Drew Bandhauer of Leeward Renewable Energy examines how changes in lithium-ion battery chemistries help manage fire safety risk and how industry standards are evolving in step with technological advances.

This is an extract of a feature article that originally appeared in Vol.43 of PV Tech Power, Solar Media’s quarterly journal covering the solar and storage industries.

Every edition includes ‘Storage & Smart Power’, a dedicated section contributed by the Energy-Storage.news team, and full access to upcoming issues as well as the 10-year back catalogue is included as part of a subscription to Energy-Storage.news Premium.

Exploring the critical topic of fire safety in battery energy storage systems (BESS) highlights the advancements in lithium-ion (Li-ion) technology safety. As these systems become increasingly prevalent, understanding how they operate is key to harnessing their full potential safely and efficiently.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Understanding BESS safety: Managing thermal runaway

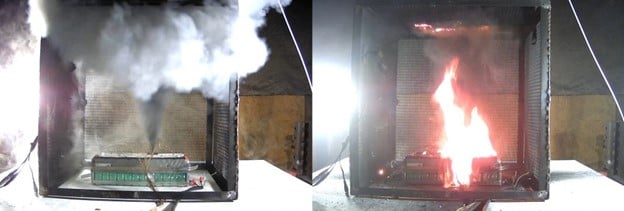

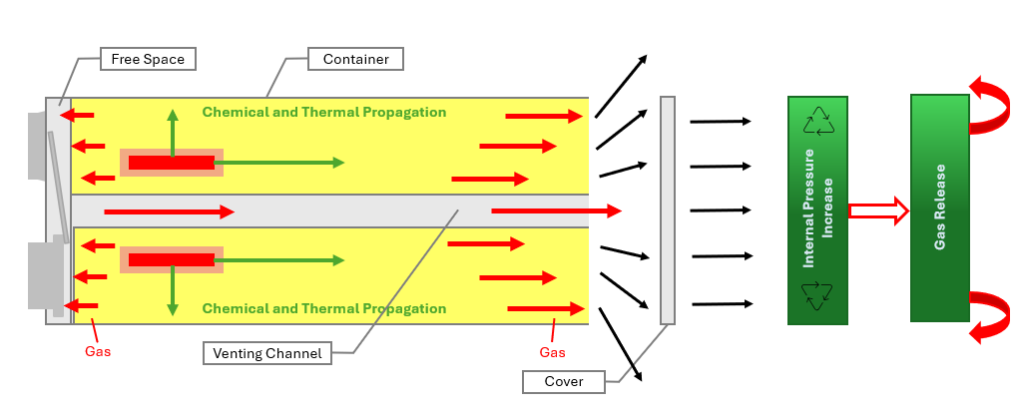

Thermal runaway occurs when a battery cell or module experiences mechanical or electrochemical stress, leading to short-circuiting, high current flow and elevated temperatures. This heat can spread rapidly, causing a “runaway” effect. The key signs of thermal runaway include venting, which is the ejection of hot gases from the cell (see Figure 1). Smoking is often the first visible sign of a problem, as shown in the main image. Flaming, which typically follows smoking, indicates a more severe issue (also see main image).

Ensuring safe operation is essential, and proactive measures are key to managing potential failures safely. Today’s original equipment manufacturer (OEM) battery systems are equipped with advanced safety features that prevent conditions such as overcurrent and overvoltage, critical factors that can lead to system failure.

Robust quality control processes and advancements in battery technology have significantly reduced concerns about thermal runaway. The solid electrolyte interphase (SEI) layer plays a vital role in battery performance by preventing electrolyte decomposition. A well-formed SEI layer, along with regular maintenance and monitoring, can extend the battery’s lifespan by up to 25%. Additionally, technological innovations and rigorous safety standards continue to enhance the reliability of BESS.

These advancements include state-of-the-art monitoring systems that detect early signs of potential issues, proactive and reactive ventilation to relieve pressure buildup and improved insulation between components to limit the spread of heat and fire. Improved cooling methods, such as liquid cooling, also help manage heat in a system to prevent thermal runaway.

With these layered protections and ongoing innovation, today’s BESS solutions are safer, more resilient and well-equipped to meet growing energy demands with confidence.

Comparison of battery chemistries

In the 2010s, with the growth of utility-scale energy storage in the US, nickel manganese cobalt (NMC) chemistry became predominant. Nickel cobalt aluminium (NCA) chemistry held a smaller market share. Within NMC, different compositions were used: higher cobalt content enhanced performance and thermal stability, while higher nickel content reduced costs but affected performance and stability.

Within NMC, various formulations emerged: higher cobalt content improved performance and thermal stability, while higher nickel content reduced costs but introduced greater performance and stability trade-offs.

Thermal event behaviour per chemistry

NMC batteries were commonly deployed before the development of modern safety standards, such as NFPA 855 and UL 9540A. As these standards were adopted, the industry transitioned swiftly to lithium iron phosphate (LFP) chemistry, attracted by its lower cost and superior thermal performance. LFP batteries exhibit a lower flash point and heating rate compared to NMC or NCA chemistries, leading to more favourable results in large-scale fire testing (LSFT).

In contrast, NMC and NCA systems often require additional safety measures—such as enhanced fire barriers or suppression systems—to mitigate thermal event risks. As safety standards have advanced, so too has LFP technology. Its improved performance and enhanced safety profile have made it the leading choice for energy storage applications, supporting a safer and more reliable energy infrastructure.

Current standards and emerging technologies

Between 2018 and 2023, significant advancements in BESS safety practices have been achieved, driven by the adoption of more stringent fire safety standards for energy storage systems.

Key among these is:

• UL 9540: This certification dictates the overall design for the entire system, ensuring compliance in all facets of the BESS, electrical, mechanical, environmental, and system safety.

• UL 9540A: This certification involves tests at the cell, module, rack/unit, and large-scale levels by inducing thermal runaway to ensure no propagation to adjacent units.

• NFPA 855: The primary fire standard guiding BESS site design and installation, supported by critical sub-chapters, including:

• NFPA 68: This standard provides guidelines for designing and installing deflagration venting systems to protect buildings and equipment by safely relieving pressure from rapid combustion events. These vents are reactive to a thermal runaway system

• NFPA 69: This standard outlines the design and implementation of systems and methods to prevent explosions in equipment and buildings, focusing on reducing the likelihood of hazardous combustion events through active ventilation and pressure relief

• NFPA 72: Code outlining safety regulations for smoke detectors, alarm signalling devices, pull stations, heat detectors, fire alarm control panels, and related requirements.

These standards establish essential requirements for BESS design, ensuring that thermal runaway events are confined within enclosures, preventing their spread and effectively mitigating the risk of uncontrolled fires, thereby significantly enhancing site safety.

Emerging technologies such as solid-state and non-lithium batteries are paving the way for safer and more sustainable alternatives, including non-flammable and non-toxic solutions. Non-lithium technologies such as sodium-ion might be poised to replace Li-ion in the same way NMC was replaced in the late 2010s, offering a safer and cheaper alternative and marking a transformative shift in the industry.

The commitment to developing and adopting these technologies reflects an industry-wide dedication to safety, sustainability and long-term resilience. Integrating next-generation solutions strengthens BESS’s reliability while advancing a cleaner and more secure energy future.

As demand for storage grows, BESS is well-positioned to play a foundational role in modern energy infrastructure—minimising risks, maximising performance and enabling a future that is safe as well as sustainable.

About the Author

Drew Bandhauer is a BESS engineer at Leeward Renewable Energy, playing a key role in driving the company’s energy storage initiatives forward. Prior to LRE, he worked at Savion as a project engineer and also spent time at Sunrun as a design engineer, focused on residential applications. He has a mechanical engineering degree from Northern Arizona University.