Canada-headquartered start-up Li-Cycle has claimed a victory in commercialising its lithium battery recycling processes, with a shipment sent to a customer just before the end of last year.

Founded in the mid-2010s, Li-Cycle was in 2019 among the prominent advocates for the recycling of lithium-ion batteries. In early June, Energy-Storage.news published quotes from the company claiming 100% of materials from lithium batteries – including cobalt – could be achieved using Li-Cycle’s two-step process.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The company literally shreds batteries to “mechanically size reduce” the devices. This can be done safely even with batteries that still hold charge, Li-Cycle claims. The second step is to then use a hydrometallurgy and wet chemistry process to remove the valuable components and materials one at a time.

Li-Cycle said in a press release last week that the first shipment “of commercially recycled battery material” was completed in December 2019, after processing at Li-Cycle’s Ontario facility. The company affirmed that materials including cobalt, nickel and of course lithium in a shipment that included a concentrate of the energy metals, had been successfully delivered to the unnamed customer.

“The first shipment of commercial product marks a significant milestone for Li-Cycle, on the company's path to becoming a premier resource recovery processor, handling all types of lithium-ion batteries from a broad set of customers and applications,” Li-Cycle president and CEO Ajay Kochhar said.

Renewable, recyclable

Li-Cycle said it is expanding to facilities in the US during this year. Energy-Storage.news reached out to the company today for comment and to make some specific enquiries on the shipment itself, but was yet to receive a reply at the time of publication.

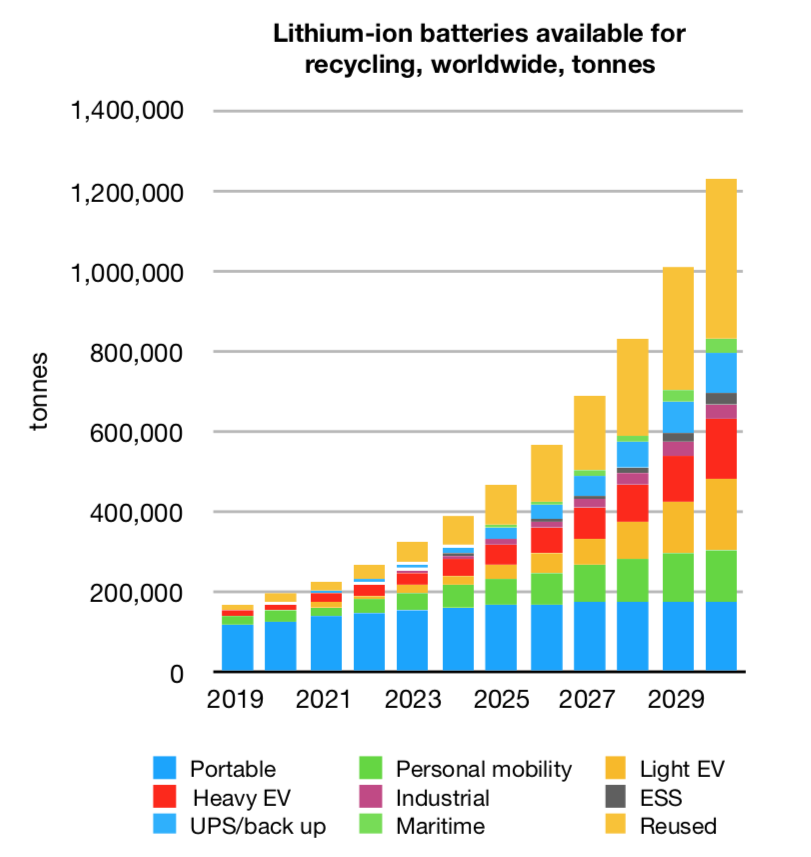

In a 2019 feature article / tech paper for this site and for our journal PV Tech Power, Stefan Hogg, operations and business development for Li-Cycle, wrote extensively about the process(es) and how they work, as well as putting some numbers to both the existing and expected opportunities for recycling of lithium batteries and materials.

While – as with lithium battery production from scratch – EVs and portable electronics are likely to soak up demand for now, Li-Cycle is also confident the stationary energy storage industry will benefit – as will economies and the environment all over the world.

“As a key driver of the transition away from a carbon-based economy, li-ion batteries are integral to the opportunity to drastically reduce greenhouse gas emissions worldwide,” Hogg wrote.

“However, to ensure a truly positive impact over their lifecycle, we must ensure a closed-loop system is in place to safely handle and recycle spent li-ion batteries at scale. This will enable the reintegration of critical battery materials into the li-ion battery supply chain and the broader economy, while preventing negative environmental and safety impacts”.

Read 'Batteries need to be ‘renewable’ too: why recycling matters now', from Li-Cycle's Stefan Hogg, here on the site. You can also download it as a PDF from our 'Resources' page.