Rimac Energy, the battery energy storage system (BESS) division of EV supercar company Rimac Automobili, has unveiled its new product at the Energy Storage Summit Central Eastern Europe (CEE).

Roger Moorhouse, product engineering manager for Rimac’s engineering, development and production arm Rimac Technology, gave never-before-revealed details on its BESS solution in a presentation on Day 1 of the two-day event. Details have been eagerly anticipated since the company announced it was going into stationary energy storage back in May.

The unit, called SineStack, is a lithium iron phosphate (LFP) cell-based modular BESS solution with an energy storage capacity of 790kWh and a 400kVa output.

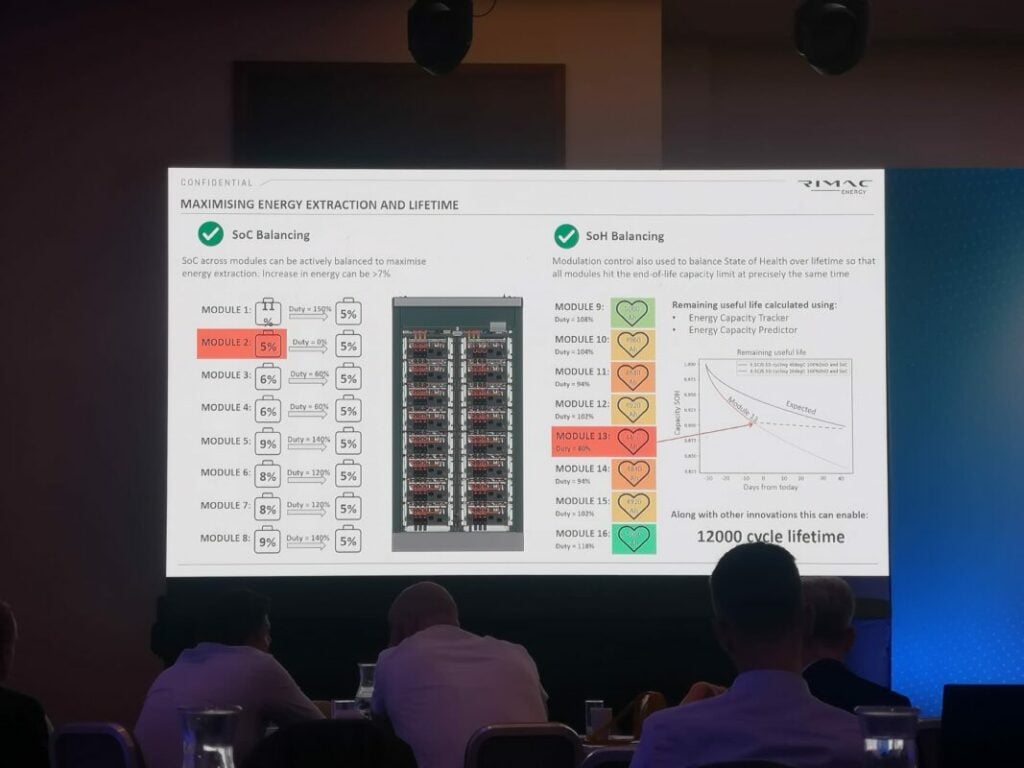

The product’s core differentiating feature is its distributed inverter topology architecture, sometimes called an “AC battery”, where the inverter capability is distributed amongst all of the modules giving independent control over every 18 cells.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

“That means more granular balancing, more redundancy, more energy extracted, longer lifetime, and all of that control to really make it a software-defined product,” Moorhouse said.

Furthermore, he claimed the BESS would have the best cycle life in the lithium-ion BESS industry at 12,000 cycles, the highest AC round-trip efficiency at over 92%, and the best energy density at 280kWh per square metre.

Addressing the audience, Moorhouse later said: “If you’re asking how we can achieve this, it really comes back to the point that we are vertically integrated across the whole system, there is virtually no boundary between the battery and the inverter, it’s highly integrated with reduced filtering requirements, which allows us to get the best footprint (energy density) in the industry.”

Rimac plans to start producing its BESS at mass scale from a new facility near Zagreb, Croatia, with an annual production capacity of 300MWh starting in 2025, rising to 1GWh a year later and 10GWh-plus further down the line.