Energy-Storage.news Premium speaks with Giovanni Damato, redox flow battery developer CMBlu Energy’s North American President, about using its technology to help meet energy demands.

Redox flow batteries differ from traditional batteries because their energy storage medium is transported by an energy converter. This medium must be flowable.

Their design resembles fuel cells, allowing charging and discharging to occur within the same cell. A key feature of redox flow batteries is that energy capacity and power output can be scaled independently: the cell size or number of cells determines power, while the quantity of the energy storage medium defines total energy.

Liquid electrolytes are held in specific tanks and circulated via a membrane to enable an electrochemical reaction, producing electricity.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

This flexibility can enable redox flow batteries to meet specific needs more effectively than other options. Theoretically, there is no limit to the stored energy, and increasing the energy-to-power ratio often lowers specific investment costs, as the energy medium generally costs less.

In other words, increasing the capacity of stored liquid electrolyte equates to an increase in storage capacity without the requirement for additional cell stacks or power electronics, battery providers claim.

Interest in alternative battery chemistries has grown significantly over the past year.

Geopolitical tensions and new tariffs have introduced uncertainty and driven up costs within the battery supply chain, particularly affecting lithium iron phosphate (LFP) cells imported from China to the US. As a result, many developers are reevaluating their options and exploring alternatives to traditional lithium-based battery chemistries.

Germany-headquartered organic flow battery company CMBlu sees itself arriving at the intersection of market needs, supply chain concerns, and technical requirements.

The company claims its technology has the ability to meet AI data centre demand, remain secure against geopolitical risks, and offer an 8-10 hour energy storage duration.

‘Organic SolidFlow’

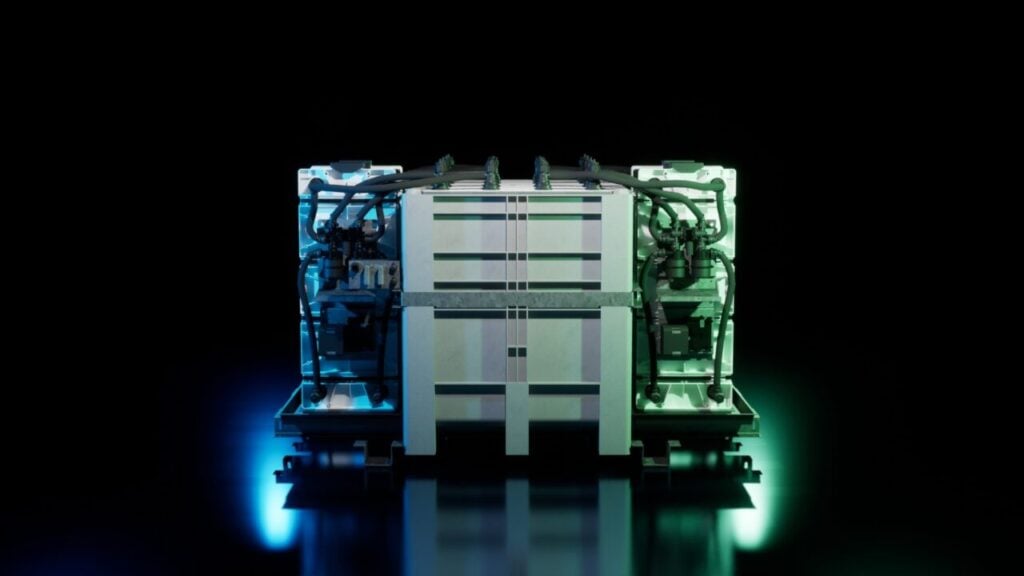

CMBlu’s approach differs from traditional flow battery designs with its ‘Organic SolidFlow’ technology.

Damato says, “At its core, the architecture is like a flow battery with two major twists that we think give us a strong competitive advantage.”

“One aspect is the Organic component, which is carbon-based in chemical terms. This means we are not reliant on conflict materials or rare earth elements, avoiding the geopolitical issues that often accompany discussions about battery metals today.”

He continues, “The other piece is the solid part, or SolidFlow. That sounds like an oxymoron, but if you are familiar with flow battery architecture, there are tanks and stacks, and then pumps which pump fluid through the stacks. Our system has stationary solids in the tank that dramatically improve our energy density.”

Unlike traditional flow batteries that use electrolytes suspended in water, CMBlu’s system incorporates additional energy storage using solid materials within the tanks.

Damato explains, “In a conventional flow battery, like vanadium or zinc, you have suspended metals or the active chemistry in the aqueous solution, in water, and there is a limit to how much you can suspend in the water.”

“What we have done is taken our Organic molecules that are in the liquid, the aqueous solution, the electrolytes, they interact with the solids that are in the tanks too, and then deposit electrons onto the solid. So then you have a much greater energy density than just relying on what you can hold in the water solution,” he says.

Manufacturing and scaling strategy

CMBlu operates its pilot production plant in Germany, which will be capable of producing up to 1GWh annually when fully operational.

The company has obtained substantial funding for expansion, including a €30 million (US$35.24 million) grant from the Greek government within the EU to establish four additional production lines in Greece, outside Athens. This will add another 4GWh of capacity, with construction planned to begin in 2027.

In 2023, the company secured US$107 million from technology and construction firm Strabag. CMBlu and Strabag also signed a preferred partnership agreement.

The company’s manufacturing approach differs from lithium-ion (Li-ion) production requirements. “The skill sets—there is not a particular skill set or a particular type of facility like lithium, where it needs a clean room. It is more like automotive-type manufacturing,” Damato explains.

This flexibility extends to site selection for US manufacturing. “We are kind of open to anywhere in the US. The similarity to automotive manufacturing means it does not matter too much where we are, in terms of the labour pool,” Damato continues.

Addressing data centre demand

The company’s technological growth aligns with growing power demands from AI data centres, posing new challenges for utilities.

Damato says, “Google’s putting in about a 1.2GW-sized data centre in the Phoenix, Arizona area. To put it in perspective, the Arizona utility, Salt River Project (SRP), typically has around a 10GW peak load.”

“We are hearing this all the time for utilities—having more than 10% of their load be one customer is crazy, at least from the utilities’ perspective.”

In 2023, Danish renewable energy firm Ørsted and SRP entered into a power purchase agreement (PPA) with Meta. Meta confirmed that energy from the Eleven Mile Solar Centre would power a data centre in Mesa, Arizona, while the rest would be supplied to SRP customers in the area.

Recently, Google announced a partnership with SRP to speed up the commercialisation of non-lithium long-duration energy storage (LDES) technology. Google will cover part of the costs for LDES pilot projects on SRP’s grid. Additionally, Google will analyse data from these pilots to assess performance and contribute to research and testing strategies.

One of the projects Google will analyse as part of this partnership is CMBlu’s first commercial-scale ESS, a 5MW/50MWh project expected to come online at the end of 2027.

The demand from data centres is driving urgency across the sector. Damato says, “All the hyperscalers that we talk to, I think the general sentiment is that they are disappointed with themselves for not deploying fast enough, and they are even more disappointed with the whole interconnection queue and utilities, how fast they can move.”

CMBlu asserts that its technology is especially well-suited for these needs. Damato asserts, “We can maintain lower costs and be more competitive than Li-ion in the 8 to 10-hour range, which is the main focus, particularly when combined with solar to match the daily energy cycle and the shift.”

The Energy Storage Summit USA will be held from 24-25 March 2026, in Dallas, TX. It features keynote speeches and panel discussions on topics like FEOC challenges, power demand forecasting, and managing the BESS supply chain. For complete information, visit the Energy Storage Summit USA website.