Battery energy storage system (BESS) integrator and manufacturer Powin Energy will get “priority access” to cells from Rept Battero’s new factory in Indonesia.

Oregon, US-headquartered Powin Energy has answered a few questions from Energy-Storage.news Premium about its 12GWh lithium iron phosphate (LFP) battery cell supply deal with Chinese battery maker Rept.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The system integrator also teased the imminent launch of its new, higher energy density modular BESS solution, which will leverage Rept Battero’s new larger format 320Ah LFP cell.

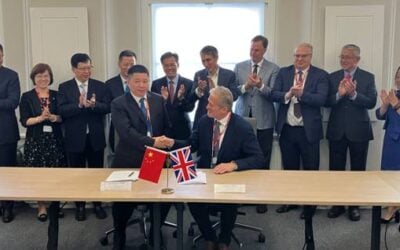

Signed on 29 April, the new framework agreement was described by one source close to the company as a renewal and expansion of the 3GWh partnership signed by the pair a year earlier.

The company has now added in comments to this site that Rept cells will be used for projects in global markets “such as North America, Europe, UK, Australia, Taiwan and others,” noting that Powin has been “impressed by REPT’s cell-level innovations and the company’s collaborative approach.”

A Powin spokesperson said Rept’s level of factory automation was likewise also impressive, as was its environmental controls, and the maker’s “aggressive plan to scale up their production to meet our growing demand.”

Rept cells are already being used at Powin projects that include the 1,680MWh Waratah Super Battery in New South Wales (NSW), Australia, currently being installed for Blackrock-backed developer Akaysha Energy.

Powin has a diversified supplier base that includes at least five different manufacturers. Its original deal with Rept was notable in the industry due to the Chinese maker’s classification as a Tier 2 supplier in Benchmark Mineral Intelligence’s rankings.

Powin has been known to be developing a higher energy density version of its Centipede modular BESS solution, which allows customers to combine multiple units of Powin’s Stack BESS cubes.

Rept has two LFP cell sizes in its Wending product range: 320Ah and 345Ah. The Powin spokesperson said the Wending technology achieves higher energy density than other battery cells within the same footprint, with lower heat generation and higher efficiency.

“Maximising energy density has become a priority in our target markets and results in significant land savings for projects,” the Powin spokesperson said.

They claimed that the “new multi-cell-based hardware platform” that Powin will launch this week delivers 50% increased energy density from the already available Centipede platform. The new platform will be aimed at BESS projects with 2-hour duration requirements or more.

Through its multi-year 12GWh deal, Powin will also get priority access to LFP cells made at Rept’s new factory in Indonesia, at which mass production will begin by the second half of 2025, the spokesperson said.

Procurement challenges in ‘high density, low cost’ era

While some of the procurement challenges have shifted away from the extreme conditions faced by the industry a couple of years ago, as demand and prices for lithium raw materials spiked, diversified supply chains are just as important today, the Powin spokesperson said.

“The COVID-19 pandemic left many integrators stranded as their supply chains dried up and product became near impossible to obtain at a competitive cost. Now that the BESS market is taking off, procuring cells is still a top concern for integrators who lack a diversified supply chain,” they claimed.

Buying from a diverse set of suppliers enables the integrator to closely monitor its partnerships and adjust procurement levels—without causing “major disruptions,” the spokesperson said.

Meanwhile, with the costs of batteries and battery storage systems now declining once again—BloombergNEF recently found for example that the average cost of a 2-hour turnkey BESS in China fell 43% in a year from February 2023-2024—average project sizes have increased.

The company claims the average BESS project in its own pipeline is now 100MW.

“The larger the project, the more cells need to be procured. This can be challenging for companies that lack a diversified supply chain, which is one of the reasons we prioritise a diversity of suppliers,” the Powin representative said.

For obvious reasons, Powin and others have made most of their deals with the world’s biggest battery manufacturers, nearly all of which are based in China.

The company has previously said publicly it would like to see US-made batteries in its supply chain, and the spokesperson said it is now procuring batteries “from global vendors who are establishing manufacturing facilities in key locations across the United States.”

“By doing so, we ensure a consistent and reliable supply of high-quality battery cells, which are essential components of [Powin’s] advanced energy storage platform.”

Energy-Storage.news’ publisher Solar Media will host the 1st Energy Storage Summit Australia, on 21-22 May 2024 in Sydney, NSW. Featuring a packed programme of panels, presentations and fireside chats from industry leaders focusing on accelerating the market for energy storage across the country. For more information, go to the website.