar with special guest Wärtsilä, Evolving large-scale fire testing requirements for battery energy storage systems