Energy storage system safety is being taken to new levels, as evidenced by the fire testing efforts of Chinese market players, writes Carrie Xiao.

In recent years, safety incidents triggered by thermal runaway in energy storage systems have accelerated the global upgrade of standards and regulations.

Large-scale fire testing (LSFT), as a critical methodology for ensuring the compliance and market acceptance of energy storage products, provides scientific evidence for preventing and controlling thermal runaway hazards at energy storage power plants, modules, and systems.

Realistically simulating extreme thermal runaway scenarios, it has become a mandatory ‘entry requirement’ for many markets.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

For example, the newest iteration of the US National Fire Protection Association’s NFPA 855 standard, set to take effect in North America in 2026, has already designated large-scale fire testing as a compulsory entry requirement. Driven by such mandatory measures, possessing independent, high-standard, large-scale fire testing capabilities has become a core competitive advantage for energy storage companies in the global market.

Against this backdrop, Chinese companies such as Sungrow, Huawei Digital Energy, Canadian Solar, Trina Storage, Envision Energy Storage, and BYD Energy Storage have successively conducted large-scale fire tests.

Currently, the testing institutions chosen by these companies mainly include UL, CSA, and DNV, with reference to standards such as CSA TS-800, CSA C-800, and UL 9540A.

Large-scale fire testing, as a high-precision and highly reliable comprehensive experiment, poses significant challenges, including high testing costs and considerable technical difficulties. A single test typically incurs costs exceeding tens of millions of yuan and must meet stringent conditions, including a 100% full charge load, extreme spacing, and deactivated fire suppression systems.

Despite this, a growing number of Chinese energy storage companies are joining the testing initiative, voluntarily subjecting their products to fire tests.

What are the differences in large-scale fire tests carried out by battery storage players?

In 2024, Sungrow invested RMB30 million (US$4.18 million) to conduct the industry’s first large-scale fire test in the global energy storage sector. The company intentionally set alight an active PowerTitan 1.0 unit and broadcast the entire process live, aiming to verify the safety and reliability of its energy storage container.

Sungrow collaborated with the testing agency DNV and partnered with authoritative fire safety organisations to refine and establish standards and livestreamed the burn test to over 100 clients. Two separate fire tests were conducted, using four active PowerTitan 1.0 and PowerTitan 2.0 units to construct a real-world power plant for the experiment.

Roger Li, General Manager of Power Energy Storage Product Line at Sungrow, explained that the experiment exposed the energy storage cabinet to extreme heat of 1,385°C—hot enough to melt steel. After burning for a full day and night, the adjacent cells in neighbouring cabinets maintained a temperature of only 40°C. They remained intact, showcasing the fire resistance and thermal insulation capabilities of Sungrow’s energy storage products.

Notably, the test was conducted with all fire suppression systems completely disabled, subjecting the product to the ultimate challenge without any safeguards. This design aimed to verify the system’s inherent fire resistance and its ability to prevent thermal runaway propagation in the absence of any active fire intervention.

Using real-world fire tests to verify the safety of energy storage cabinets is not an isolated case. Similarly, in 2024, Trina Storage released the industry’s first white paper on energy storage system safety as it carried out a large-scale fire test on its energy storage product, the Trina Storage Elementa “King Kong 2”.

In February 2025, Huawei Digital Energy completed an extreme combustion test on its smart string-type grid-forming energy storage system, which was witnessed by DNV and its strategic clients. This test aimed to push beyond conventional industry safety limits through innovative concepts and validation in real-world extreme scenarios.

| Company | Test Product | Test Period | Test Scale | Test Standard | Ignition Location |

| Sungrow | PowerTitan 1.0&PowerTitan 2.0 | 1st test: June 2024 2nd test: October 2024 | 20MWh (5MWh×4 containers) | DNV+Jointly developed with EU/US fire agencies | Middle of initiating battery container |

| BYD | MC Cube | November 2024 | 16MWh (5.36MWh×3 containers) | CSA TS-800 | Bottom of battery cluster |

| Huawei | LUNA2000-4472 Series | February 2025 | 17.88MWh (4.47MWh×4 containers) | DNV | Not disclosed |

| Trina Storage | Elementa 2 | September 2024 | A single 5MWh container | References UL9540A, NFPA855, NFPA69 | Top of battery cluster |

Comparison of Large-Scale Fire Tests by Four Chinese Energy Storage Companies (Chart: Energy-Storage.news)

In June, Canadian Solar, REPT BATTERO, HiTHIUM, CLOU Electronics and Envision Energy Storage successively conducted large-scale fire tests, with the five Chinese energy storage companies joining this ‘burning campaign’ within a single month.

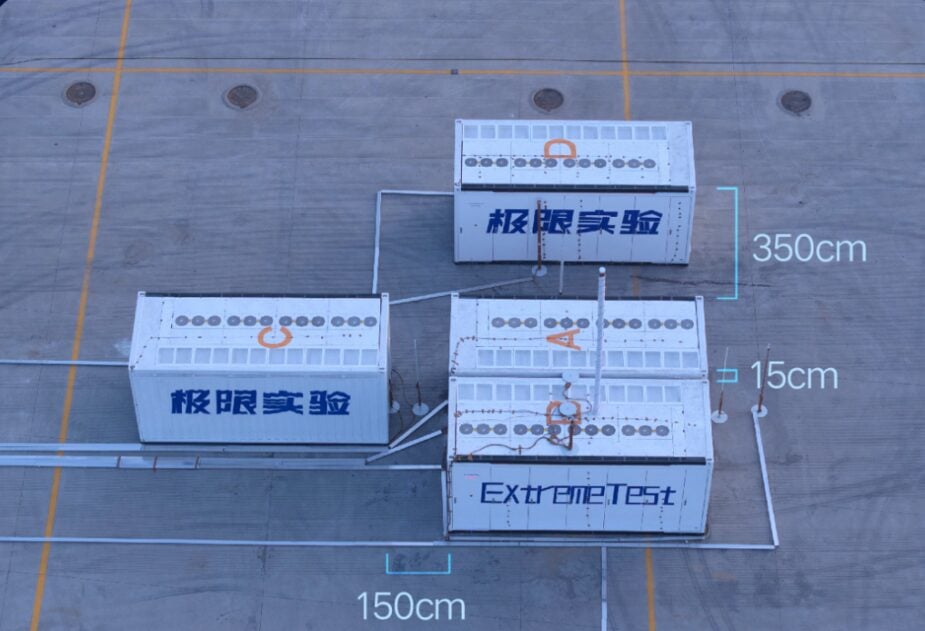

Among these, Canadian Solar’s test on its SolBank 3.0 energy storage system utilised four containers, arranged back-to-back with a mere 150mm spacing. The open flame persisted for approximately 10 hours, yet no combustion or explosion occurred in the containers throughout the test. Results showed that Trigger Container A remained structurally intact after the test, while Target Containers B, C, and D exhibited no thermal runaway propagation, and their internal cells remained stable.

The core objective of large-scale energy storage fire testing is to simulate extreme scenarios and assess the safety limits of energy storage products. Based on disclosed test data, each company demonstrates distinct characteristics in their adopted standards, testing procedures, evaluation metrics and final performances, reflecting differentiated strategic priorities.

For instance, Envision Energy Storage opted for a “closed-door smouldering” approach, fully capturing and treating smoke emissions while testing the world’s narrowest spacing of 5cm between side-by-side and back-to-back containers.

HiTHIUM claimed to have pioneered “open-door burning,” which allows ample oxygen intake to simulate more intense fire conditions.

CLOU Electronics emphasised small-fire control to mitigate the risk of flame spread, with its test lasting up to 59 hours.

C&I energy storage fire testing signifies shift to ‘precision-oriented’ market

In addition to large-scale battery container fire testing, commercial and industrial (C&I) energy storage fire tests have recently emerged as a focal point in China’s energy storage industry.

State Grid Zhejiang Integrated Energy Service Group Co., Ltd. and Sigenergy have successively conducted extreme tests to verify the safety performance of small-scale energy storage systems.

This trend indicates that fire testing is expanding from large-scale energy storage (front of the meter) to C&I energy storage, reflecting the industry’s shift from ‘scale-oriented’ to ‘precision-oriented’ safety management practices. Behind this shift are the dual drivers of explosive growth in the C&I storage market and the lack of safety standards.

In China, the C&I energy storage market has surged in recent years. According to data from State Grid Zhejiang, by Q1 2025, the total C&I energy storage capacity in Zhejiang province had exceeded 2GW, with nearly half of the projects below 500kW. Users tend to deploy standardised 100-125kW energy storage cabinets. These systems are installed in densely populated areas such as factories and shopping malls, where proximity to people heightens the urgency of safety risks.

Against this backdrop, State Grid Zhejiang conducted tests on a 220kWh compact cabinet unit, simulating real-world conditions with an ultra-tight 15cm spacing. Under ‘zero intervention’ conditions, ignition tests demonstrated the system’s ability to achieve “single-cabinet fire containment and omnidirectional isolation” even as flame temperatures peaked at 1,380°C. This breakthrough fills the gap in thermal runaway testing for small-scale energy storage and underscores the urgent need for safety verification in C&I storage.

As the technology matures, fire testing is gradually becoming more prevalent. While large-scale storage testing has established foundational methodologies, C&I storage—with its smaller individual units and higher density—requires tailored validation approaches.

In June of this year, Sigenergy completed an extensive fire test on its C&I energy storage system, SigenStack. The test involved removing all active protection measures, including fire suppression modules and temperature monitoring systems, and was conducted with a minimal spacing of 20-30cm. Results showed that the fire was strictly contained within a single battery pack (containing only 12 cells), with no spread to adjacent equipment. The target cells reached a peak temperature exceeding 300℃, whereas neighbouring clusters remained below 31℃. After 30 minutes, the fire subsided, and post-test disassembly revealed no short circuits, voltage breakdowns, or structural damage.

Unlike large-scale storage fire testing, which focuses on extreme power plant conditions and pursues ‘ultimate challenges,’ C&I storage testing prioritises real-world risks in densely populated areas—a distinction shaped by their application environments.

Additionally, the costs differ significantly: large-scale storage tests run in the tens of millions of RMB, while C&I tests are in the million-RMB range. Currently, only leading energy storage companies can afford these tests, as the financial and technical requirements remain prohibitive for small and mid-sized firms.

Watch Energy-Storage.news’ November 2024 sponsored webinar with CSA Group, ‘Evolving large-scale fire testing requirements for battery energy storage systems’.