Axion Power International, a maker of lead carbon battery systems, has been selected to supply energy storage and frequency regulation to a 9.1MW solar farm in Pennsylvania, the company has announced.

The 9.1MW plant is expected to be the US state’s largest PV generation facility to date when completed. Spanning 19.4 hectares, Coatesville Solar Initiative, as the project is known, received its final land approval in February 2013. Some other local permitting and state regulatory approvals are still required. The plant was originally to be 7.2MW when it was first proposed in 2012, but the project appears to have been expanded since then.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

It will be built over several phases, with the first two phases to be constructed of equal size, 2.4MW capacity each, expected to generate around 6,300,000kWh annually between them. Construction is expected to begin before the end of this year and electricity generated will be sold through a 25-year power purchase agreement (PPA) to the local Coatesville Area School District (CASD), which is already in place.

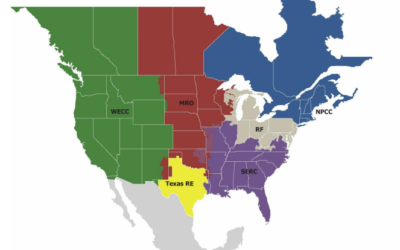

Axion Power uses its proprietary technology, lead-carbon batteries through its trademarked PbC range, which the company describes as a “multi-celled asymmetrically supercapacitive lead-acid-carbon hybrid battery”. The company’s lead acid Powercube product has been approved for connection to the PJM grid, which spans 13 US states. PJM is notable also for having kickstarted a market for frequency regulation within its service areas that has what one analyst described as typically having the “most robust pricing” for provision of frequency regulation services in the US.

Aerial view of the proposed site for Coatesville Solar Initiative. Image: Coatesville Solar Initiative.

While the majority of media coverage, and indeed deployment, of energy storage paired with solar in recent times has been focused on variations of lithium-ion battery chemistry, some makers remain bullish on the possibilities offered by advancements in lead acid battery technology. Earlier this year Trojan Systems unveiled its own proprietary ‘smart carbon’ lead acid batteries for off-grid and renewable energy storage. Trojan and Axion’s adaptations of the technology are expected to compensate to some degree for the less intensive cycling that lead acid can typically handle, compared to lithium-ion based systems.

Axion claims its batteries can be differentiated from conventional lead-acid systems due to their use of negative electrodes that are five-layer assemblies of a carbon electrode, a corrosion barrier, a current collector, a second corrosion barrier and a second carbon electrode. The electrode assemblies are then combined with separators and positive electrodes to make the battery, filled with an acid electrolyte, sealed and connected in series to the other cells. ‘Conventional’ lead-acid batteries simply use simple sponge lead plates.

The company claims that the batteries are tested to withstand 2,500 cycles of charge and discharge, as opposed to other lead acid batteries that can manage around 400 to 600 deep discharge cycles in their lifetime. Under Axion’s test procedure, the batteries go through a cycle of charging and discharging every seven hours to a full 100% depth of discharge.

Axion estimates that as many as 6,000 batteries could be used in total. Image: flickr user: JanetR3

According to Axion chief executive officer David DiGiacinto, around 5,000 to 6,000 batteries could be used at Coatesville Solar Initiative in total when the project is completed. DiGiacinto described Axion’s batteries as “nearly 100% recyclable” and referred to 13 patents protecting the company's technology.

DiGiacinto said Axion was “pleased and proud to have been designated for Coatesville Solar Initiative” and asserted the company’s belief that “the PbC storage and frequency regulation capability will shorten the payback time for the entire installation significantly”.