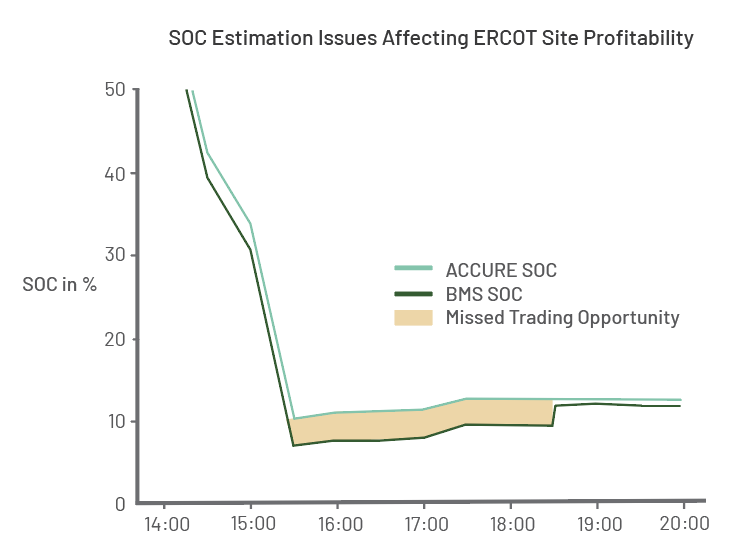

Last summer, a Texas energy storage operator watched in frustration as their battery system missed a golden trading opportunity during a peak demand window. Everything looked good on paper; the system had reported the batteries were nearly a third full, with plenty of energy to sell. But when the moment came, the energy wasn’t there.

The batteries had far less charge than indicated. The result was a failed delivery, a financial penalty, and a big hit to internal confidence in the system. And it wasn’t the first time.

The culprit behind these repeated issues? Inaccurate state of charge (SOC) readings—an increasingly common and costly problem, especially in systems built on lithium iron phosphate (LFP) batteries.

Why SOC accuracy is so difficult with LFP batteries

LFP batteries have rapidly gained ground in grid-scale storage because they offer superior safety, reduced cost, and more stable supply chains than traditional chemistries like nickel manganese cobalt (NMC). However, they introduce a persistent technical headache: estimating their true SOC is exceptionally difficult.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The issue stems from how battery management systems (BMS) calculate SOC. Most systems rely on coulomb counting, which tracks energy moving in and out of the battery, and voltage-based estimation, which maps voltage readings to known charge levels. But with LFP batteries, voltage stays relatively flat over a wide range of SOC (20-85%), making that mapping unreliable.

To make matters worse, LFP cells exhibit a phenomenon known as hysteresis, where the voltage depends not only on the current state but also on the recent charging or discharging history. This behaviour can lead to significant discrepancies in interpreting the battery’s condition.

For example, the same voltage reading may translate into different SOC readings, ranging anywhere from 27% to 62%, depending on whether the cell was previously charging or discharging.

Compounding the challenge, coulomb counting relies on near-perfect current measurement over time, and even the slightest sensor errors add up. This continuous drift in accuracy can cause BMSs to report SOC estimates, which can be up to 30% in real-world LFP battery system deployments.

In energy markets, that level of uncertainty is financially devastating. A recent industry analysis by Modo Energy and ACCURE found that a 20% error in state-of-charge (SOC) estimation can result in revenue losses of up to 11% over a multi-year forecast period.

Cloud-based predictive analytics: A smarter approach

To fix this, leading operators are adopting cloud-based predictive battery analytics. These platforms offer a more comprehensive and dynamic approach to SOC calculation, going far beyond the limitations of onboard BMS.

Rather than relying on data from a single battery in isolation, cloud analytics evaluate fleets of batteries across multiple sites. This broader dataset enables the platform to detect patterns and outliers that a single BMS could never identify. For instance, if one system starts reporting unusual behavior under certain conditions, the platform can compare it to similar batteries in the fleet to pinpoint whether the anomaly is real or just a measurement error.

Cloud-based analytics systems also have far greater computational resources than even the most sophisticated BMS. This allows them to use advanced models that account for battery ageing, temperature effects, hysteresis, and other complex phenomena. These models constantly adapt as they learn from incoming data, providing SOC estimates that remain accurate over time—even under unusual or stressful operating conditions.

Unlike BMSs, which only see one present moment, cloud-based analytics can process and learn from historical trends. This allows them to spot slow drifts or systemic bias. They can then effectively self-correct without the need for manual recalibration, providing stable and trustworthy data over the long term.

In practice, this approach has been shown to bring SOC accuracy within ±2%, even for LFP batteries operating under difficult conditions.

Turning accuracy into competitive advantage

Accurate SOC readings aren’t just about technical precision—they’re about financial outcomes. In the case of the Texas operator mentioned earlier, the transition to predictive analytics delivered immediate results.

By working with ACCURE Battery Intelligence, the operator identified and corrected hidden discrepancies in their BMS-reported SOC. This improvement enabled more confident energy trading, fewer penalties, and a measurable boost in revenue.

The true potential of predictive analytics is unlocked when integrated directly with trading algorithms. Instead of treating SOC insights as external corrections, operators can automate decision-making using near-real-time, cloud-refined data. This ensures energy is dispatched precisely, penalty risks are minimised, and storage assets are used to their fullest capacity—all without relying on outdated safety buffers or guesswork.

LFP batteries are a game-changing technology for large-scale energy storage, but their promise can’t be fully realized without solving the SOC estimation problem. Relying on BMS alone is no longer sufficient, especially in high-stakes markets where timing and accuracy are everything.

Cloud-based predictive analytics offer a proven solution. They combine advanced modeling, historical awareness, and system-wide intelligence to give operators reliable, actionable data about their battery assets. The result: better performance, less risk, and more revenue.

Ready to make your battery systems smarter—and more profitable? Learn more at accure.net.

About the Author

Dr. Georg Angenendt is CTO and co-founder of ACCURE Battery Intelligence, leading the development of a predictive battery analytics platform used worldwide to reduce risk, prevent failures, and extend lifetimes – enabling safer, smarter and more efficient energy systems. Designed by industry veterans for industry veterans, ACCURE’s platform harnesses the flood of BMS data, pinpoints risk and lifetime in real time, and turns complexity into clear, actionable insight.